African Pride

- Business Print Edition

- August 1, 2013

- 0

- 0

- 12 minutes read

Constructing a new GLT in Uganda, Pan African Tobacco Group underscores its commitment to its home continent.

By George Gay

As its name implies, the Pan African Tobacco Group (PTG) has its roots firmly set in the African continent. It employs thousands of Africans at its tobacco processing and manufacturing plants, and throughout its distribution chains, and it supports many others in sourcing its leaf tobacco and manufacturing supplies. In short, its interests are closely tied to those of Africa and its people, and, I suppose, it is true to say that the interests of Africa and its people are closely tied to companies such as PTG.

An example of this close relationship was on display earlier this year when PTG’s founder, Tribert Rujugiro Ayabatwa, announced the investment of $20 million in a new green-leaf threshing plant and warehouse at Arua, Uganda. The first sentence of the announcement included the news that the plant would directly create 700 new jobs—100 permanent and 600 seasonal—and support thousands more throughout Africa. In fact, later it was stated that the project was set to create 150 permanent and 1,000 seasonal jobs once the new plant was fully operational. The plant’s operations will help support 23,000 tobacco growers: 13,000 in Uganda and 10,000 in the Democratic Republic of the Congo (DRC) and South Sudan. And its operations will mean that PTG will have to contract with about 1,500 drivers to transport the plant’s output from Arua to the company’s factories at Kampala, Uganda; Bujumbura, Burundi; Dar es Salaam, Zanzibar, Tanzania; Yei, South Sudan; and Goma, DRC.

The new plant will include a 30,000-square-meter warehouse and a factory for processing up to 10 tons of green tobacco an hour.

But surely one of the most interesting aspects of the project came to light when I asked the question: Is there anything about the plant under construction that is unusual? “Yes,” Ayabatwa said. “PTG is committed to developing the communities where it operates; it positions its plants in areas where there is no basic infrastructure such as water, electricity, etc. …” This was not the usual sort of response to such a question, and it was not the one I had been expecting, but it again illustrated the sort of social investment that PTG seems to making: The plant will simply have to provide water and electricity.

There was little surprise then that Uganda’s state minister for trade, industries and co-operatives, David Wakikona, who was the guest of honor at a groundbreaking ceremony on May 17, described the plant as a landmark moment for the country and region. Calling the new facility a job creator and a timely investment, he praised PTG for its commitment to improving tobacco production and the quality of exports to other regions.

“This factory of such funding magnitude in a rural setting like Arua is a landmark in the history of Uganda,” Wakikona said. It was especially important, he added, because of the jobs that would be created, and because of the associated amenities that would benefit the rural population and put more money into the pockets of local people.

PTG already has a strong presence in northern Uganda, where it invests $18 million a year in tobacco farming. And that amount was expected to double during the next five years to meet demand, Ayabatwa said. “This expansion will allow us to create new, good-paying jobs in an important part of Africa,” he added. “It will also allow us to farm and process tobacco more efficiently and cost effectively. I couldn’t be more delighted with this investment.”

The company buys about 15 million kg of leaf tobacco a year, largely flue-cured, burley and dark fire-cured, from Angola, DRC, Tanzania, Uganda, Zimbabwe and Brazil. Some of the tobacco is sourced from contract farmers, some from PTG’s direct commercial-farming operations, and some from Africa’s auction floors, while the rest is bought under annual contracts with international dealers.

When I asked how PTG ensured, in a competitive world, that it paid tobacco farmers fair prices, Ayabatwa said that PTG believed in the long-term sustainability of the tobacco industry in Africa. “Not only do we make sure that a fair price is paid to both our farmers and small growers, but we also invest in social and environmental responsibility initiatives in the communities where we operate,” he added.

This raised a question about how PTG ensured the tobacco it bought was grown in a sustainable way. “PTG trains and supports farmers and food crops by supplying food seeds and running a reforestation program,” said Ayabatwa.

Strong fundamentals

Currently, PTG has two green-leaf threshing plants, one in DRC and one in Uganda, which thresh and pack flue-cured, burley and dark fire-cured leaf. And the company operates nine manufacturing plants, seven of which have their own primary departments.

The company produces at its manufacturing plants a range of local cigarette brands and five that have a pan-African presence: Forum, Legends, Peterfields, Supermatch and Yes. Most of its cigarettes are Virginia blends, but it offers also American blends. All but one of its cigarettes are filtered, with tar and nicotine levels that vary according to the regulations in the country of sale, but that, generally, are around 10 mg and 1 mg, respectively. Formats include king-sized and 100 mm cigarettes, and packs are both hinge lid and soft cup.

PTG said it was constantly developing new cigarette brands and line extensions, and that it also manufactured roll-your-own and pipe tobaccos. And, like any other tobacco manufacturer, it followed international trends when it came to considering the introduction of alternative tobacco products and, even, e-cigarettes.

The company distributes its tobacco products using what Ayabatwa described as a competitive mix of company-owned and third-party distributors, depending on the country.

