Filter manufacturers prepare to meet new environmental requirements and consumer preferences.

By George Gay

A major challenge for the cigarette filters industry this year, and, by extension, for the cigarette manufacturing industry, will involve the phasing-in of titanium dioxide-free (TiO2-free) acetate tow. In an email exchange in January, Georgi Zisov, sales director at the Bulgaria-based cigarette filters and print house company Yuri Gagarin, said that, initially, the requirement that cigarettes were manufactured with TiO2-free filters would apply only to those destined for sale in the countries of the EU where the requirement was due to come into force in October. But, he added, it would prove inefficient for tow producers, filter manufacturers and end users to deal simultaneously with both traditional and TiO2-free tow, so, starting this year, there was likely to be a push for the adoption of filters made with TiO2-free tow across all markets, something that would probably be achieved within a few years, allowing those involved once again to enjoy economies of scale. Yuri Gagarin, Zisov said, had already started trials with TiO2-free tow for a number of customers both within and without the EU.

TiO2, which is used as a bleaching agent to make tow appear whiter, is considered to be harmful to health, something that, to my mind, raises a number of questions, not the least of which has to be why, therefore, is it used in some food products and toothpaste? OK, perhaps the form used in these products is different to that used for bleaching, though, having said that, TiO2 was banned from foodstuffs in France last year.

Nevertheless, I think it is worth asking if it is believed that the health concerns raised by the addition of TiO2 to filters—where it is presumably heated but not burned during the consumption of a cigarette—is separate from or merely part of the “deadly” risk posed by inhaling the smoke from the combustion of the tobacco rod and paper? If it is considered to be part of the overall risk, it would seem to me, admittedly somebody untrained in chemistry, that the argument for removing it from the health equation does not stack up, at least at the level of the individual smoker. In this case, it would seem likely that the removal of TiO2 could be said with any degree of certainty only to change the health risk because, due to the complex chemistry involved, it would surely not be known whether that risk had been lowered or raised. There would, of course, be a better argument for removing TiO2 if it presented a known separate and additional risk, though it is difficult to understand how such a separate, additional risk could be demonstrated at this time, if ever.

And there is a side issue here. The undesirability of raising the risk is obvious, but lowering it could suggest to consumers that cigarettes were now less risky than they were previously, leading to a surge in consumption.

No quick fix

None of this is to suggest that removing TiO2 is not a good idea. It probably is, but I feel that it is necessary to try to understand our motives, even if we have to admit that they are based on a gut feeling. I buy unbleached coffee filters on the basis of a vague idea that not bleaching the paper used in their manufacture might extend by a millisecond the date at which the earth’s ecosystems finally collapse under the weight of human indifference.

But perhaps that’s not fair. Asked what the main factors were that drive the global market for cigarette and roll-your-own (RYO) filters manufactured by specialist suppliers, Seng Keong Low (SK), global marketing manager at Essentra, told me that these comprised consumer preferences legislation and customer demand.

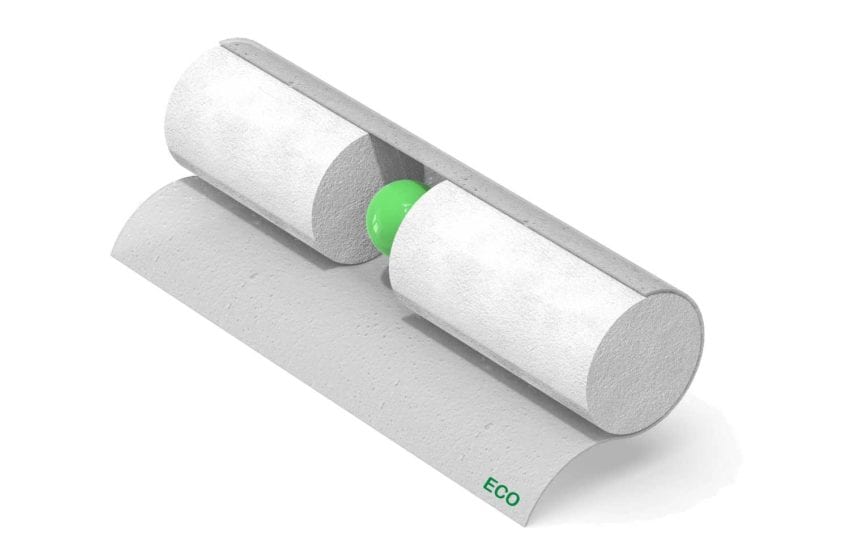

“For example, single-use plastics legislation, particularly in the EU, has brought sustainability to the forefront of consumers’ minds,” he said in an email exchange. “Due to the pending restrictions on plastic filters and the evolving consumer preferences for a more eco-friendly option, paper-based and other nonwoven alternative materials will be the future of the industry. As such, Essentra has invested our innovations efforts in finding a more sustainable option and recently launched three new plastic-free filters in our ECO range” (see sidebar).

