Altria is determined to lead the shift toward less-harmful products.

Timothy S. Donahue

The tobacco industry is changing rapidly. Next-generation tobacco products are quickly gaining share. Altria, the largest tobacco company in the U.S., and its subsidiaries have been steadily building a portfolio of noncombustible, nicotine-containing products with the potential for reduced harm. Marty Barrington, Altria’s chairman, CEO and president, says, “It’s a portfolio approach, and ‘portfolio’ is an important word.”

The tobacco industry is changing rapidly. Next-generation tobacco products are quickly gaining share. Altria, the largest tobacco company in the U.S., and its subsidiaries have been steadily building a portfolio of noncombustible, nicotine-containing products with the potential for reduced harm. Marty Barrington, Altria’s chairman, CEO and president, says, “It’s a portfolio approach, and ‘portfolio’ is an important word.”

During Altria’s 2017 investor day, held in Richmond, Virginia, USA, in early November, Barrington told attendees that while Altria has led the U.S. tobacco industry on the combustible side of the business for decades, it has simultaneously been preparing to win in the “emerging opportunity to provide adult tobacco consumers with noncombustible, nicotine-containing products” that are authorized by the U.S. Food and Drug Administration (FDA).

“We strongly believe that businesses that are great over the long term—like ours—both maximize today’s business while preparing for tomorrow’s,” said Barrington. “And Altria has been doing just that.”

Not all consumers want the same experience, so it’s important to provide them with product choices, said Barrington. At the same time, he cautioned that too many initiatives can dilute focus. Through its subsidiaries Nu Mark and United States Smokeless Tobacco Co. (USSTC), Altria is concentrating on the three platforms that it believes presently hold the most promise for U.S. adult tobacco consumers: smokeless tobacco and oral nicotine-containing products, e-cigarettes/vapor products and heat-not-burn tobacco products.

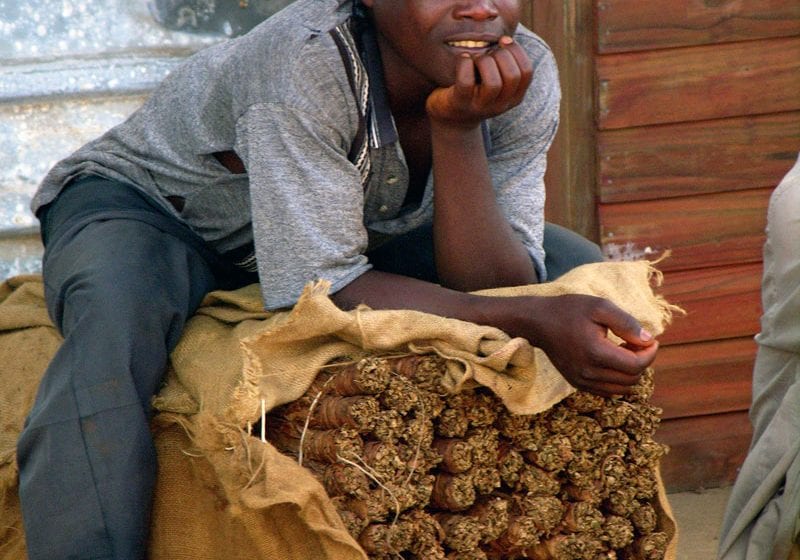

Currently, the most profitable noncombustible tobacco product in the world is smokeless tobacco. An estimated 6 million U.S. adults use smokeless tobacco, and many of them are former cigarette smokers, according to research from the U.S. Centers for Disease Control and Prevention. This platform also includes other oral tobacco and nicotine products, including snus as well as nicotine discs and chews.

Brian Quigley, president of USSTC, said his company plans to file a modified-risk tobacco product application (MRTP) with the FDA for its Copenhagen snuff in the first quarter of 2018. “We believe USSTC is uniquely positioned to achieve this claim because we have been conducting the most comprehensive assessment of the health effects of smokeless tobacco in almost 30 years,” said Quigley.

The Skoal brand also plays a targeted role in USSTC’s harm-reduction strategy, according to Quigley. While growing profitability on Skoal overall, the company is investing to grow Skoal flavor blends and snus. “These products appeal to adult smokers who are interested in smokeless alternatives but are looking for familiar flavors and manageable forms to help them transition,” says Quigley. “Skoal snus is specifically positioned for adult smokers who are interested in oral alternatives to cigarettes, but who want a spit-free option.”

USSTC is also testing Verve, which is designed to provide adult smokers with the ability to use tobacco discreetly, according to Quigley. “We’ve developed four forms of Verve: discs, chews, chewable dissolvables and melts—all in four different flavors. In 2018, we plan to expand the sale of Verve discs at retail in other geographies and through e-commerce,” he says. “We also plan to file our first Verve premarket tobacco [product] application [PMTA] in 2018.”

Embracing vapor

There are an estimated 27 million vapers worldwide, including 10 million Americans, according to Barrington. That makes the U.S. the largest vapor market in the world. Many of these vapers are former cigarette smokers. Nu Mark’s MarkTen e-cigarette, which is available in about 65,000 retail locations and does a substantial online business, has a U.S. share of 13.5 percent in mainstream channels, according to Barrington. “In major chain accounts where it’s been selling for the full third quarter, it’s even higher, at 27 percent,” he said.

