Despite challenging times, optimism prevails among manufacturers of adhesives and adhesive application equipment.

By Stefanie Rossel

Tobacco industry suppliers have gotten used to annual statistics revealing declining cigarette consumption. News about additional restrictions is unlikely to shock them. Covid-19, however, took challenges to a new level, including for suppliers to tobacco adhesives.

“A prolonged period of high demand and tight supply is resulting in the highest inflation of raw material costs this industry has seen in living memory,” says Selda Akbasli, global business manager for rolled paper and tips at H.B. Fuller in the U.S. “Most forecasts indicate that costs will continue to increase through at least the end of the second quarter of 2022.”

Logistics also remain an issue, with global demand for containers remaining high and rates likely to further increase in 2022. “The logistics industry continues to be disrupted by Covid-19 and capacity shortages. Container availability and air capacity remain tight; waiting times for vessels outside of ports remain lengthy, and warehousing capacity continues to be a bottleneck,” says Akbasli. “Congestion at both ocean and rail terminals and container freight stations, namely in the U.S., persists. In Greater China, power outages and blackouts are impacting manufacturing outputs; however, demand for shipping container space is still high in the region. Our goal is to keep our customers informed as we monitor this dynamic and essential situation for our business.”

According to Akbasli, 2021 was a year like no other for manufacturers, with the supply chain crisis delaying goods and creating raw material shortages. “What it really highlighted is the importance of a robust and secure supply chain,” she says. “At H.B. Fuller, we are proud of how our teams in sourcing, manufacturing and logistics worked together with our global and regional supplier partners to ensure minimal disruption for our customers. Our range of adhesives with global formulations really proved their worth in providing manufacturing and sourcing flexibility.”

For 2022, the company will focus on people’s safety, sustainable product innovation and security of supply. To this end, H.B. Fuller is working with responsible global vendors who have strong partnerships within their supply chains networks, according to Akbasli.

Fit for the Future

Judging from market forecasts, Akbasli is confident that the value of the global tobacco business will continue to increase in the next years. “This industry is constantly evolving, and our customers are always open for opportunities to improve their product performance and overall manufacturing efficiencies,” she says. “We believe the changes we made over the past years, including our organization realignment and our approach to doing business differently during the pandemic, will serve as a competitive advantage in the years ahead.”

Tobacco remains an important segment for H.B. Fuller. The company, which had a fiscal net revenue of $2.8 billion in 2020, develops adhesive products for many markets across the world, from packaging to solar panel assembly, electronics to automotive, disposable hygiene to woodworking.

