How Mayiwepi Jiti became a successful commercial grower in Zimbabwe’s male-dominated leaf tobacco industry.

By Stefanie Rossel

In sub-Saharan Africa, more than 60 percent of employed women work in agriculture. As shown by the example of Malawi (“This Is a Man’s World,” Tobacco Reporter, May 2021), they are at a significant disadvantage compared to men as women often lack control over land and access to financing while being excluded from important links of the agricultural value chain. Being dependent on a male relative to access the land, they are vulnerable; a husband’s death, a divorce or simply a man’s change of mind can leave a female farmer landless overnight.

Zimbabwe is no exception. Tobacco, which today is grown primarily by smallholder farmers, accounts for about 40 percent of the country’s exports. According to the Borgen Project, approximately 72 percent of the country’s population lives in chronic poverty, and 84 percent of Zimbabwe’s poor live in rural areas. Zimbabwe has yet to recover from the 2008 financial crisis. Its gross domestic product (GDP) has been declining since 2013, in part due to stalling investments and adverse climate conditions that hurt the agricultural sector.

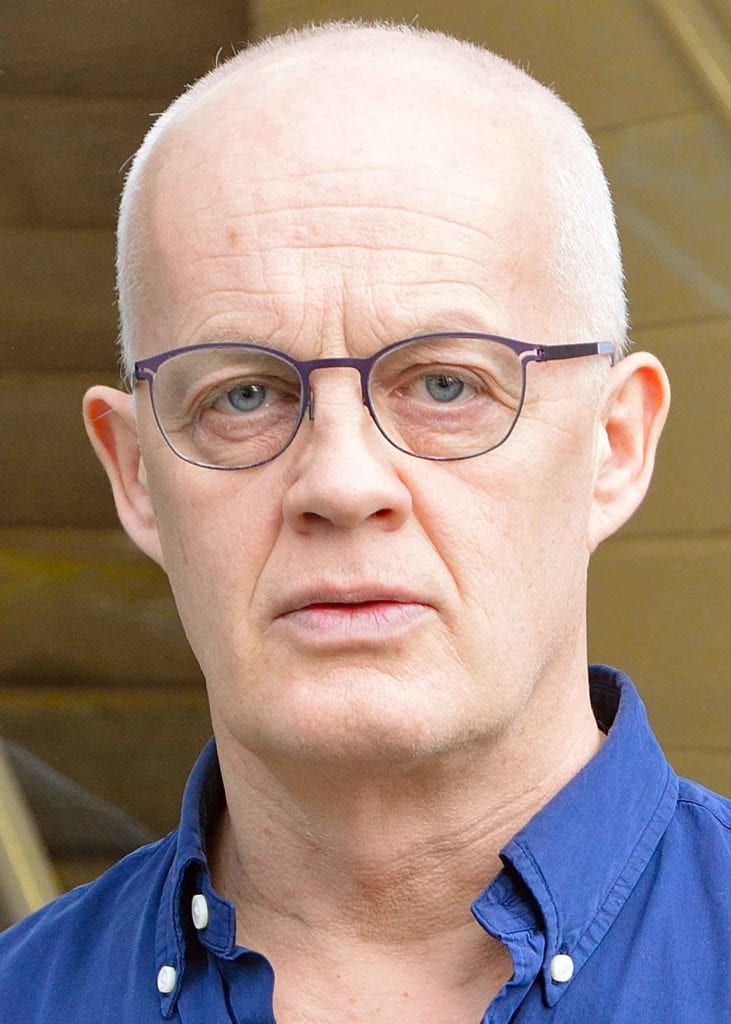

“Zimbabwean women played and are still playing a pivotal role in resuscitating the country’s agricultural sector after its dilapidation by the Zimbabwean-British relations,” explains Mayiwepi Jiti. As a successful commercial farmer employing more than 200 permanent and seasonal workers and as the founder and president of the Zimbabwe Integrated Commercial Farmers Union (ZICFU), she is a rare example of a powerful woman in the country’s agricultural sector.

“Women are bearing positive results on the country’s economy, where tobacco accounts for 10.7 percent of the country’s GDP. However, the Gender Links 2013 Barometer on Zimbabwe reported that although Zimbabwe’s economic framework calls for women’s participation in key sectors of the economy, there are no gender-responsive policies in the agriculture sector. Plans are underway for the government to align legal frameworks that would ensure equal opportunities between men and women.”

