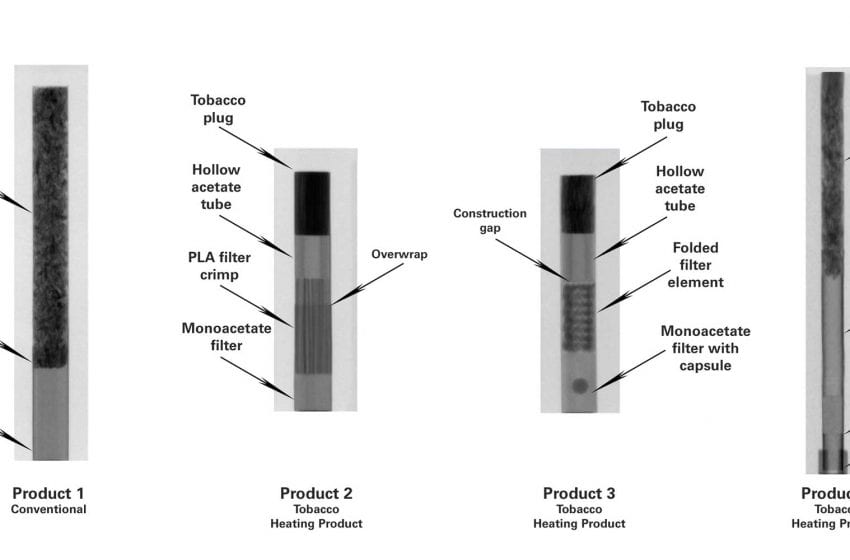

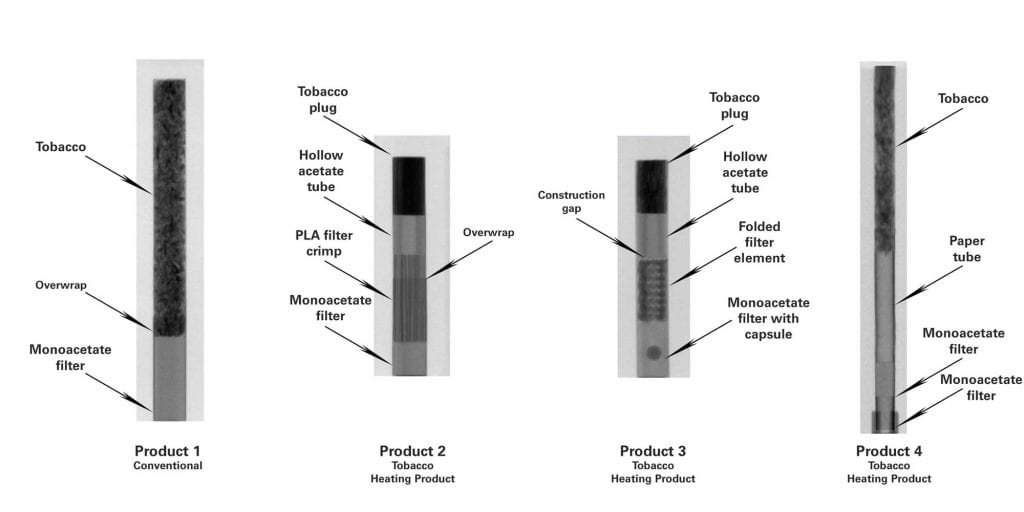

Cerulean has introduced into its Quantum Neo physical test station a shelf capable of routinely and rapidly X-ray imaging cigarettes and filters.

The need arose from the limitations of current inspection methods when testing complex, combined products such as those used for tobacco-heating products. X-ray imaging allows visualization and accurate measurement of the size and position of hidden elements without damaging or destroying the product under test. Compliant with all U.K. radiological protection standards, the fully shielded system is suitable for the factory floor for automated routine product analysis.

Beyond the obvious R&D application, adding the powerful X-ray tool to the Quantum Neo QA/QC stack enables the producer to speed product release to the market with confidence that the constructional features in his products are fully compliant to specification. The power of the tool can be applied to complex tobacco-heating products and conventional products. Location of flavor capsules radially and longitudinally is simple and not limited by the proximity of other capsules or features, such as carbon filters, a significant limitation of microwave systems.

The Cerulean system utilizes a low-power X-ray source and a custom detector array. This arrangement (patent pending) produces a full rod image in less than six seconds. A suite of advanced software tools, automatically applied to the brand specification, measures hidden features’ length and size with an accuracy of up to 20 microns. Additionally, tube concentricity, capsule position and integrity as well as voids and defects can be detected and measured. Thick or metalized tipping paper does not present difficulties of measurement for the system.

The straightforward software tools make this suitable for use by operators and technicians as well as laboratory scientists.

This novel hardware configuration is both robust and competitively priced when compared with more conventional standalone systems such as CAT scanners.

Integrating the X-ray shelf (designated “Q” by Cerulean) into the Quantum Neo test station provides a powerful analytical tool when coupled with more conventional measurements, such as PDV, size or weight measurements, with the added benefit of leveraging other Quantum Neo capabilities, such as autosampling from the mass flow or from a GD combiner for the ultimate in QA measurements.

Orders for Quantum Neo containing the Q shelf can now be taken on standard lead times.