The challenge of squaring public health with government revenue objectives

By George Gay

I think that I should declare an interest. It has to be said that I am not an objective observer when it comes to taxation. I tend to the view of the 19th century French economist Frédérick Bastiat, who apparently defined taxation as state-sanctioned plunder. Don’t get me wrong—I am quite prepared to admit that governments have to indulge in a little plundering. I just wish they would be more open about it.

In the normal way of things, marauders storm ashore, sack part of your village and plunder much of what isn’t nailed down, but they leave enough standing to allow regeneration—so there will be something to plunder when they return. And, to be fair, governments largely follow the marauders’ code on plunder. They take just enough to render their victims too weak to protest but strong enough to continue indulging in all of those pursuits that are taxable—every pursuit you can think of, that is.

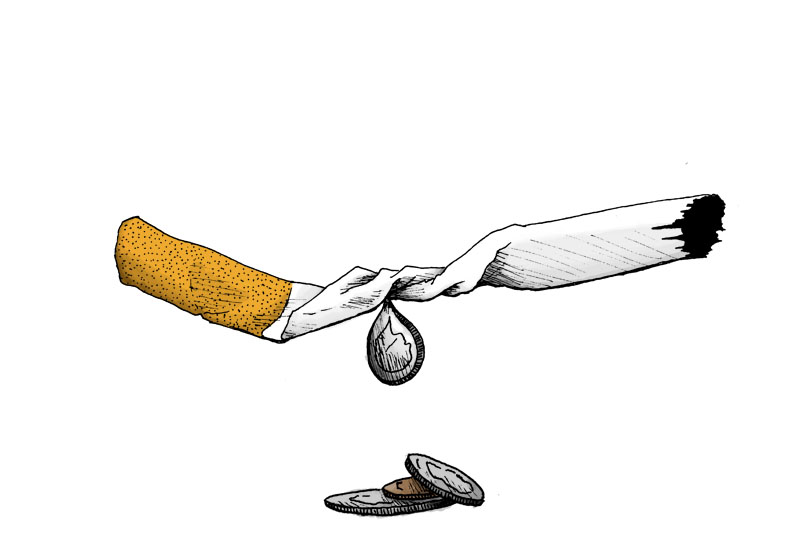

Tobacco taxation is a different matter, however, because here governments have been plugging the idea that their policies constitute a moral crusade, and there is nothing so crushingly pitiless as a moral crusade. In this case, the marauders’ code can be consigned to the flames because governments are increasing taxes on tobacco not to fill the holes left in their coffers by profligate spending, you understand, but because they want to help the very people they are taxing. It almost brings a tear to your eye.

But not quite. There’s something odd about this moral crusade. The line we are fed is that taxation is raised to the point where people can no longer afford to consume tobacco products, and, because consuming tobacco is bad for them, their not being able to do so must offer a benefit. Under a system of “tax to the max,” the sinners are saved and proudly take their places behind the gleaming banner of health and vitality.

Assumptions

The first thing that has to be said about this nonsense is rather obvious but is nevertheless worth saying. This tax to the max policy is based on the view that one group of people know best and must be allowed to impose the totality of their beliefs on another group; it is, after all, a crusade. And it seems to stand no matter how much evidence comes to light to question these beliefs.

Following on from that, a few people, I think, would agree with me that the decision to launch such crusades are made with those in the vanguard having exaggerated the negative aspects of tobacco consumption—sometimes grossly so—and ignored the positive aspects of it. And more than a few people would agree that the crusade is launched on the assumption that—against all the evidence put forward by the crusaders themselves—tobacco consumers are able to give up these products.

One common riposte to this last criticism has it that addicted consumers who are no longer able to afford to buy tobacco products can avail themselves of quit products, sometimes at no direct cost to them, though the success and failure rates of these quit products are normally not mentioned.

But this is not quite right. The evidence coming out of Japan at the moment would tend to indicate that these products are not always around when they’re needed. Writing in The New York Times last month, Hiroko Tabuchi described how Japanese health professionals and many of the nation’s smokers were grumbling because, three months after the imposition of a massive tax rise on cigarettes, it was still difficult to get supplies of Pfizer’s quit-smoking drug Chantix.

I don’t think that you have to be a cynic to wonder why, given that one of the stated aims of the tax hike had been to get people to quit, the government did not work with the providers of quit products to ensure adequate supplies; or am I expecting too much?