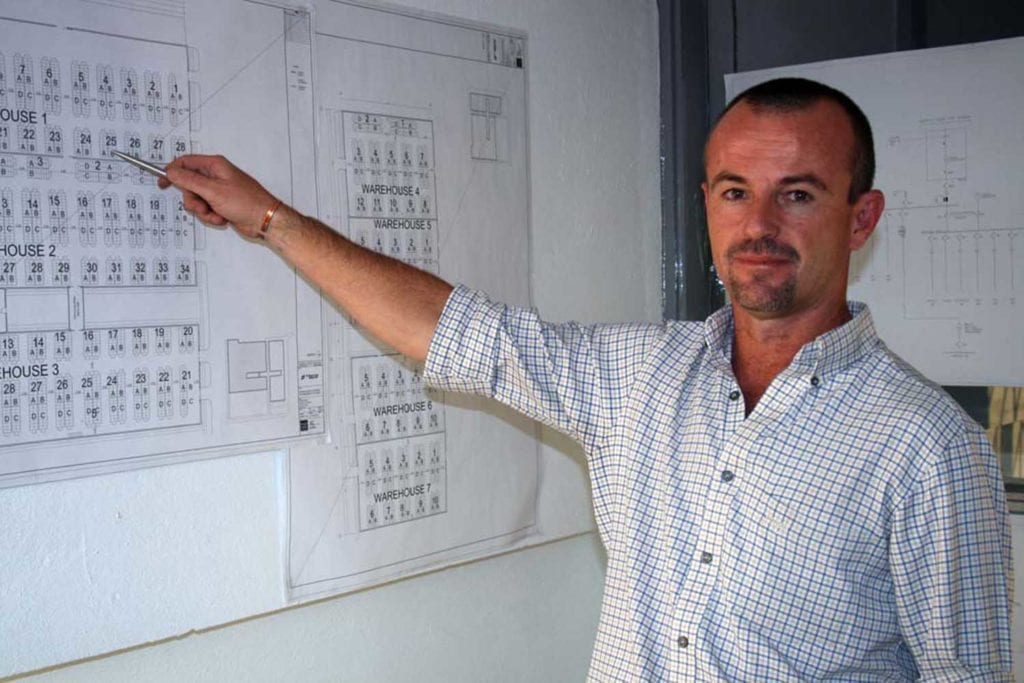

Floriano Erario is business development manager of tobacco packaging at Baumer hhs, a manufacturer of glue application and quality control systems. The company is headquartered in Germany and present in more than 90 countries through an international network. Erario is equally optimistic. “Although the decline in cigarette users worldwide is a fairly consolidated fact, our activity of designing and manufacturing glue systems for various types of projects is in continuous development, and we continue to assist our customers day after day constantly,” he says.

Baumer remains focused on innovation for the tobacco sector. By creating a tobacco competence center, which was opened in October 2018, Baumer brought its expertise for the cigarette market to Milan, Italy. “The Italian team, assisted by the headquarters in Germany, has a very broad portfolio of solutions for the traditional—or commonly called high-risk—cigarette business,” he says. “These solutions are by now consolidated and range from systems for filter makers, combiners or tubes. We are strongly active in the packer machine to finish with the production of cases for cigarette packets and the end-of-line case packer. We also design and customize dedicated systems and dedicated solutions for our customers every day.”

H.B. Fuller’s focus, meanwhile, is to create a global portfolio of innovative adhesives and systems that significantly reduce costs, improve efficiency and make products more sustainable. Recently, the company introduced Swifttherm 6200, a hot melt for all filter types. According to H.B. Fuller, Swifttherm 6200 delivers a superior bond strength, both during production and storage, increasing productivity while reducing the share of rejects. With a long “open time” and short setting time, it can be used for conventional and new-generation products, reducing complexity. According to H.B. Fuller, customers can reduce the number of filter hot melts to just one adhesive.

The company has also launched a solution for bonding untreated filmic carton board, such as Transmet, laminated and metallized boards. Ipacoll 2948 is a water-based adhesive.

With the Ipacoll 2600 series, the company has developed a range of high-performance tipping adhesives that allow customers to simplify their adhesive needs across their entire manufacturing network, Akbasli says.

Catering to a Highly Regulated Market

Regulatory compliance remains among the most important requirements. “The tobacco industry is one of the more highly regulated markets in which H.B. Fuller operates,” says Akbasli. “We have specialized industry expertise and know-how to keep products compliant with manufacturing requisites and regulation that, as you can imagine, are completely different in each market and each region,” she says.

“To navigate the complex world of regulatory matters, we have dedicated regional regulatory teams within our regulatory global function that work directly with industry associations, governmental agencies and our own technical and sales units to make sure we are engineering the right products for today and the future. The specific adhesive performance requirements can vary from customer to customer, but in general they require a consistent adhesive performance that enables their production to run seamlessly without any adhesive-related downtime. That consistent performance includes clean application through the adhesive equipment and profile-optimized adhesive setting for the range of machine speeds and substrates, secure adhesion both during production and in the hands of the consumer.”

Sustainability has become another driver in the tobacco industry. “We have seen a rise in demand for greener products as regulations around the handling of chemicals have become tighter, especially in Europe,” she says. “Around the world, natural-based articles are in high demand, and it’s a trend set to continue apace. The global tobacco market changed dramatically over the last ten years, and we expect this pace of change to continue. Adhesives are a key enabler for our customers to produce more sustainable products, whether they are natural/bio-based, compostable or recyclable.”

H.B. Fuller has multiple projects involving top scientists designing and engineering technologies that contribute to the circular economy and help customers meet their own sustainability goals. Projects range from formulating adhesives using bio-sourced raw materials to developing new, natural and responsible sourced adhesive raw materials. “We already have an advanced solution that enables our tobacco customers to significantly reduce the carbon footprint of their production facilities,” says Akbasli. “It requires them to work in a slightly different way, but the customers partnering with H.B. Fuller are excited to see what they can achieve in 2022 and beyond.”

