Faced with declining demand for tobacco, industry suppliers are turning their attention to cannabis.

TR Staff Report

The legalization of cannabis and related products in many jurisdictions is creating new opportunities for tobacco companies and suppliers facing stagnating sales of their traditional products.

While the Covid-19 crisis appears to have slowed the long-term decline in demand for some tobacco products—premium cigars in particular appear to have fared well during the crisis—the days of unrestrained growth are clearly over. Global Data predicted in September that tobacco companies would sell $651 billion worth of filter cigarettes in 2020, an 8 percent drop on sales of $707 billion in 2019. For plain cigarettes, the fall is higher at 11 percent, and in niche categories like chewing tobacco, forecast sales were expected to drop by 13 percent in 2020.

The data and analytics firm says the pandemic has prompted significant numbers of consumers to quit tobacco products, citing lower disposable incomes from reduced employment, fewer social settings in which to light up and increased awareness about the importance of respiratory health. This is on top of existing factors depressing demand for tobacco products, including growing health consciousness and anti-tobacco measures, such as smoking bans and taxation. Global Data expects it will take at least until 2023 for global tobacco sales values to fully recover.

Meanwhile, global demand for cannabis and related products continues to rise steadily. Euromonitor International believes global legal sales of cannabis could increase from $12 billion in 2018 to $166 billion by 2025—a potential increase of more than 1,000 percent. Much of that growth will come from legalizing sales that are currently taking place illicitly. In 2018, only about 8 percent of the global demand for cannabis was filled legally, hinting at the tremendous opportunity for growth.

Cannabis legalization has been gathering momentum. Alongside the U.S. presidential election in November, voters in several states approved ballot measures legalizing marijuana. In 2018, U.S. Congress had already legalized hemp with less than 0.3 percent THC, the psychoactive component in cannabis, in all 50 states.

In December 2020, the U.S. House of Representatives passed the Marijuana Opportunity Reinvestment and Expungement Act—a bill decriminalizing marijuana at the federal level. Then Senate Majority Leader Mitch McConnell refused to bring it to a Senate vote, but the outcome of recent elections has changed the outlook. With the Democratic party controlling the presidency and both chambers of Congress, the chance for federal legalization of cannabis appears to have increased significantly.

On the global stage, too, cannabis continues to gain acceptance. Late last year, the United Nations (U.N.) removed cannabis from Schedule IV of the 1961 Single Convention on Narcotic Drugs, where it resided alongside drugs like heroin. The change will open the door to more medical cannabis research. National governments will still decide how to regulate cannabis, but many states look to the U.N. for guidance.

Suppliers of the tobacco industry have been watching the developments with considerable interest. Around the world, tobacco farmers have either shifted to growing cannabis or added it to their repertoire as an additional income source. Zimbabwe, a leading producer of leaf tobacco, legalized cultivation of cannabis for medicinal use in 2019. Local officials have high hopes for the new crop, with some predicting Zimbabwe’s earnings from cannabis exports could outstrip those of tobacco by a factor of three. Treasury spokesman Clive Mphambela expects the country’s cannabis sales to reach $1.25 billion in 2021. By comparison, Zimbabwe earned $444 million from the 2020 marketing season that closed in August, according to the Tobacco Industry and Marketing Board.

Malawi, too, is gearing up to start commercial production and processing of cannabis for medicinal and industrial use. In February 2020, Malawi’s parliament passed a bill that makes it legal to cultivate and process cannabis for medicines and hemp fiber used in industry but stops short of decriminalizing recreational use. The country recently created a dedicated regulatory authority for cannabis. Despite steep licensing fees, many tobacco farmers have already applied for permission to grow cannabis. Their enthusiasm is understandable given that Malawi’s earnings from tobacco have fallen dramatically in recent years.

Elsewhere in the supply chain, companies that have traditionally catered to the tobacco industry are also eyeing cannabis. For example, Hoffmann Neopack, known in the tobacco industry as a supplier of tins and tubes, organized a webinar last year exploring best packaging practices for cannabis products.

