Reducing waste and saving energy in manufacturing boosts revenues, improves customer satisfaction and reduces environmental damage.

By George Gay

Filter cigarettes and the hinge-lid packs in which, on many markets, most cigarettes are sold have been available in similar forms for 60 years to 70 years, and, during that time, their manufacture has been guided by increasingly specialized materials suppliers, brand owners and machinery builders that have become environmentally aware, commercially astute and technically advanced. So, on being asked to write a story looking at what tobacco machinery suppliers are doing to reduce the usage of energy and the creation of waste during the operation of their machines by tobacco manufacturers, my first thought was that perhaps, after so many years of development, there wasn’t much more that could be achieved.

I needn’t have been concerned. While the central objects of the exercise, the cigarette and pack, remain, to the uninitiated at least, much the same, the focus and interests of machinery suppliers have broadened to take in everything from how their employees get from home to work through production materials to the new industrial revolution. There is even a focus by one company on the efficiencies of factories that might or might not use its machinery.

Nurturing a Mindset

But what about the bit concerning how your employees get from home to work? How does that fit into the grand scheme of things? I hear you ask. Well, according to Courtland Macduff, Aiger’s sales director for Asia, this has to do with the idea that if you are going to improve the operational efficiencies of the equipment you offer in respect of such things as energy usage and waste, you need to build such thinking into the ethos of the company. Aiger had set up, for instance, a carpool system that allows its employees to get to work using less gasoline and creating fewer carbon dioxide (CO2) emissions than they would if they all traveled alone. Four years ago, the company introduced efficient waste management systems to deal with everything from machining waste to general consumables. And, on a larger scale, it recently installed a 350 MW solar power system on the roof of a new manufacturing bay, allowing it to function as a smart factory in which heating and lighting are based on zone scheduling, a system that has provided for a 20 percent saving in energy costs.

As Macduff said during an email exchange, saving energy and reducing waste worked by example, so now, every design engineer was focused on smart solutions aimed at providing better machine performance because the faster a manufacturer was able to operate with the highest uptime, the less waste was generated. But this had to involve a joint effort. Machinery manufacturers could have only a limited impact on operational waste if factories didn’t maintain high efficiencies by optimizing their procedures and materials.

But no operation could be perfect, so, at the same time, Aiger machinery “digested” rejects as far as possible by recycling tobacco shorts and reclaiming the tobacco. End-of-bobbin machine production wastage had been reduced as had glue application.

In reducing energy usage, designers were, for instance, working on the optimization of drive selections and had already minimized the power consumption of heating elements by using a higher level of temperature control and new insulation materials to protect the areas heated to high temperatures, which was one of the major power drains. At the same time, designers were constantly looking to incorporate new technologies.

In this regard, Macduff made the interesting comment that while new technologies were welcome, they came at a price, so they had to be introduced at the right time and for the right reasons. Tobacco companies would not pay more simply to have a machine that used less energy. Output mattered at the end of the day, and high efficiency was not negotiable.

There was something of a trade-off to be made here. While modern machinery was generally faster and more reliable and consistently produced better quality products than was the case in the past, such improvements did not necessarily lend themselves to energy savings because the newer machinery used more controls, more automation and more drives.

But there are other areas where savings of one type or another can be made, often working in conjunction with materials suppliers and tobacco manufacturers. Factory floor layouts could be optimized, said Macduff; optical fibers could replace cables; new, harder-wearing materials could ensure that parts had longer lives; and the 3D printing of parts at customer sites could cut the impact of transporting such materials. Coreless bobbins could be introduced, filters and packaging materials that are more environmentally friendly could be brought in and the use of plastics could be reduced in respect of packaging materials for tobacco products and even machinery exports.

Finally, Macduff said Aiger was one of the leaders in machinery manufacturing flexibility, and the modular concepts engineered into its machinery helped to keep efficiencies high in the face of brand changes, which always created a degree of startup waste.