Jody Begley, president and general manager of Nu Mark, said 20 million U.S. adult smokers who have tried vapor products went back to smoking cigarettes. “With improved products and accurate relative risk information, we believe we can accelerate adult smoker conversion to e-vapor,” says Begley. “I fully expect Nu Mark to achieve our long-term goal, which is to lead the U.S. e-vapor category through a portfolio of superior reduced-risk products that adult smokers and vapers choose over cigarettes and that generate cigarette-like margins at scale.”

Adult smokers and vapers are looking for a range of different formats, flavors, nicotine levels and vapor volumes in their search for products that will help them quit smoking cigarettes. In response, Nu Mark has developed a portfolio of products that addresses a broad spectrum of adult consumer preferences, which will be required to lead the U.S. vapor market, according to Begley. Nu Mark plans to file PMTAs for its MarkTen products, including MarkTen Bold, in 2018, with MRTPs to follow.

Through a joint development agreement with Philip Morris International (PMI), Nu Mark has exclusive rights to commercialize its Mesh technology, which it put on the U.S. market before the FDA’s Aug. 8, 2016, deeming deadline. The product consists of a closed tank of e-liquid that is heated through a mesh-like metal plate, rather than the traditional wick and coil method. “We’ve received positive results from our initial consumer research, and as a result, we plan to further test this product—called Apex in the U.S.—as a line extension under the MarkTen brand,” says Begley.

Nu Mark has also been working to build strategic partnerships to expand its access to additional products and supply chain capabilities. Two examples of these efforts include a closed-tank product designed specifically for current open-system adult vapers, called Vim by MarkTen, and a small pod-based product, called MarkTen Elite. Begley said both these products were on the market by the FDA’s deadline.

Nu Mark also announced its recent acquisition of an additional pod-based product, called Cync, from Vape Forward. Cync is a small vapor device that uses prefilled pods, similar to the Juul.

Begley acknowledged that the open-system segment is likely to face some regulatory hurdles. “That said, open systems represent a large e-vapor segment and an excellent learning opportunity,” he said.

Recently, the company made a minority investment in Avail Vapor, one of the largest vape store chains in the U.S., with more than 100 company-owned stores.

Richmond-based Avail sells more than 100 premium Avail-branded e-liquids and a wide range of predominantly open-system devices. The company manufactures its own e-liquids in a state-of-the-art ISO-certified clean room and has a full-service analytical science laboratory to support regulatory compliance.

According to Begley, the investment is already paying off. “We’ve gained a better understanding of the vape store channel and adult open-system vapers, and [we] have access to extensive data around adult vaper purchasing patterns,” he says. “Through their retail stores, we’ve also learned a great deal about educating adult tobacco consumers about new products—insights Altria’s companies can apply to other areas of their reduced-risk portfolios going forward.”

Heated expectations

Altria’s heat-not-burn products have found success in numerous countries but are not yet authorized for sale in the U.S. market. The company hopes to change that, as it holds the exclusive right to commercialize PMI’s iQOS heat-not-burn platform and Heatsticks (tobacco sticks used in the device) in the United States once authorized by the FDA. IQOS will be marketed by Altria’s Philip Morris USA (PM USA) subsidiary, according to Sarah Knakmuhs, vice president of PM USA’s Heated Tobacco Products group.

“For those U.S. adult smokers seeking an alternative to conventional cigarettes, iQOS will offer a great sensory experience with similar nicotine satisfaction in a familiar format, using real tobacco, but with no ash and less lingering odor,” said Knakmuhs. “And at the same time, PMI’s extensive regulatory filings for iQOS present a compelling case for the product’s harm reduction potential. For example, the research demonstrates that iQOS reduces levels of 18 harmful and potentially harmful constituents identified by the FDA by over 90 percent, and [it] reduces levels of 15 known carcinogens by more than 95 percent versus conventional cigarettes.”

The FDA is currently reviewing both a PMTA and an MRTP application for the iQOS device and three variants of Marlboro Heatsticks, one non-menthol and two menthol. If authorized, PM USA will be able to sell iQOS in the U.S. without a modified-risk claim. PMI submitted the PMTA in March 2017, and the FDA accepted it for scientific review in August. The Tobacco Control Act guides the FDA to act on PMTA applications within 180 days of receipt, so a marketing order could be granted as early as February 2018, though the FDA controls that timing.

The MRTP application was submitted in December 2016, and the FDA accepted it for scientific review in May 2017. If authorized, PM USA would be allowed to explain to consumers that iQOS use presents less of a health risk than combustible cigarette smoking. The FDA will hold a Tobacco Products Scientific Advisory Committee meeting on the MRTP application in January 2018.

Moving forward, Altria expects to remain the undisputed leader in the U.S. tobacco industry, with the best products, brands, manufacturing and sales capability, and the strongest financial performance, according to Barrington. He says that decades of thought leadership and compelling advocacy to promote harm reduction has created both the enabling legislation and regulatory policy that now accepts harm reduction and innovation as the way forward for adult tobacco consumers.

“So, with all that, it should be apparent that we applaud the policy change toward innovation and harm reduction that the FDA announced in July. In fact, we believe the FDA has articulated a compelling vision for the future of innovative products,” says Barrington. “We welcome that future and embrace the challenge. And because we have been preparing for it for years, we are ready to compete, to win and to sustain the leadership that we cherish, but have never once taken for granted.”