Still; the shortages might have been a mixed blessing for some. On the same day as the Tabuchi story, Kent Faulk was describing in The Birmingham Post how nationwide in the U.S. 1,200 lawsuits were being brought against Pfizer in relation to Chantix. Smokers and their families allege that Chantix left would-be quitters with a variety of psychological problems, allegations that Pfizer denies.

Bankrupt crusade

One thing that is certain is that the outcome of the moral crusade isn’t guaranteed; otherwise, given the figures often quoted for the number of people who “want” to quit tobacco, it would be easy for a government to put the taxation on tobacco products up by a million percent, hand out quit aids and watch the massed ranks of crusaders lead all of the former tobacco users into the promised land.

So what is wrong here? Well, just about everything, but I want to look at only a couple of issues. Firstly, if you want to examine how bankrupt is the moral crusade that is built upon the policy of tax to the max, you need look no further than Canada, though what has happened there has happened in some other countries also, to a greater or lesser extent. Canada’s tobacco taxation policies have encouraged the illicit trade to such an extent that, overall, this trade now accounts for about one-third of the market. In one province, it accounts for nearly 50 percent of cigarette sales.

The general response to this situation is not to reduce tobacco taxation but to try to increase enforcement and, presumably, in the process, criminalize rising numbers of people. You have to wonder at what point the authorities will admit that the volume of illicit sales indicates that a significant minority of the country’s population believes that tax to the max policies are unfair. At what point will they wonder if these people haven’t got a case? At what point will they ask themselves whether putting more and more people on the wrong side of the law truly represents a moral crusade? At what point will they be moved to reconsider what sort of a society they want to foster?

I fear it will be a long time. This is not the first time in recent memory that Canada has found itself in a similar situation. And, coincidentally, as I was writing this piece, Imperial Tobacco Canada issued a press note lamenting the Minister of Health’s decision to abandon her commitment to tackle the nation’s contraband.

The press note said that the Royal Canadian Mounted Police had reported recently that there were now 50 illegal cigarette factories and more than 300 smoke shacks selling tobacco on First Nations reserves in Canada.

After announcing in September that tackling illegal tobacco was her priority, the note said, special-interest anti-tobacco groups, most of them funded by her own department, lobbied the minister heavily to focus on increasing the size of health warnings on legal products.

“Three months ago, the minister of health said illegal tobacco was her priority,” said a clearly frustrated John Clayton, who is vice president for corporate affairs at Imperial. “However, she has done nothing to crack down on the illegal trade since then. Instead, she caved in to the pressure of a handful of anti-tobacco groups.”

Questions

At first sight, the phrase “tax to the max” looks straightforward enough, but stare at it for long enough and a number of questions start to arise. Two obvious questions are: What is the max and who determines what is the max? But, to me, the most interesting question is, what is tax? In the EU and elsewhere, tobacco consumers are being forced to pay hundreds of millions of euros to fund various initiatives to combat the illicit trade in tobacco. I’m not sure what this money is called by those who receive it—whether it is referred to as a penalty, fee, contribution, bonanza, lottery prize or whatever—but, basically, it is a stealth tax levied on the consumers of licit products that is handed over to various agencies to fund seemingly predictably unsuccessful attempts to reduce the illicit trade in tobacco that is a direct result of the price of cigarettes being too high. Is this rational? Is this fair? Is this all part of the moral crusade? To me it looks like a dog chasing its tail.

Meanwhile, in the U.S., most consumers of licit products are made to make payments—through the manufacturers of the products they consume—under the Master Settlement Agreement (MSA), though, as far as my memory serves me, no tobacco consumer ever agreed to making such donations. Again, this is put forward as being part of some moral crusade, but it is far from that. The agreement is spun as being a punishment on the tobacco manufacturers, but, again, it is not; it is a tax on tobacco consumers. And it wouldn’t be so bad if all or at least most of the money raised from this tax went to fund tobacco control programs, as you might rightly expect, but it does not.

By the way, if you aren’t convinced that MSA payments are just taxes by another name, you would do well to check out what is going on in Texas at the moment. According to a story by Gary Scharrer for the online version of The Houston Chronicle, Texas is one of two states (the other being Florida) that are parties to the MSA but that don’t require companies that were not signatories to the agreement to participate in it.