Before the land reform of 1999, not a single woman owned a commercial farm in Zimbabwe’s mostly patriarchal commercial farming system. Females would inherit land only when there were no male heirs. Things gradually began to change from 2000, when the government redistributed land to redress the imbalances of landownership and a small number of Zimbabwean women secured land and became commercial farmers. Due to lack of funding in agriculture, contract farming was introduced as a temporary relief, but conditions remained unfavorable, especially for women.

Out of more than 110,000 small-scale farmers today, 39.5 percent are women, says Jiti—an increase triggered by a rise in the number of single mothers, either widowed or divorced or pressed with financial responsibilities. In tobacco farming, these women are accepted as equal partners when they are selling tobacco on the tobacco floors, but due to gender-based constraints and shortages of funds to compete with the patriarchal society, they are not yet fully involved in all stages of the tobacco value chain, Jiti points out. “This makes it difficult to be involved in decision-making and inclusion on finance issues. Women have a very limited voice in that aspect.”

In less than two seasons, I proved both the financiers and family members wrong

Mayiwepi Jiti

Rocky Road

Reflecting on her own career, Jiti says that raising her voice and getting heard as an entrepreneur was not easy. “I faced a lot of challenges when I took over running of the family farm when my husband suddenly passed away in 2004. I had small children to look after, I had over 300 farm workers who looked up to me and I had a farm to work on to make a living and run as a professional enterprise,” she says.

“Banks shunned me because of gender, and they looked down upon women as they had a feeling that as a woman, I was a nonperformer, and they did not know that behind every successful man there is a woman. Culturally in Zimbabwe, women tend to submit themselves to men and believe that it is the man who should initiate first before they follow. While men are discussing important issues, whether business or family issues, women are supposed to keep quiet or sometimes act behind the scenes. In most cases, the women are the brains, with brilliant and intelligent ideas. They are good at implementation and [are] naturally hard workers,” says Jiti.

A primary schoolteacher by training, Jiti married a man with a farming background. Together, they bought a farm in 1996 and set up the respective infrastructure, which involved clearing land, making bricks, constructing tobacco barns and preparing the land to plant a crop. Three years later, when Jiti was pregnant with twins, her husband persuaded her to resign from her job. Instead of teaching, Jiti became involved in farm work. “It was like he fully prepared me to eventually take over farming after him,” she says.

With both coming from farming backgrounds and having a lot of passion for agriculture, it was not difficult for her to proceed after her husband died in a car accident. At that time, they had just started construction of a dam for irrigation. The banks immediately stopped funding the project. “They demanded that I pay back what had been borrowed simply because they thought [that] as a woman, I was never going to finish off the project. Obviously, they judged me based on gender.”

However, Jiti managed to construct the dam to 75 percent of its intended capacity without bank funding. “I achieved this through planting and selling cash crops like potatoes, cabbages, tomatoes, with the assistance of well-trained supervisors whom I had groomed with the assistance of my husband.”

Today, Jiti grows tobacco on 80 hectares, whereas 50 hectares each are dedicated to maize and wheat, respectively. Most of the workers she employs are housed on the farm in self-contained houses with clean water and electricity.

Successful Exporter

The start was tough. “Running the farm and the family was a huge responsibility which needed sobering up and tireless hard working. I had very limited time to rest as I had a huge responsibility. My two children were in junior primary school when my husband passed on. Most family members looked down upon my abilities as a single mother and businesswoman. But in less than two seasons, I proved both the financiers and family members wrong. I pulled through and became a very successful and prominent farmer as I managed to not only look after extended family members, but I also successfully joined the male and white dominated export field of fruits and vegetables to Europe and won an international gold award on production of quality products.” Due to racial discrimination, black farmers were not allowed to venture into export, she adds. As information was not easily and readily accessible, it wasn’t an attractive field of business for them either.

