The Philippines is rebuffing outside forces seeking to derail its tobacco harm reduction policies.

By Stefanie Rossel

The Philippines is about to become the first country in the Asia-Pacific region to introduce risk-proportionate vaping legislation. By doing so, it is defying the World Health Organization, which has been skeptical about tobacco harm reduction (THR). The Philippines is part of a small group of nations that have started scrutinizing the influence of big WHO donors on national tobacco control policies.

In December 2020, two Filipino congressmen called for a congressional investigation into the Philippines Food and Drug Administration’s (PFDA) acceptance of funding from the International Union Against Tuberculosis and Lung Disease, which is popularly known as The Union. The Union is a major beneficiary of Bloomberg Philanthropies, a foundation created by U.S. billionaire Michael Bloomberg, that is known for its anti-vaping agenda. By accepting funding from Bloomberg, the representatives argued, the PFDA violated a number of critical regulations in the public sector. These include the Anti-Graft and Corrupt Practices Act, the Code of Conduct and Ethical Standards for Public Officials and Employees, the Tobacco Regulation Act, the Lobbying Act and the Foreign Agents Registration Act. The PFDA’s director general had previously admitted during a public hearing that the agency had received more than $150,000 from The Union, essentially to hire employees to outline the Philippines’s tobacco control policy.

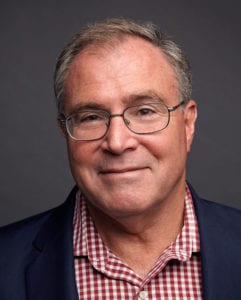

Since 2006, Bloomberg Philanthropies has invested $1.1 billion to advocate for tobacco control policies worldwide. These policies are largely based on MPOWER, a set of demand-reduction strategies derived from the WHO Framework Convention on Tobacco Control (FCTC). A substantial portion of Bloomberg Philanthropies’ work has advanced tobacco control in many countries. However, support for adult smokers to quit—a component of MPOWER—has been completely ignored by the organization and its partners, according to Derek Yach, founder and president of the Foundation for a Smoke-Free World (FSFW). “These organizations see THR as a ploy of the tobacco transnationals,” he says. “With this perception, they ignore the vast benefits of THR and its potential to end smoking in this generation.”

Bloomberg Philanthropies and its partners are not investing to develop research and capacity in low-income and middle-income countries (LMICs) on THR and the safety of associated products, notes Yach. “By continuing to ignore the growing evidence, including from the Royal College of Physicians, showing e-cigarettes and other reduced-risk products are much less harmful than combustibles, Bloomberg and others are impeding important progress in the fight to end smoking,” he says.

Far-Reaching Influence

Around 80 percent of the more than 5 trillion cigarettes smoked globally each year are consumed in LMICs. By its own reckoning, Bloomberg Philanthropies is present in 110 LMICs through its Bloomberg Initiative to Reduce Tobacco Use. These include India and China, which together account for nearly 40 percent of the world’s smokers. The initiative, Bloomberg Philanthropies claims on its website, “is helping cities and countries implement measures that are proven to reduce [tobacco] use and protect people from harm.”

The initiative’s influence extends through all levels of society, media and government. According to an analysis by Michelle Minton, senior fellow at the Competitive Enterprise Institute (CEI), it seems to be aimed at imposing its will on the developing world. Minton’s findings are based on a leaked document obtained by CEI, which detailed the 2017 LMIC strategy of the Campaign for Tobacco-Free Kids (CTFK), Bloomberg Philanthropies’ largest beneficiary. The CTFK is part of a complex network of Bloomberg Philanthropies-funded organizations, all of which pursue a zero-tolerance approach to all tobacco use.

For these organizations, the term “tobacco” includes reduced-risk products (RRPs)—essentially, anything containing nicotine that is not a pharmaceutical nicotine replacement-therapy product. The CTFK has attempted to influence political processes and key players in various countries with the help of partnerships and often financial collaborations with activists, think tanks, professional associations, media, universities and governments. According to Minton, the CTFK and its grantees pay to manipulate news coverage. She calls the CTFK’s strategy “a highly synchronized chorus of interdependent interest, coordinated from afar.”

Lacking the funds to conduct their own THR research, most LMICs follow the WHO’s guidelines unquestioningly. In recent years, their delegates have continued to confirm the WHO’s anti-THR stance during the FCTC Conference of the Parties (COP) sessions. The next summit, COP9, which was postponed due to Covid-19, will now take place in November 2021 and presents another opportunity for delegates to make a change.