But things are not as simple as they might sometimes seem to be. “There has also always been an incongruous relationship between the tobacco industry and environmental, social and corporate governance initiatives,” said SK. “Despite this, we at Essentra believe in being the pioneers to drive the industry to go green by launching nonplastic alternatives to address the issue right from the source.

“However, we are also very cognizant of the fact that while providing a nonplastic alternative is a step in the right direction, it will ultimately come down to the consumers’ willingness to make the right choices as well. Based on positive indications from our own consumer research, we expect a slow start, but as more momentum and positive sentiment builds up, a snowball effect will rapidly accelerate the shift toward a green alternative.

“In the end, there is no quick-fix solution, and the initiative to educate and convince consumers will require the cooperation of and collaboration between regulators, cigarette manufacturers and tobacco products manufacturers, and we at Essentra are proud to be the ones to take the first step in this journey.”

One problem here is that consumers are not necessarily the good guys. Whereas industry players have a role to play in improving the environmental credentials of cigarette filters and in consumer education, it is only consumers who can stop discarding filter butts in an anti-social manner. The gains made by switching to more environmentally friendly filter materials are undermined if butts containing the toxic materials filtered from tobacco smoke are thrown away thoughtlessly, allowing those materials to leach out.

Legislation is one of the other issues driving change, and it must be said that there are few factors as powerful as new laws in ensuring change takes place within a reasonable time. Zisov told me that the recycling costs associated with cigarette butts containing plastic materials comprised one of the main factors that drove filter and cigarette manufacturers to look for more environmentally friendly filter materials. Currently, the amount that had to be paid to companies that recycled such butts was increasing each year, and, recently, those costs had doubled in Bulgaria.

That was one of the reasons why there was currently a lot of interest in cigarette filters formed from crimped paper, Zisov said. The filtration properties of crimped paper were not as good as those of acetate tow, but they were being improved.

New opportunities

While the challenges posed by complying with new cigarette and filter regulations are considerable, these regulations also present opportunities. Zisov said that while the annual, global demand for the filters supplied by specialist manufacturers was currently falling, Yuri Gagarin’s volumes during the past four years had been stable and were expected to remain stable in the foreseeable future. In part, the reason for this optimism was that the company had dramatically increased its product portfolio during the recent past so while demand for its monoacetate offerings had fallen, this fall had been more than offset by increased demand for complex filters, such as hollow and dual charcoal products.

Another reason is that as cigarettes become more expensive year on year, interest in RYO cigarettes grows and with it demand for RYO filters. And while it was true that, since price was the main driver of the RYO market, demand for special RYO filters was still relatively low, interest in different specification filters was increasing tremendously in some markets, said Zisov. The suppliers of these filters to the retail market were looking for varying segment diameters, lengths and hardness along with, for instance, flavor and charcoal applications.

Of course, the existence of such diversity within what is still a relatively small volume plays into the hands of specialist filter manufacturers. Meeting such a demand takes a lot of resources and requires a skilled workforce, so the suppliers to the retail market are drawn to using specialist suppliers and thus avoiding the fixed costs of manufacturing. There is a downside to this, however, because it implies considerable investments in new technology and knowhow for the specialist filter manufacturer, and, given that such investment is being made at a time when volumes are merely stable, profits are likely to be squeezed.

While not ignoring the fact that the traditional cigarette industry has been under pressure for many years and will continue to decline, Essentra, too, sees opportunities. It predicts, for instance, an increase in demand for slimmer cigarettes and, therefore, slimmer filters in Africa with the uptake there of smoking among increasing numbers of women. In other markets such as China and South Korea, Essentra has identified an increasing demand for innovative new flavors, a demand that called out for “exotic flavored filters to cater to those evolving taste profiles.”

At the same time, demand for super slims and shaped filters was growing in China, and tobacco manufacturers were using more specialized filters to provide differentiation within their premium ranges and unique smoking experiences for their consumers.

Meanwhile, as smoking regulations become stricter around the world, opportunities were arising in respect of heated-tobacco products. “Tobacco-heated products are also becoming increasingly popular,” said SK, “with the current pandemic situation accelerating the switch from traditional smoking as consumers become increasingly health conscious. With such a potential growth opportunity available in this segment of the market, we have also invested our innovations efforts into filters that can cater to tobacco-heated products.”