A small family business, LTL holds its own as a supplier of equipment to the global tobacco industry.

By George Gay

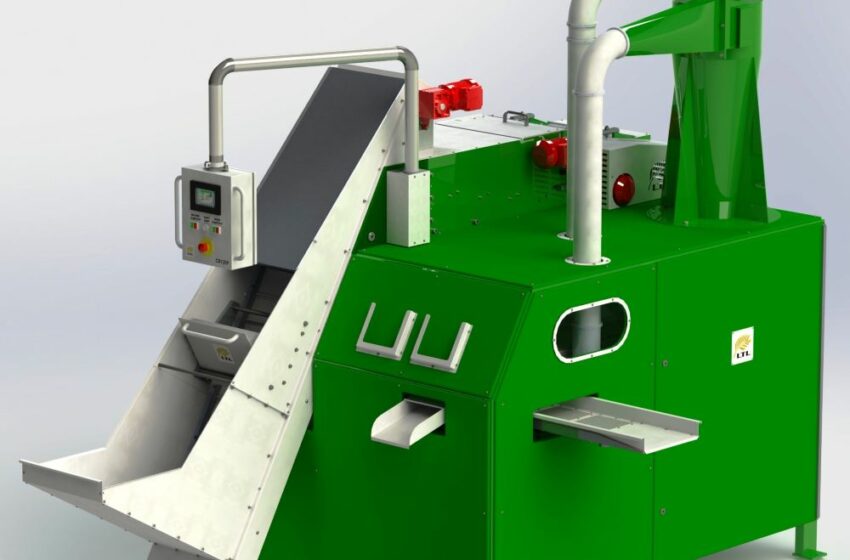

While I was corresponding in March with the founder of LTL, Paul Lawton-Bryant, he was involved hands-on with others in his company fulfilling an order for one of its CR120P super-slim format cigarette-tobacco reclaim systems (CTRS). I mention this because LTL is very much a family company, and when asked what its strengths were, Lawton-Bryant said at the end of his reply that one of them was down to his personal drive for perfection in everything he did.

“I am very hands on in the business and spend many hours in our workshop machining parts and building the machines to ensure that the high quality I demand is maintained,” he added. And the point is that I could see this quest for perfection from another angle. Although heavily involved in the new CTRS project, he took the time to answer with precision and clarity every one of a long list of questions that I had sent to him. And he answered frankly: He even made the point that his drive for perfection could also be seen as a weakness.

LTL is owned privately by Lawton-Bryant and his wife, Julie, who is the financial director. They started trading in 1997, though the company, as currently constituted, was founded in 2001. It operates out of premises in the village of Chilbolton,* Hampshire, U.K., where it designs and manufactures primary processing equipment for the global tobacco industry, though, in recent years, it has supplied mainly CTRSes, tobacco feed systems and central dust collection systems. It is involved, too, in nontobacco-related projects, but its core business is focused on tobacco-related products and services.

Quality of Output

The CR120P, which is LTL’s most in-demand reclaim system, and the higher-capacity CR250P are characterized by their high levels of efficiencies and relatively low running costs. “Our systems regularly achieve in excess of 96 percent reuseable reclaimed tobacco yield,” Lawton-Bryant told me in an email exchange. “Energy consumption is quite low, with a total electrical load of 4.2 kW and compressed air usage of just 3.0 cfm for the CR120P and a little higher on the CR250P. In addition to this, the machines use very few consumable spare parts and come with an industry-leading two-year warranty based upon single-shift operation.”

LTL’s reclaim systems are 99 percent standard, though there are different versions for regular and slim cigarettes, and the company will supply units to feed rejected cigarettes into the CTRSes if required. Otherwise, the main customizations take in the usual elements such as supply voltages/frequency and paint color. The CR250P was launched about 10 years ago in response to several inquiries for larger capacity machines and a general trend among competitor companies. However, generally, LTL’s customers still prefer the flexibility of having a smaller capacity machine—running two or more for different blends rather than having one larger-capacity machine.

The focus in developing the CR range of reclaim systems has been on the quality of the output product because, Lawton-Bryant said, once a cigarette had reached the stage where its tobacco needed to be reclaimed, that tobacco was probably at its most fragile and at its most valuable, having been conditioned, blended, cut, expanded, dried and flavored. “The particle size and moisture content of the tobacco within a cigarette means that the tobacco could easily be degraded through unsophisticated mechanical handling and separation processes, and it is in those areas that we have focused our design to minimize damage and maximize yield,” he added.