The influence of Bloomberg and his fellow WHO sponsor, Bill Gates, has also been brought to light by a number of recent articles. A study by Mitsuru Mukaigawara et al., published by Wellcome Open Research, examines the extensive use of media and academic influence by Bloomberg and the Gates Foundation to drive the global tobacco control agenda. “Highlighted by their influence over the World Bank and WHO, the authors show that the two organizations have been able to create a multilayered approach that touches many of the key stakeholders and undermines national sovereignty in tobacco control,” Yach explains. “Their broad and tight grip on various tobacco control activities will be tough to overcome. What may well happen, though, is that the weight of scientific evidence favoring THR will in time break through into the corridors of future WHO COP sessions.”

THR Discussions Postponed

Yach is less optimistic that such evidence will change minds among participants in the upcoming COP. “Unfortunately, due to the travel restrictions, FCTC-COP9 will be a virtual event with limited technical discussions, essentially tabling THR discussions until COP10 in 2023,” he says. “Even before this announcement, the WHO’s lack of transparency in its reports on novel products reveals a prohibitionist stance on THR.”

Over the past decade, Yach observes, media access to the FCTC has been constrained, and documents are published by the secretariat without formal member state input. “In fact, for the upcoming COP9 meeting, documents containing serious implications for THR are presented to be ‘noted’ without being subject to the usual United Nations practice of being thoroughly discussed and revised,” he says. “Many LMICs may well be persuaded by Bloomberg grantees to go ahead with bans and prohibitions of THR products supported or encouraged by WHO documents. These decisions will undermine the long-term health of their smokers.”

In the run-up to the conference, the FSFW has started a campaign to inform COP9 delegates on the potential of THR. “Our goal is simple: Ensure that all involved directly or in advisory roles to member states engaged in COP9 are equipped with the best scientific data and information,” says Yach.

The FSFW’s new Commission Report: Reignite the Fight Against Smoking, created by an international team of experts, highlights the opportunities to reduce the death and disease caused by smoking through use of THR and, in time, more effective cessation, Yach says. “The report provides member states with up-to-date data and insights about the value of innovation in driving changes in some companies. It spotlights which countries are making the most progress and which are badly lagging.” The report also highlights the need for doctors to take a more supportive role in advancing use of cessation and THR in LMICs, and the need for industry to be more aggressive in addressing youth access and marketing, according to Yach.

The Commission Report, available at www.fightagainstsmoking.org, is complemented by the Patent Landscape Report, which is available on the FSFW website and presents an overview of current patents for THR technologies. “The FCTC failed to recognize importance of intellectual property and technological innovation,” says Yach. “Both are now driving change in the industry and further exacerbating the advantages developed countries have over LMICS as patenting activities in developing and least-developed countries are not comparable to those in the developed world.”

Progressive Stance

The Philippines is not the first country to reject the influence of Bloomberg Philanthropies on its tobacco control policies. In 2017, the government of India prevented two not-for-profit organizations funded by Bloomberg Philanthropies from carrying out tobacco control work in New Delhi after they failed to disclose their financial backers. In March 2021, a Mexican activist revealed that a proposal to prohibit the import, distribution and sale of vaping products had been formulated by CTFK’s legal advisor for Latin America.

THR proponents hope that the Philippines will become a model for other Asia-Pacific countries where smoking prevalence is high and RRPs are currently either banned or restricted. After years of opposition to RRPs, the Philippine House of Representatives in early 2021 proposed House Bill 9007, which will regulate electronic nicotine-delivery systems (ENDS). If approved, the Philippines Department of Trade and Industry, in consultation with the PFDA, will be assigned oversight of ENDS regulation.

Among other things, the bill stipulates that only retailers will be allowed to sell electronic nonnicotine delivery products and heated-tobacco products (HTPs). Retailers will be required to check buyers for a valid government-issued ID. Manufacturers, importers and distributors will need to comply with certain packaging and health requirements. Use of RRPs will be allowed only in designated areas, and the sale or distribution of these products will be prohibited within 100 meters of schools, playgrounds and other facilities frequented by minors. (Currently, the minimum age for purchase of ENDS and HTPs in the Philippines is 21.) Bill 9007 passed the House in May with a comfortable majority of votes; the Senate was expected to vote on it this fall.