Flexible production technologies may help stem the forgery of cigarette paper booklets.

Contributed

When people contemplate the illicit trade in tobacco products, they usually think about cigarette brands. Less known, but increasingly problematic, is the counterfeiting of tobacco accessories, such as cigarette paper booklets. Established brands in particular are susceptible to this problem, and manufacturers are challenged to come up with ways to prevent the forgery of their valuable trademarks. One potential solution comes from engineering. By applying innovative technologies in the production process, booklet manufacturers can make life considerably more difficult for brand pirates.

When people contemplate the illicit trade in tobacco products, they usually think about cigarette brands. Less known, but increasingly problematic, is the counterfeiting of tobacco accessories, such as cigarette paper booklets. Established brands in particular are susceptible to this problem, and manufacturers are challenged to come up with ways to prevent the forgery of their valuable trademarks. One potential solution comes from engineering. By applying innovative technologies in the production process, booklet manufacturers can make life considerably more difficult for brand pirates.

Today, a wide range of tobacco accessories are available. The time when a roll-your-own tobacco smoker would select his favorite product from only a handful of more or less similar booklets is over. Not only have new products found their way to store shelves; the diversity of individual brands has increased enormously. Do you prefer white, unbleached or green paper? Is your preferred product made of hemp or wood? Have you already picked its size and thickness? In addition, a booklet today often comprises more than just a package with papers. Some include pre-rolled paper, flat tipping paper or even a tray for mixing.

The market for tobacco paper booklets is not only more diverse than it was in the past; it is also growing. A 2010 survey found that more than 10 percent of smokers in Europe use predominantly RYO. Other research suggests that, when cigarette prices rise, smokers are more likely to switch to RYO than to illegal cigarettes. The legalization of marijuana in many jurisdictions has boosted demand for rolling papers, as well.

With a bigger market to share, new suppliers have been entering the market. The development has not gone unnoticed by booklet manufacturing machinery suppliers. “The last six months we have sold and installed platforms outside of Europe, while the installed base in the European market is growing as well,” says Pierre Mousson, managing director of Imatec, which is based in Luxembourg and part of the ITM Group.

“Not long ago, aside from a few big brands, the production of booklets was done mostly by private labels,” he explains. “The number of private labels has grown, and lately a few label [manufacturers] have set up their own production facilities.” According to Mousson, such investments suggest the operations of those manufacturers are profitable, which in turn hints at the strength of the market.

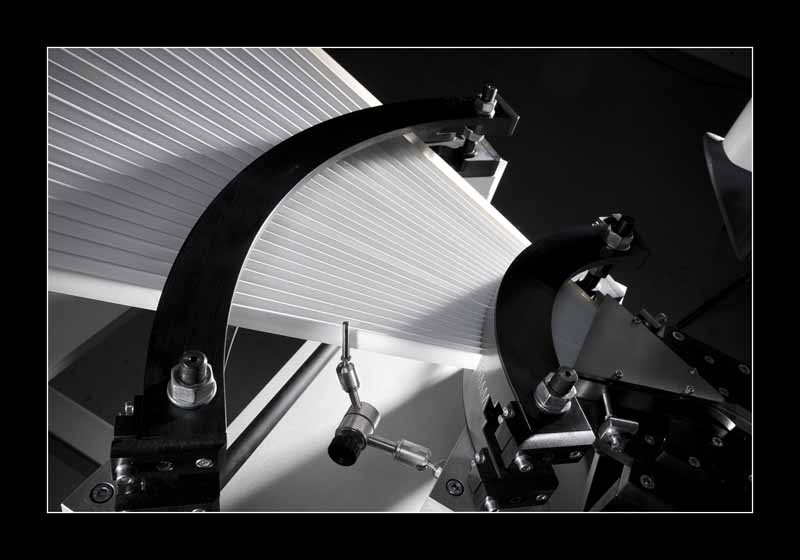

Thanks to evolving technology, setting up a booklet manufacturing factory is easier today than it was several years ago. “If I look at our own booklet platform, we were able to increase the flexibility of our machine tremendously in the last few years,” he says. “This means manufacturers can use the same platform to produce different kinds of paper sizes and switch easily between additional options in the booklets. Therefore, it is easier to reach return on investment.”

But greater flexibility of the equipment is not the main reason for the new brand entries, according to Mousson. “If you look at the booklet market, three kinds of parties can be distinguished,” he says. “Of course, there are the established, large manufacturers. But over the past few years, two types of players have joined them in the market. The first type is looking for a quick win; with striking designs they want to stand out on the shelf and attract mostly young roll-your-own smokers. Their pricing is low, and, quite often, the quality is low as well.”

The second group of entrants will be a bigger competitor to the well-known manufacturers, according to Mousson. “These brands are also giving a lot of attention to attractive design, but [they] are combining it with high quality and the fulfilling of specific demands of targeted niches,” he says.

Especially in developed countries, RYO smokers feel strong loyalties to their booklet types and brands. As is the case with cigarette brands, smokers view the choice for a paper booklet as a statement about their identity.

The combination of brand loyalty and product quality makes these new brands vulnerable to counterfeiting. “For counterfeiters, the largest brands are the most interesting,” says Mousson. “So, when new entries are showing growth in their market share, they will get noticed by copycats.”

Rip-offs have the potential to considerably hurt the brand owner’s sales volumes and reputation. If users don’t recognize the lower-quality booklet as a copycat, they will point their fingers to the legal manufacturer.

Rip-offs have the potential to considerably hurt the brand owner’s sales volumes and reputation. If users don’t recognize the lower-quality booklet as a copycat, they will point their fingers to the legal manufacturer.

“To prevent the harmful effects of counterfeits on the [manufacturer’s] image, it is important that the end user is able to immediately detect that he holds a counterfeit,” says Mousson. “If the end user thinks he has a [genuine] booklet, while the counterfeit is made of a lower paper quality or uses artificial gum, he will avoid buying the more expensive [real] brand in the future.”

Fortunately, the technical capabilities to prevent counterfeiting are growing. “Today, some producers are experimenting with coding on the booklet,” says Mousson. “They are adding a promotional paper, or printing the brand on every rolling paper in the booklet. But these solutions are not watertight, and [they] are making the producer less flexible.”

Watermarking, for example, is typically done by the paper manufacturer before the paper is slit. This means the booklet producer cannot easily change the printing later, giving counterfeiters more time to copy. And for a QR code to be effective, the end user must be willing to scan the code and be able to realize that an error message indicates a counterfeit, which requires consumer education.

Together with its customers, Imatec has been working on better alternatives. “The best way to outsmart copycats is to keep adjusting the product,” says Mousson. “This can be done on the cardboard of the booklet and on the rolling paper itself.”

By letting the booklet machine, rather than the paper manufacturer, print the rolling papers, the producer can adjust the designs almost instantaneously. “Think of printing logos or texts that relate to events in a specific country,” says Mousson. “This will not only make this booklet less interesting for counterfeiters but can also enhance marketing possibilities.”

Comparable solutions can also be deployed on the booklet. “When producers can add and adjust text, shapes and pictures in the booklet producing machine, it will have an immense effect on flexibility,” says Mousson. “It will deter counterfeits tremendously.”

Imatec is constantly designing and developing new solutions to discourage counterfeiters. “As a team, we are proud we enable our customers to outrun the copycats,” says Mousson. “Because of the variety in options that we can build in our booklet platform, we are able to offer every customer his own solution. This makes every platform unique and will give every producer his own advantage in the market.”

This article was contributed by Imatec.

Countering counterfeits