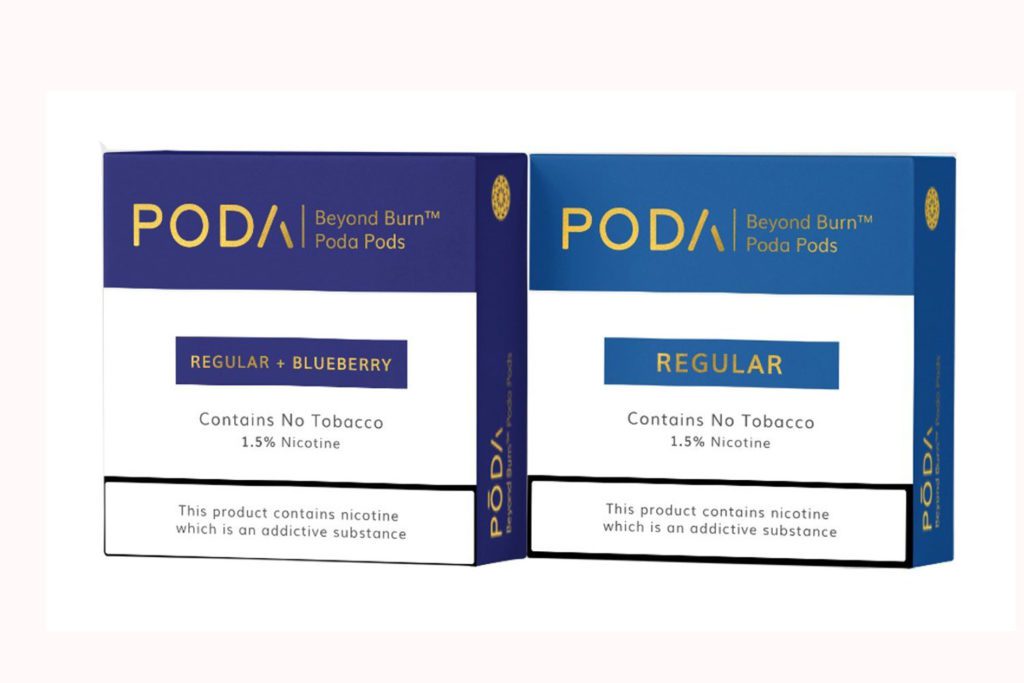

Dedicated Solutions for NGPs

Next-generation products (NGPs), too, are high on the agenda of adhesives and adhesive application manufacturers. “Baumer hhs has been active in the New Generation Project (low-risk cigarette) market since its inception,” explains Erario. The company has also been exploring opportunities beyond tobacco. “We also have ready-made solutions for the new—even if it’s not really ‘new’—cannabis market or even pre-roll hemp. Our knowledge in terms of contact and noncontact glue application, the knowledge of world players will help our consolidated customers and new ones in this new business.”

For the new generations of cigarettes and the packages that contain them, Baumer is drawing on its know-how of the traditional cigarette market. “We have developed dedicated solutions and at the same time increased the performance of our products and solutions to ensure maximum reliability for our customers’ machines,” says Erario. “Today, this is recognized by having systems on the market that guarantee flexibility, sturdiness and ease of use, our customers say.”

H.B. Fuller says it has a market-proven range to produce consumables for all NGPs, regardless of brand. The key differences in the production of heat sticks for heated-tobacco devices involve the design of the stick, the filter, the materials used to manufacture the stick and the mode of operation, explains Akbasli.

“The filters are designed differently using new materials, and they have a more complex construction,” she says. “With this comes new and additional issues related to adhesive performance requirements. Higher grammage papers used are stiffer in nature, the nonwrap acetate filter material is harder to bond and the smaller length used presents process challenges. All this combined requires the use of an adhesive with higher wet tack and a stronger setting bond.

“Overall, the heat stick and filter consist of more parts versus a conventional cigarette. Many of these parts have a reduced level of elasticity when compared to conventional cigarettes, and this means they are harder to form into the desired shape for the stick during production. This has been a challenge for suppliers and NGP producers to overcome through extensive collaboration that required the design of new machines, materials and adhesives. And lastly, the mode of operation for these products is different. They are only heated and not burned, posing different challenges for the adhesive to remain functional whilst the cigarette stick is being used.”