There are multiple ways to heat tobacco without burning it.

By Stefanie Rossel

With the multinationals dominating the global market for heated-tobacco products (HTPs), one could easily think there are only two heating solutions—resistive heating with a blade or pin and induction heating. For years, Philip Morris International, which established a whole new category with its IQOS device, had been working on a third method—carbon heating of tobacco—but the company has since discontinued this platform. Recently, however, more heating solutions have entered the market. In their quest to optimize the user experience, independent manufacturers have resorted to other heating technologies.

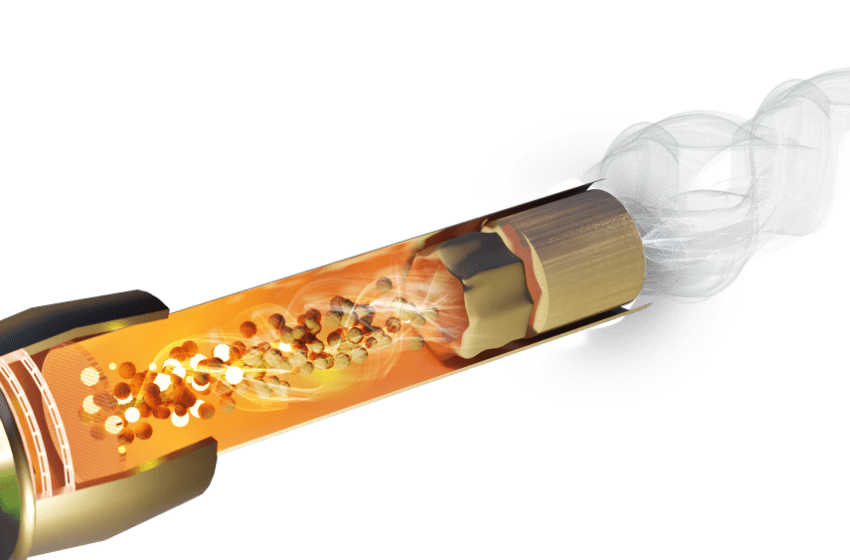

At the InterTabac trade fair, which took place in Dortmund, Germany, in late September, HNB Center of the Netherlands presented its MC Cosmic consumable. The associated device is powered by airflow technology. Also known as convection heating, it generates a stream of hot (350 degrees Celsius) air that flows through the heating chamber, surrounding a consumable that is filled with loose tobacco granules instead of a tobacco plug. A membrane at the end of the heat stick prevents the granules from falling out and contaminating the device.

The granule-filled sticks are the first of their kind, says Gert Gorter, head of export at HNB Center. “The granules consist of 100 percent tobacco derived from tobacco leaves. Together with the heating device, the taste experience is very good.” The airflow technology, he adds, heats the stick more effectively and evenly than a pin, which tends to heat the tobacco immediately surrounding it to higher temperatures than leaf at a greater distance.

We cannot add any flavors, but we can play with different sorts of tobacco and blends as well as with the number of grams of the granules in the stick.

Gert Gorter, head of export, HNB Center

More Like Smoking

A subsidiary of VCT International, HNB Center began to work with granule-filled consumables provided by Yunnan Tobacco, which holds the patents for the sticks and corresponding device, almost two years ago, first trying them on a traditional device. “The taste was already better,” says Gorter. “You can smoke the sticks with a blade device, but this of course will perforate the membrane and create waste. We didn’t want that, so we thought of using airflow.” While airflow has been around for some time, the technology has improved considerably in recent years, according to Gorter.

Gorter believes that airflow-heated granule-filled sticks provide consumers with an experience that is closer to traditional smoking than other systems. “Two years ago, we did a survey with smokers on our traditional heat sticks and included two packs of the granule-filled prototypes,” he recalls. “These instantly went to No. 1 in the perception of the participating consumers. The taste is fuller. It’s also our answer to the flavor ban on HTPs, which will be effective in the European Union from May 2024, allowing only tobacco flavor. We want to provide a heat stick that comes close to traditional tobacco smoking. We cannot add any flavors, but we can play with different sorts of tobacco and blends as well as with the number of grams of the granules in the stick; a higher grammage will result in fuller flavor.”

The device, which is called My Choice NOVA, has a battery capacity of 15 sticks, making it suitable for the average smoker, who typically consumes 13 cigarettes a day. Gorter is convinced that his technology will make a significant change. “You can also put any stick in this device; the whole system of airflow is giving you a better smoke experience.”

The company started its business in 2019, when it obtained the European distribution rights for the heat sticks from Yunnan Tobacco. HNB Center created the brands, designed the packaging and developed a marketing narrative. “At that time, PMI was the only HTP manufacturer in the European market,” says Gorter. “In 2019, we launched MC, which is the heat stick brand, and My Choice, which is the device. We started with traditional heat sticks similar to PMI’s Heets. What makes us different in this market dominated by the big four is that we work with independent players—distributors, wholesalers and agents who do the sales and marketing in the countries where we are present.”