But Texas has a problem: a budget deficit of more than $20 billion, according to recent estimates; so Altria has suggested that part of this hole could be plugged by drawing the non-participating companies into the “agreement.”

Here is what Scharrer quoted Justin Phillips, a spokesman for Global Trading, a small tobacco wholesaler based in Enid, Oklahoma, USA, as saying: “The big tobacco companies are trying to shift the market share to their favor by placing a tax [my emphasis] on smaller companies that were not involved in the (late 1990s) settlement.”

As is hinted at above, the max in tax to the max cannot be limitless. The max is simply the level that allows governments to wheedle as much money out of tobacco consumers as they possibly can, but it involves a difficult calculation. Governments have to be on their guard that they don’t overstep the line of diminishing returns—the point at which the theoretical increase in revenue from increased taxes is wiped out by people refusing to buy tax-paid products. So what this means is that in those jurisdictions where tobacco tax is purportedly increased to the max to try to stop people smoking tobacco, tax levels are largely determined by the strength of the illicit trade. The moral crusade is being led by gangs of criminals. Quite.

Bailouts

At this point and somewhat uncharacteristically, I’d like to take a diversion to examine what seems to me to be an inconsistency in many governments’ taxation policies. As is described above, these governments say they increase the taxation that has to be paid by the consumers of tobacco products because those consumers are addicted to a product that has a negative effect on the health of society. The thrust of these increases is aimed at breaking the bonds of this addiction and thereby increasing the health of the community.

The trouble here is that there is at least one other group of people who may be closely equated with tobacco consumers but who are treated in a completely different way. I’m talking, of course, about a certain class of banker. These bankers are addicted to a product that—as has been proved beyond any question in the recent past—has a negative effect on the health of society. But the reaction of governments in this case is not to try to break the bankers’ addiction to greed but to feed it. Although governments wouldn’t dream of handing tobacco products to nicotine addicts, they seem not to think twice about throwing money at those addicted to greed.

Why is there this divergence of approach? It’s difficult to say, but the only real difference that I can see between the tobacco users and the bankers is that the former are, in the main, relatively poor financially and therefore powerless, while the latter are relatively rich financially and therefore powerful.

Ireland is one country where smokers have been pilloried and taxed to the max and beyond, and where the bankers have failed comprehensively; so in the normal way of things, the former are helping to bail out the latter. I have written elsewhere in this issue about Ireland, but the story from that country is so monumental that it bears repeating. At the end of last year, the Minister of State for Health, Áine Brady, told the Dáil that currently 29 percent of the population smoked despite a ban on tobacco smoking in public places, the abolition of packs of fewer than 20 cigarettes, the ending of in-store displays and advertising, and the retail price of cigarettes being, at €8.55 ($11.06) a pack, “the highest in the world.” In 2004, 27 percent of the population smoked.

Clearly, not only does the tax to the max crusade against tobacco fail the test of morality, it fails the test of efficacy. It is a failure, but that won’t make any difference. Most governments seem not to be concerned about such failures.

At this point, it would be interesting to turn the focus to Japan, where, normally, they seem to take an orderly approach to things, including tobacco taxation. Well, that was the case until last year when, in the run-up to an unprecedented tax increase on Oct. 1, which, together with a manufacturer’s increase by Japan Tobacco, raised the retail prices of some brands by 40 percent, the market was thrown into chaos.

In September, cigarette sales, at 37.4 billion, were up by 88 percent on those of September 2009, due to a last-minute rush ahead of the excise increase. But sales were said to be down by 70 percent in October, and one estimate had it that this year they could be down by 17 percent to 180 billion. They could even fall to 165 billion.

You have to wonder what would convince a government to decide—it cannot have been unaware of the consequences—to create such chaos in a market where it has the major financial stake. The charitable interpretation might be that it genuinely wanted to cut smoking in a country where a lot of men continue to indulge in the habit. And, to be fair, if this were the intention, then it has been successful, at least for the time being. Although about 20 percent of people who quit smoking in light of the Oct. 1 tax hikes quickly returned to their habit, by the beginning of November 62 percent of those who stopped smoking due to the price increases had not smoked a single cigarette in the meantime.

I’m still not convinced, however. Call me cynical, but I have a funny feeling that this will end up doing little else but increasing the government’s revenue from tobacco taxes. Still, I’m willing to eat my words if it turns out that both the incidence of smoking and tobacco tax revenue fall.