Minimizing the environmental impact of tobacco packaging materials

By George Gay

It seems that every day we are confronted with news that yet another factor is adding to those that are already known to be leading us toward environmental catastrophe. And the timetable of the approaching catastrophe is shortening by the day; so, as another story in this issue suggests (see “Our Better Nature,” page xx), we now have perhaps only a decade to sort things out. Under these circumstances, it seems reasonable that we should be doing all that we can, as quickly as we can, to reverse or at least lessen the environmental damage that we have caused and continue to cause.

The tobacco industry uses packaging materials, some of which, with the right incentives, could be substituted with those more environmentally friendly. And, in the case of both traditional and substitute materials, it is useful to keep an eye on production processes so as to control waste because even though “waste” can be recycled, recycling processes have unavoidable inefficiencies.

But controlling waste in a time of falling volumes produces its own problems. Lower volumes mean lower demands for materials, such as packaging—something that, purely from an environmental perspective, could be seen as positive. But, as ITC Packaging told me, current market dynamics mean that even as volumes are falling, the number of stock keeping units and design complexity are increasing, and for a packaging company, this can conspire to produce higher levels of waste.

There are two major ways in which such waste can be minimized, ITC said. Process waste can be reduced by optimizing print paperboard layouts in conjunction with customers and tool suppliers. New technologies, such as digital printing, can be used for very short runs, including those involving limited edition packs. The consumption of ink can be reduced by using laser cylinders rather than electromechanical cylinders. Machine sensors can be upgraded to allow smaller print-register marks to be read, thus reducing board trim waste. And double-sided tapes can be used in reel-to-reel products to enable the complete use of board reels, despite joints.

Secondly, machine setup waste can be reduced by sequencing jobs of similar profiles, colors, etc., and by doing preparatory work in pit stop mode, whereby, for instance, ink preparation and tooling are carried out in parallel.

Presentation

But back to the materials themselves. I was recently looking back at the revised versions of EU Tobacco Products Directive that entered into force on May 19, 2014, that became applicable in member states on May 20, 2016, and that lays down rules governing, among other things, the presentation of tobacco and related products. Under the directive, unit packs of cigarettes must have a cuboid shape, while unit packs of roll-your-own tobacco must have a cuboid or cylindrical shape or be in the form of a pouch. At the same time, a unit pack of cigarettes must include at least 20 cigarettes, while a unit pack of roll-your-own tobacco must contain a minimum of 30 grams of tobacco. In addition, the directive specifies the materials packs may be made of and their form, down to the requirement that, for instance, flip-top lids must be hinged only at the back of the pack.

I take it that those who devised the above had in mind to lessen the negative health impact of tobacco consumption by ruling out smaller and gimmicky packs that, in their view, could entice people to smoke when they might otherwise not do so.

I don’t want to belittle the efforts of such people, but I find it almost impossible to imagine how they would be able to convince themselves that many people—anybody, even—would be saved from premature death by the imposition of such restrictions. Why, if the objective was to protect human life, wasn’t the emphasis put on environmental rather than aesthetic issues surrounding tobacco packaging?

For instance, the EU could have specified that all cigarette packs have either no inner liner or only easily recyclable or compostable paper inner liners. And it could presumably have specified that these inner liners were either plain or printed with environmentally friendly inks. Of course, it might be said that leaving inner liners out altogether might impact the freshness of the cigarettes, but, looked at from the EU’s point of view, that would be another plus—another way of making cigarettes less attractive.