Win, Win, Win

Meanwhile, Montrade’s senior sales manager, Emanuele Massari, said his company’s machines were designed so as to map product flow because the focus was on maximizing product quality while minimizing material consumption and waste. The company had a division dedicated to the research and development of sensor and process control systems that, once integrated into its machines or even those of other companies, enhanced productivity optimally. “It is an essential step of the migration toward industry 4.0,” he said- in what I took to be a reference to the sorts of new processes that focus on interconnectivity, automation and machine learning.

Artificial intelligence provided all Montrade’s sensors with auto-learning skills, so systems improved themselves autonomously, he said. And such autonomous maintenance initiatives helped provide for an increase in machinery MTBFs (mean time between failures), which, in turn, led to “a righteous path of real sustainability.” “This synergy allows us to optimize and reduce the material and energy consumption and the waste of spare parts,” said Massari.

Sustainability was said to be one of the main drivers at Montrade because working to reduce waste and save energy created what Massari described as a “win-win-win virtuous loop.” The first win was that customers could use Montrade’s equipment to manufacture more high-quality products while spending less, thus increasing their revenues and consumer satisfaction. The second win saw Montrade’s business boosted because its customers were satisfied. And the third win meant that the environment and, consequently, the global community profited from the reduced impact of the tobacco industry.

Massari said that his company’s machines were designed to constantly monitor the consumption of utilities with an eye on reducing usage. The levels of electrical consumption and compressed airflow rates, etc., were always available to view on human-machine interfaces, which was a standard feature not an optional one.

Another issue on which Montrade had been focusing its sustainability efforts concerned the materials used on its machines. The company collaborated closely with its customers and with materials suppliers to rethink the product as more eco-friendly and more fit for the final consumer. Recent examples of this approach could be seen in the company’s machines for producing biodegradable cigarette filters and paper tubes. A unique crimping technology allowed conventional acetate filters to be replaced with paper ones while reducing by about 20 percent the paper consumption typical of other machines available on the market.

As well as offering new filter-making equipment, Montrade also revamps older equipment to produce eco-friendly products. “For instance, we offer our paper crimper in a free-standing configuration to retrofit existing filter makers to convert them to make plastic-free filters,” said Massari. “In the same way, we have also recently developed a wide range of conversion kits for existing packing machines to reduce the wrapping materials and/or replace them with plastic-free ones.”