Ayabatwa didn’t want to disclose how many cigarettes PTG sold each year, but he said the number was increasing because of growth in the African market. And he seems confident about the future of the tobacco industry. “Despite the anti-smoking lobby, tobacco will always be one of the major, fast-moving products offering pleasure to those who choose to smoke,” he said.

When I asked Ayabatwa whether PTG was a profitable company, he replied that, “on a group level it meets industry standards but reinvests to sustain its growth and development.” And when I further asked whether profit was increasing year on year, he said, “Yes, but this profit increase is used to reinvest in new markets.”

Passing the baton

If these answers sound slightly different—more equivocal, perhaps—than those you might expect to receive from a successful entrepreneur who has built up a group of businesses that, alongside tobacco, include cement, tea, plastic shoes, beer and snack foods, it’s not just that Ayabatwa dares to be different. When, in January, he announced that he was retiring from the daily operations of PTG, he made the point that making money had never been his goal but a means to an end—the end being “building something up, creating something.” “That is what I tried to accomplish, and that is the legacy I leave to my sons and son-in-law,” he said.

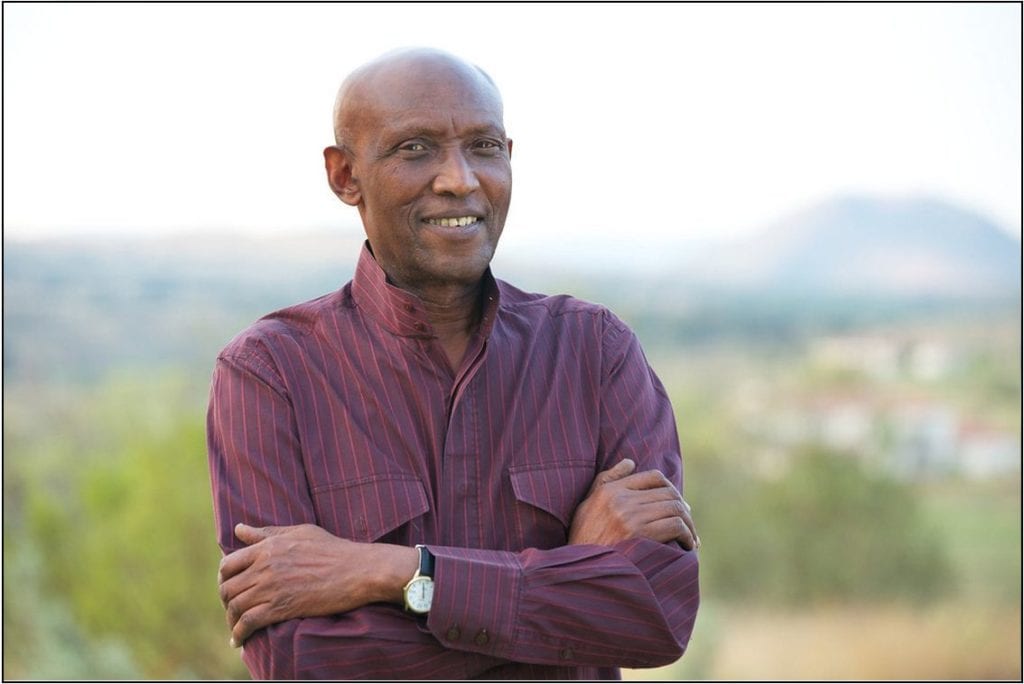

I guess that to say he was successful is something of an understatement. From his roots as a young Tutsi in Rwanda and a refugee in Burundi, Ayabatwa overcame overwhelming odds to build up a group of businesses that employ about 26,000 people (who support about 182,000 people) from South Africa to the United Arab Emirates, from Angola to Tanzania.

But, now, he has left all that to Paul Nkwaya, his eldest son, who serves as the group’s marketing director; his youngest son, Richard Rujugiro, who is technical director; and his son-in-law, Serge Huggenberger, who is financial director.

Ayabatwa is continuing to advise his sons and son-in-law on company management but is also spending more time on his charitable endeavours. Over the years, he has financed hundreds of scholarships for primary, secondary and university students and—along with his PTG companies—has engaged in numerous other charitable works, including donating cement for area infrastructure, providing seedlings and food to farmers and factory workers and offering job training to unemployed African widows.

And, given his background, it will come as no surprise that he is developing a foundation mainly to help aspiring African entrepreneurs. Separate from PTG, Ayabatwa is developing a private, nonprofit foundation to provide startup capital, training and education to aspiring African youth. The foundation will offer internships to African engineering students so they can gain the practical experience they need to succeed.

But, returning to PTG for a moment, I asked how Ayabatwa saw the future for the company. “PTG has established its roots in Africa over the past decades and will continue to grow in line with industry standards and the African economy as a whole,” he said. “We have no doubt that, although it will always retain its African identity with pride, the future of the group will extend far beyond the continent in the coming decades.”