Return on Investment

The potential monetary savings inherent in efficiently reclaiming processed tobacco that would otherwise become a costly burden would seem to make an indisputable case for CTRSes, but I wondered whether there were other factors in play. In answer to a question about whether tobacco industry ESG (environmental, social and governance) policies had been driving demand for CTRSes, Lawton-Bryant said that such policies would be a consideration in purchasing decisions but that he did not see them as driving demand.

The key drivers in any business had always been and would continue to be the need to make a return on investment. A cigarette was at its most valuable having gone through the full primary process, he said, a fact often given less consideration than it deserved, so any damage and loss occurred at that point in the process would be the costliest that it could be. This fact alone often helped justify the relatively small investment required to purchase a good-quality CTRS, though actual payback periods would vary drastically depending upon individual circumstances.

For example, in the past, LTL had sold a machine to a customer that previously disposed of all its reject cigarettes, which was said to have made the payback very short indeed. “A more usual scenario would be the savings our particular machine can make when compared to a competitor’s machine,” Lawton-Bryant said. “We have seen reuseable tobacco yields as low as 70 percent in other machines available in the market, so with our machine regularly achieving 96 percent yields, a 26 percent increase could mean payback within 12 months.”

Global Reach

LTL supplies machines to a wide range of customers around the world, though, recently, the Middle East and Africa in particular have provided good opportunities. In fact, the project mentioned at the start of this story involved the supply of a CR120P to a customer in the Middle East that is planning to buy a second machine following the installation of the first one. “We are very fortunate in that we have several repeat customers,” said Lawton-Bryant, “and I feel this is one of the best references we could possibly provide.”

At the same time, LTL supplies machines to companies both large and small, though most of its customers tend to be those operating smaller manufacturing facilities with between one and 10 makers. In fact, Lawton-Bryant said that LTL was probably an unusually small-scale company among those supplying equipment to the global tobacco industry and that it was understandable that this could be seen by some customers as a risk. “However, I do feel that our long history of supplying high-quality and innovative equipment to the global tobacco industry proves our commitment to the industry and should provide some assurances,” he added.

This takes us back once again to the start of the story because, clearly, small, family-run businesses offer several advantages. “I think it is our small size which allows us to react quickly and effectively to new challenges and changing customer demands,” said Lawton-Bryant. “A good example of this was our reaction to the recent global pandemic where travel restrictions were imposed. This had a massive impact upon our ability to install and commission equipment, so our team focused upon a remote commissioning solution, which included fitting a router and camera to machines, thereby allowing us to remotely access the PLC, guide the customers on installation, remotely commission the machines and view the product results through the camera.

“Our core team has over 160 years of experience in the industry covering both mechanical and electrical/software engineering and process knowledge, which meant that the new system was conceived, designed and implemented within a matter of weeks, and not one of our customers suffered through our inability to travel to site throughout the restrictions. This remote access remains a feature of the CR range of reclaim systems today and can assist with ongoing support and training if required.”

Enduring Resilience

In fact, it is clear that Lawton-Bryant sees the advantages of running a small-scale operation as outweighing the potential pitfalls of trying to grow the business. “Over almost 30 years of running my own business, I have resisted the pressures to grow into a large company,” he said. “I wish to serve the niche industry that we are in to the very best of our ability, and that requires a very tight level of control throughout the business processes, something which can easily be lost in a larger company.”

When I asked how confident he was about the future of the tobacco industry and, especially, the cigarette industry, that part of the industry LTL mainly served, he was frank in his reply. “For more than 20 years now, I have had regular periods of concern over the sustainability of our business in the tobacco sector, though I am happy to say that so far those fears have been relatively unfounded,” he said. “Of course, the industry has faced several challenges and continues to do so, but generally, it is very resilient.”

And finally, I asked how confident Lawton-Bryant was about LTL’s future. “I am confident that we can respond to the many challenges that running a business encounters,” he said. “Whether that remains mostly in the tobacco industry remains to be seen, but I sincerely hope that it does,” he said.

*Although “only” a village, Chilbolton, too, punches above its weight with an observatory that boasts facilities and expertise in atmospheric science, satellite tracking, radio astronomy and communications that support U.K. academia and industry.