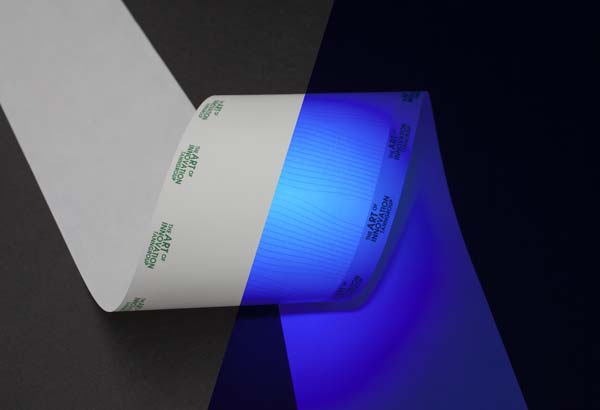

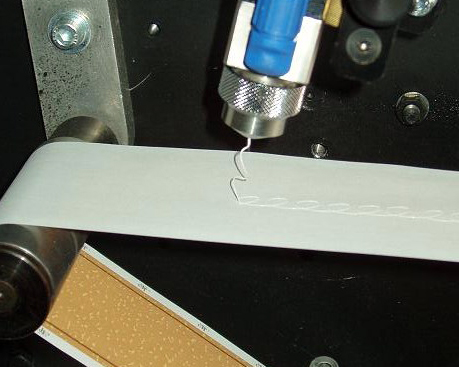

And there is always the paper inner liner option. BMJ, for instance, which has been supplying the tobacco industry with paper and foil inner liners since the mid-1990s, has recently been offering printed paper inner liners. But as you would expect in a competitive cigarette market, the traditional, tactile and attractive foil inner liners are the preferred option. Only regulation is going to make the seismic shift that is necessary to help—in a minor way, admittedly—save the world.

Planning for the future

Unfortunately, I don’t think that we, the adults, will ever replace aluminum foil with paper or do all of the other things to all of the other packaging of all of the other products necessary to save the environment. We have allowed a certain type of capitalist to convince us that the market will sort things out—that there is no need for government regulations. This, of course, is nonsense. But the problem is that the argument against regulations starts to resonate with people when opponents of such rules can point to those that, for instance, specify that the hinges of flip-top packs must only be situated at the back of a pack. I mean, what’s the point? Once a pack is sold to the consumer, it is the consumer who decides what is the front, back or side. Some years ago, it became the fashion among a certain group of people in the U.S. to open soft packs at the bottom, which, you might say, became the top.

Apparently, only children can see through such nonsense. Toward the end of last year, an academic in the U.K. suggested that children as young as six should be given the vote, and I, like a lot of people my age, I would imagine, nearly fell off my perch with apoplexy. But after I’d downed a stiff mug of steaming cocoa, it became easy to see what he was getting at. According to a Dec. 6 story in The Guardian, the head of politics at Cambridge University, David Runciman, made his suggestion because the U.K.’s aging population meant young people were now “massively outnumbered,” creating a democratic crisis and an inbuilt bias against governments that planned for the future. And lowering the voting age to 16 was not radical enough to address the problem.

Certainly, the environment must be an example of how governments have failed to address even threats of catastrophes forecast to overwhelm us in just a few decades. I must admit that I’m not convinced that a 6-year-old would trade her plastic toy to help stop a glacier melting, but her 10-year-old sister might, or she might at least be willing to forgo the plastic packaging around the toy.

Children seem particularly exercised by the issue of plastic pollution, much of which is caused by packaging, some of which is unnecessary and some of which could and should be substituted. In part, this is no doubt to do with children’s fascination with nonhuman animals and the distress that the children feel when they learn of such animals suffering from the ingestion of plastics. Many adults, on the other hand, after years of eating bits of animals, have become desensitized to such suffering and don’t seem capable of grasping the scale of the problems we face. Certainly, they don’t seem collectively to be capable of addressing these problems in an even halfway effective manner.

But some help is at hand. Parkside told me that it had recently launched recoflex-PE, a fully recyclable single polymer flexible packaging laminate with barrier properties and sealing performance that mirror a range of commonly used laminates in the tobacco packaging sector that are not currently recycled.

“Designed to support a circular economy, recoflex-PE is made from 100 percent polyethylene (PE), which enables the packaging material to be recovered via the established carrier bag collection and recycling infrastructure in retailers,” the company said. “Consumers can simply take their packaging to retail stores with carrier bag collection points.

“The innovative laminate can be used for most flow wraps, pouches or bags that require a high barrier to protect product freshness.”

This is just part of Parkside’s response to environmental concerns over packaging. The company also said that it had developed Park2Nature, a range of flexible packaging materials that were fully home compostable and designed to disintegrate within 26 weeks in ambient conditions—materials that have been granted full accreditation from TUV (Germany’s Technical Inspection Association). “The packs are rigorously tested for eco-toxicity and a host of other criteria against [technical standard] EN 13432,” the company said.

“Parkside is the only company in the world today with a fully accredited compostable packaging range and was the first U.K. company to secure Australasian Bioplastics Association (ABA) accreditation for its compostable designs.”