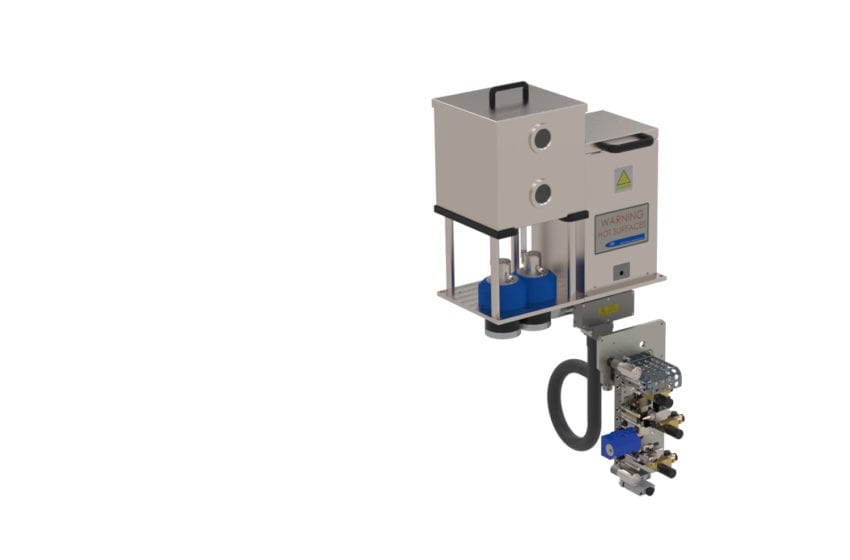

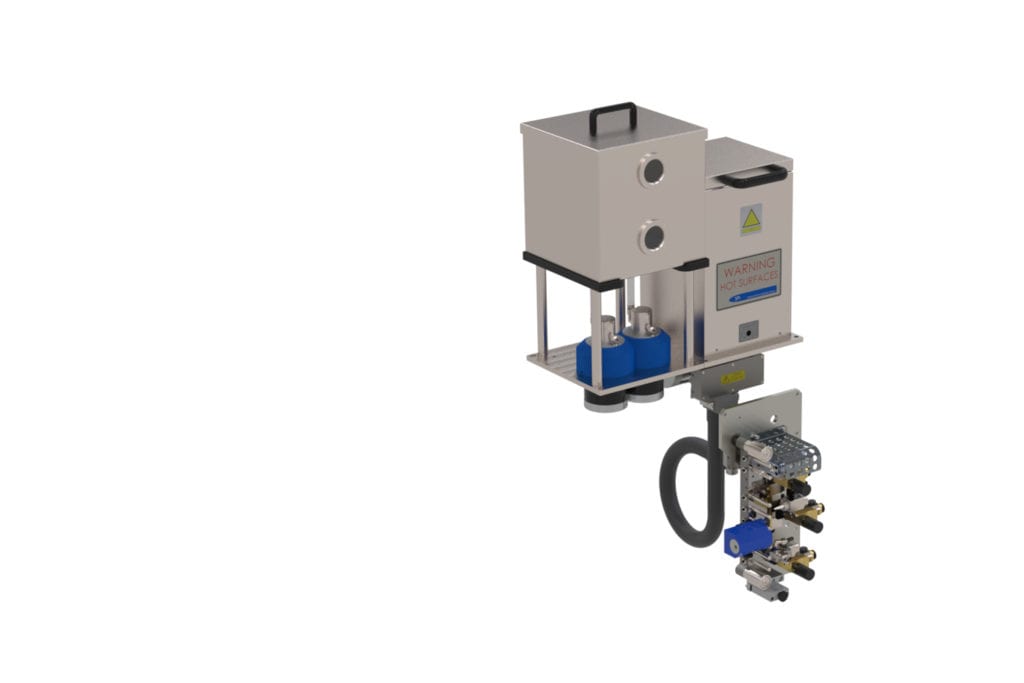

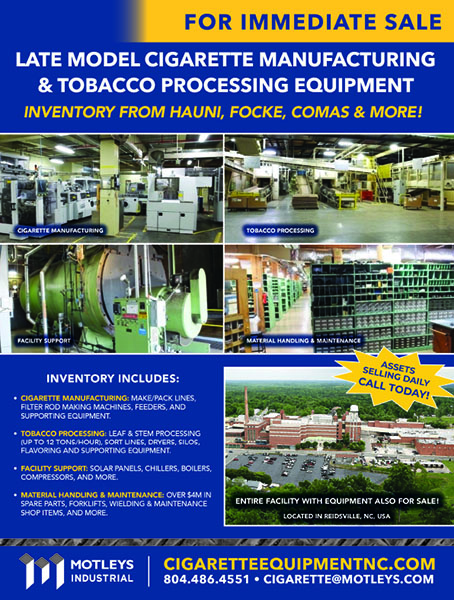

Even machinery makers have gotten into the game. Evans MacTavish Agricraft, a longtime supplier of leaf tobacco processing equipment, now offers a broad portfolio of machinery for all steps of marijuana processing—from treating the raw material to overwrapping of the filled cannabis preroll packs. Hauni Maschinenbau, best known for setting speed records with its cigarette production machinery, has also entered the cannabis market. At a recent open house in Richmond, Virginia, USA, the company launched three machines for cylindrical preroll making as well as a range of accompanying equipment.

Traditional tobacco companies, too, have ventured into cannabis. In late 2018, U.S. market leader Altria Group acquired a 45 percent equity stake in Cronos Group, a leading global cannabinoid company, headquartered in Toronto, Canada. British American Tobacco recently launched its first CBD vapor product, Vuse CBD Zone, in Manchester, U.K.

Of course, investing a newly legalized sector presents risks, and some investments have soured. In January, Pyxus International announced that it would divest its cannabis business in order to focus on its more profitable tobacco and e-liquid operations. Regulatory confusion and failures in corporate executions have brought back some of the more outlandish forecasts to what are perhaps more realistic expectations.

Despite such teething problems, however, the long-term narrative remains one of growth: Cannabis will likely continue to gain momentum, and tobacco industry players would do well to keep an eye out for opportunities in the segment.