While more women are now in leadership positions, Zimbabwean farming is still dominated by men, according to Jiti. Women, she says, are often told to give their ideas to their husbands, who then take the credit. What’s more, female entrepreneurs also suffer the challenge of defying social expectations. “On the one hand, men tend to believe that to be successful in any business, there is a need to be competitive, aggressive and sometimes harsh. On the other hand, some successful women out there are mostly true to themselves and generally confident with their work,” says Jiti. “The societal perspective needs to change, and women must be embraced for who they are. They ought to be given a chance to display their wings on their own and not to be made to compete with men, who are born inherently different.”

Another issue is that most women have no access to funding. “In my opinion, if there are government grants, they must benefit women equally as much as they benefit most men,” says Jiti. “Other challenges need to be addressed as well. Examples are corruption, the bottleneck system on the certification on export permits and the middlemen in the tobacco industry who buy farmers’ produce at low prices and resell it at huge markups.

Contract farming, she believes, plays a positive role to most women farmers in Zimbabwe, where tobacco is typically sold in auctions. Under the current tobacco-selling regulations, farmers receive 60 percent of their tobacco payments in U.S. dollars and the remainder in Zimbabwe dollars.

Farm inputs are priced in U.S. dollars, and the Zimbabwean dollar has been subject to considerable inflation. “In a country like Zimbabwe, which is believed to have many small-scale farmers who are unable to participate in intensive agricultural production and lucrative export markets, contract farming will be the way to go, at least for now,” says Jiti. “It is the women who suffer most as they have restricted access to loan facilities, insurance, are treated unfairly, etc. Contract farming has been tried before and has proven to be useful to most women. I therefore believe that if it is upheld, it assists in the promotion of most women into intensive agricultural production.”

Representing Farmers’ Needs

Jiti founded the ZIFCU in 2018 after facing challenges with the existing farmers union, ZFCU, where she was vice president of administration. “ZCFU has been registered as a private company benefiting a few individuals and allocating themselves union properties that were acquired by farmers for the benefit of the union members,” Jiti says. “Being a woman founding the union would not be taken lightly by the men-dominated ZCFU as they think it is a direct challenge to their union and are scared of the competition as they are quite aware that women leaders deliver. As a result, they are trying by all means to tarnish my image by false accusations. It is so sad to note that ZCFU leadership has very little knowledge about agriculture, making them very passive leaders in as far as farming challenges is concerned.”

ZICFU provides support networks to farmers, ensuring they have access to resources and skills training and development for them to effectively utilize the land and market their produce. Groups represented by the association include subsistence agriculture, dairy farming, ranching, poultry and hobby farming. “ZICFU creates collaboration between farmers regardless of gender and other organizations, government and private partners to enable them to get the best out of their land,” Jiti explains.

Because irrigation equipment is expensive, small-scale to medium-scale Zimbabwean farmers tend to produce only rain-fed crops, which means low productivity. Most smaller farmers depend on government input handouts, which do not encourage them to expand production. When given these free packages, some farmers sell them to earn a small income for immediate household needs, eroding their credibility as borrowers in the eyes of the banks, according to Jiti. “The huge interest rates charged by the lenders are exorbitant and leave the farmer always in debt.”

To eliminate this—and to deal with the effects on precipitation of climate change—more dams must be constructed. “In addition, there is need for the Zimbabwean government to constantly give grants to the deserving citizens so that those that are into commercial farming can afford irrigation equipment and other inputs that assist them in their farming activity thereby also bringing foreign currency to Zimbabwe.

“I also believe that farmers need to be educated on the importance of evolving from subsistence to commercial agriculture. Commercial farming is highly rewarding, not only for the farmer but for the country at large,” Jiti says. Furthermore, she argues, people need to be educated on the importance of honoring the credit facilities. “This farming business can only succeed if we as farmers observe the need to be honest amongst ourselves and to the bank. The banking sector should charge reasonable interest rates for the sustainability of the farmers.”

It is at this juncture that ZICFU comes in as an organ that advocates for positive change in agriculture. “Our aims and objectives are centered on the evolution in the agriculture sector and being the voice of the women who are still downtrodden, who also need emancipation and empowerment. In addition, ZICFU educates farmers to stand on their feet instead of constantly relying only on government grants and to embrace the digital world. We therefore intend to bring more awareness campaigns to the Zimbabwean farmers from all spheres, which will assist them in moving from small-scale farming to commercial farming, which is also in line with the Zimbabwean economic blueprint.”