The Holistic View

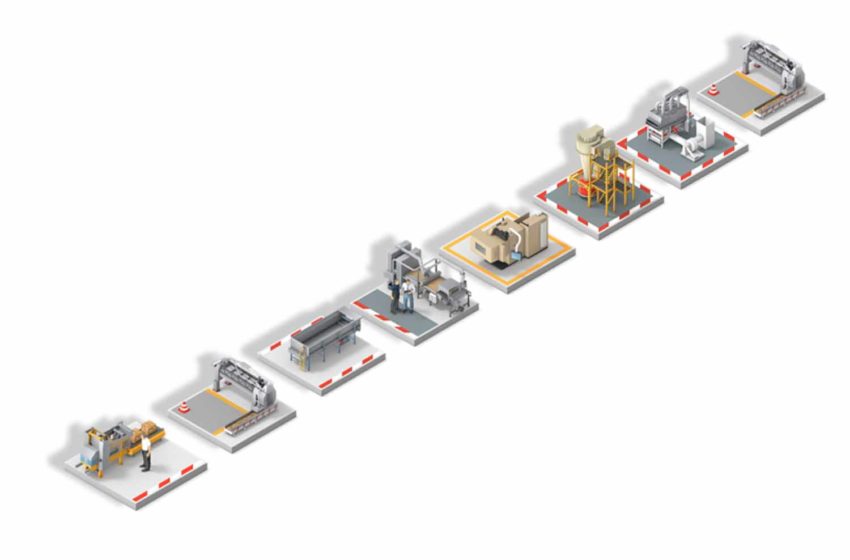

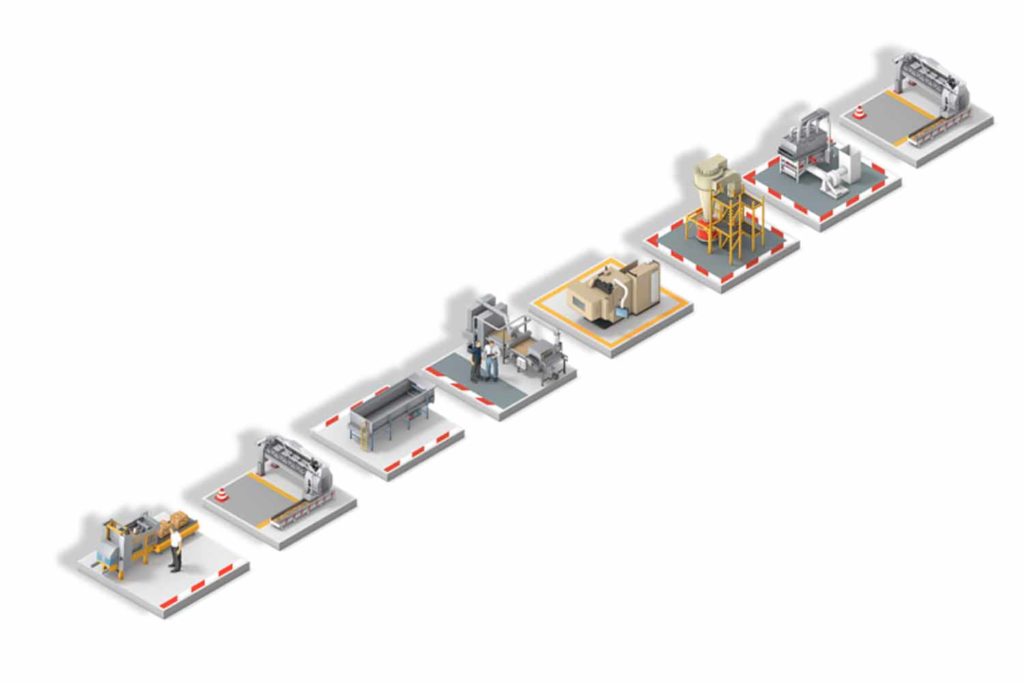

Another way of looking at reducing waste is to examine just tobacco waste but over complete operations. Marco Castro, global head of Hauni Advanced Services (formerly Hauni Consulting), said that while the whole tobacco industry was currently working on reducing waste, his division had, in July 2020, set itself the ambitious challenge of approaching this objective in a different way. And, in doing so, it had pioneered a completely original approach, tobacco waste prevention (TWP), by developing an integrated methodology for preventing waste at critical points in green leaf threshing plants (GLTs) and during primary processing and secondary manufacture.

Interestingly, TWP can be applied to all production facilities regardless of the machine base. “Our approach is strictly based on the existing conditions of our customers’ brands,” said Castro in announcing the initiative. “This enables them to prevent waste quickly and successfully, maintaining these gains over the long term.”

TWP is said to offer immediate, measurable improvements, and figures said to have been achieved already in customer projects are impressive: The reduction of waste generation in GLT processes is up to 50 percent, in the primary it’s up to 70 percent and in the secondary up to 60 percent.

“The first step is to quantify the potential for waste prevention at the customer’s site,” said Castro. “This is the basis on which we implement our TWP methodology, which aims to achieve the physical limits for waste prevention for the respective combination of blends, brands and equipment as quickly as possible.”

The approaches adopted as part of TWP are said not only to prevent waste but also to reduce production complexity and technical costs by standardizing blend/brand and equipment combinations where they are relevant to waste.

The starting point for every TWP project is the manufacturer’s own production facility. “This means that we not only strictly consider their specific blends and brands but also implement the TWP specifically for their existing production equipment,” said Castro. “No investments in equipment are necessary to achieve this new, optimized level of waste and costs—at least initially. Of course, on request, we can advise our customers on the potential of machine upgrades or other changes to their equipment while focusing on waste prevention.”

What might well appeal to tobacco manufacturers is that the price of implementing TWP is performance-based, something that Hauni says underlines its belief in its new service. “We are certain that we can deliver the savings we promise our customers after quantifying the waste situation,” said Castro. “That is why payment for this service is performance-based. If we achieve less than we promise, the price is reduced. If the improvement falls below a set level, our clients pay nothing.”