Currently, the company sells its products in seven countries, including Italy—Europe’s largest HTP market—Portugal, Spain and some Eastern European countries, and it aims to expand into new markets.

Due to the flavor ban, Gorter expects the entire EU HTP market, where flavored heat sticks account for 70 percent of sales, to change. Flavored sticks also represent a big share of HNB Center’s business. The company is betting that its tobacco-flavored granule-based consumables will help offset declining sales of flavored products following the EU ban.

HNB Center plans to launch its MC Cosmic consumables and device in several countries, starting in Italy, where HTP consumption currently stands at 6 billion sticks annually.

Fast and Precise

Meanwhile, in Switzerland, NVX Labs is developing an HTP device using radio frequency (RF) technology. The concept is similar to that of a microwave oven: A radio frequency generator generates an alternating electromagnetic field within a cavity that holds the consumable. The tobacco plug inside the consumable comprises primarily tobacco and flavor, especially VG, PG and water molecules.

These molecules absorb the radio frequency energy at a frequency of 2.45 GHz. Their inherent dielectric loss properties cause them to rotate and align with the oscillating field’s opposite pole, similar to how a bar magnet behaves in a fluctuating magnetic field. The molecular movement in turn generates heat.

NVX Labs’ technology allows for contactless, precise heating of the tobacco plug and distinct flavor profiles, according to Ralf Dumler, founder and chairman of NVX Labs. It also effectively manages the release of nicotine. “The flexibility of the radio frequency energy, adjustable within milliseconds, guarantees exceptional precision in heating the tobacco plug and aerosol release,” he says. “This technology eliminates the need for any metal pieces, metal foils or a heating blade within the tobacco plug, signifying a major advancement toward sustainability in line with the U.N. 2030 agenda for sustainable development.”

The device operates within the ISM band, a universally accessible frequency range that doesn’t require users to obtain a license. Upon activation, the device prepares the consumable within 4 seconds to 5 seconds for the first puff. What’s more, the technology can achieve equivalent aerosol production at temperatures below 210 degrees Celsius.

“Thanks to our technology, tobacco companies can now develop a consumable similar to PMI’s Terea, with a closed end of the tobacco plug but without the need for a metal component inside the tobacco plug,” says Dumler. “In our latest product developments, we’ve harnessed the power of cutting-edge materials science to eliminate the need for traditional tobacco or reconstituted tobacco in the tobacco plug or filling. This sustainable approach not only promotes an eco-friendlier solution but also enhances aroma and provides an elevated consumer experience—all without relying on substrates derived from the tobacco plant.”

Apt for Medical Use

Initially collaborating with a multinational pharmaceutical company, NVX Labs is the pioneering patent holder for RF HTP technology, according to Dumler. The intellectual property provides protection beyond reduced-risk products to both medical and recreational cannabis applications.

Furthermore, the device can function as a conventional pharmaceutical inhaler tailored for the pharmaceutical industry.

A chemist by training with a strong background in the pharmaceutical industry, Dumler had previously ventured into RF heating through his initial startup company. The inspiration to use the technology for HTPs, he says, was a natural progression.

NVX Labs first crafted a handheld prototype demonstrating the feasibility of RF heating for commercially available HTP consumables. Additionally, the company offers its own commercially available evaluation and testing device, enabling tobacco companies to assess RF heating technology and develop their own RF heating products.

Alberto Torreno, co-founder and managing partner of NVX Labs, is optimistic about advancing his HTP device to the preproduction phase within approximately 18 months. He believes that the vast HTP market might intrigue the semiconductor industry because his device relies on GaN and LDMOS solid-state semiconductors.

Simultaneously, NVX Labs is developing a pharmaceutical product, a thermal metered-dose inhaler. The company is researching the potential of this inhaler for administering Salvinorin A, a compound that has shown promise for addressing treatment-resistant depression and substance use disorders.

Although Salvinorin A has yet to be approved by the U.S. Food and Drug Administration or the European Medicines Agency, Dumler proactively included its potential applications in his patent. “Our pulmonary drug delivery device offers the unique benefit of heating a drug product with pinpoint accuracy and without excipients, which enables new applications of drug delivery within the pharmaceutical industry,” he says.

A Ray of Light

Sixhill, the HTP division of First Union Technology of Shenzhen, China, presented several devices using its Breelight heating technology at InterTabac. According to Sixhill, Breelight is the first infrared heating technology for tobacco. The company says it can effectively stimulate the release of tobacco aroma and nicotine due to the absorption peak characteristics of different flavors, thus achieving unique flavor styles.

In this technology, infrared radiation travels through air or space until it hits an absorbing surface where it is partially converted to heat and partially reflected. But rather than warming the ambient air, this heat warms its object directly.

Used in an HTP, Sixhill says, the technology heats tobacco more evenly and efficiently, improving the utilization rate of a stick to 90 percent. According to the company, IR heating improves the aroma quality, intensity and sustainability of tobacco. It also releases nicotine more effectively than other technologies.

Sixhill’s Aurr device reportedly has a nicotine release rate of 95 percent and a nicotine transfer rate of 45 percent.