Cigarette manufacturers are offering alternatives to smokers left in the cold by the EU menthol ban.

By Stefanie Rossel

As the Covid-19 shutdown left many retailers unable to sell off their noncompliant products ahead of the EU menthol ban, tobacco industry representatives pleaded for an extension of the deadline to no avail: On May 20, article 7 of the Tobacco Product Directive (TPD2) entered into force. Since then, sales of cigarettes with “characterizing” flavors other than tobacco have been prohibited throughout the EU. The ban, which predominantly affects the menthol cigarette category, has ended sales of cigarettes with menthol capsules, click on, click and roll, crushball or dual menthol cigarettes. Vending hand-rolling tobacco with mentholated filters or papers is also illegal if they are supplied together. Exempted from the ban are menthol-flavored e-liquids for vapor products, separately available mentholated smoking accessories, menthol-flavored oral nicotine pouches and cigarillos. Outside of Germany, mentholated consumables for heated tobacco products (HTP) also continue to be legal.

The ban has eliminated an entire class of cigarettes throughout the continent. Although menthol is a far smaller business in the EU than it is in the U.S., where it accounts for roughly one-third of all cigarette sales, its prohibition touches around 8 million adult smokers, according to the most recent Eurobarometer report (from 2017) on attitudes of Europeans toward tobacco and electronic cigarettes. The report finds that menthol cigarette consumption varies significantly throughout the common market, with the products being most popular in Finland (24 percent), Denmark (20 percent) and the U.K. (18 percent) and representing a small proportion of the markets in Slovenia, Cyprus and Greece with 2 percent each. Euromonitor International estimates that the category generates $11 billion in sales in Western Europe.

A matter of taste

The question is how the millions of menthol smokers will respond when they can’t get their favorite fix anymore. Are they going to quit smoking altogether, as the European Commission hopes? Will they embrace regular cigarettes, resort to mentholated tobacco products that remain legal or switch to reduced-risk products (RRPs)?

“It is still too early to predict what current menthol smokers will do once their preferred products disappear from shelves,” says Femi Namfua, corporate media relations director at Japan Tobacco International (JTI). “The EU gave menthol smokers a six-year transition period to switch to other products. We now have to wait and see how smokers will react. We hope the menthol ban in the EU won’t lead smokers to the illegal trade as this will completely defeat the purpose of the ban—something we warned regulators about during the proposal phase of the new regulation.”

Eric Sensi-Minautier, head of British American Tobacco’s (BAT) EU office, shares this view. “It’s the million-dollar question,” he says. “I believe they will resort to looking for other possibilities available. That’s why it is essential that we are able to offer a greater choice of enjoyable and less risky products.”

Earlier this year, JTI surveyed more than 350 retailers in the U.K., a £11 billion ($13.67 billion) cigarette market of which JTI and Imperial Brands jointly hold an 80 percent share. Data that became available after the 2017 Eurobarometer report suggests that around a quarter of the U.K. market, or $3.42 billion, consists of mentholated cigarettes. Of the surveyed retailers, 25 percent believed that former menthol smokers would remain brand loyal within the ready-made cigarette (RMC) category, 19 percent thought they would switch to roll-your-own tobacco and 45 percent were confident that their customers would switch to vaping or other RRPs. Eleven percent expected previous menthol users to leave the category altogether.

Imperial Brands is enticing former menthol smokers to embrace its vapor products.

Photos: Imperial Brands

Ban sparks innovation

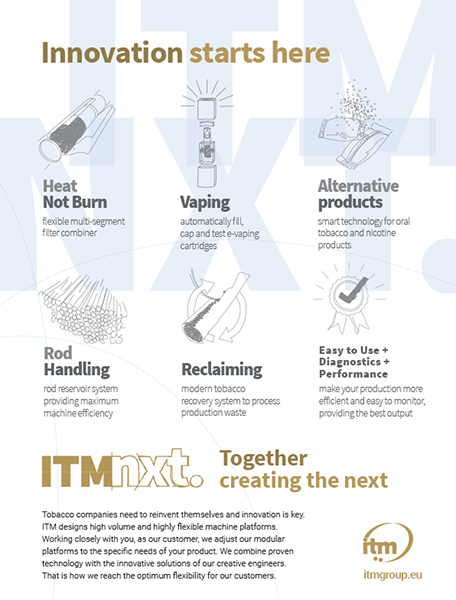

To meet all possible consumer preferences, cigarette manufacturers in recent months have become creative in their efforts to provide former menthol smokers with the widest possible range of products, including RRPs.

“Menthol cigarettes account for a significant portion of the European market, so the removal of these products from shops last month means a number of smokers will be seeking to make alternative product choices,” says Simon Evans, group media and online communications manager at Imperial Brands. “It’s important that we provide a range of options at such a time of significant consumer ‘churn.’ Our Myblu vaping product is available in menthol and other flavored varieties, giving extra impetus for smokers to transition away from cigarettes.”

“But we also understand that many menthol smokers will decide to continue to smoke and so we also focus on providing an evolving portfolio of products in line with their expectations,” says Evans. “Rizla Flavour Cards are flavor-infused sheets of card that can fit inside a pack of cigarettes. When left in the pack for at least an hour, the contents will take on the flavor of the card. Menthol and mint varieties are available. Rizla menthol filter tips are also available for consumers of rolling tobacco.”

Aroma cards have been around from other suppliers for some time, for example from Frizc. For the flavoring of loose tobacco, companies like MacBaren offer ampoules with liquid menthol aroma.

BAT, which is preparing for a future that is likely to be in noncombustible nicotine products (see “Beyond Tobacco,” Tobacco Reporter, May 2020), has been extending its vapor product portfolio to cater to former menthol smokers’ needs. In early May, the company introduced a range of new menthol e-liquid flavors and limited-edition starter kits for its Vype brand in the U.K. “Our strategy is to accompany smokers to move to less risky products,” Sensi-Minautier points out. “The entry into force of the EU menthol ban is a good moment for this.”

According to the company, the new range of e-liquids now closely mirrors the experience of smoking a menthol cigarette, with new blends, an innovative tube filter and new formats across the range. BAT has also innovated its Pall Mall, Vogue and Rothmans brands to offer former menthol smokers attractive, nonmenthol cigarettes.

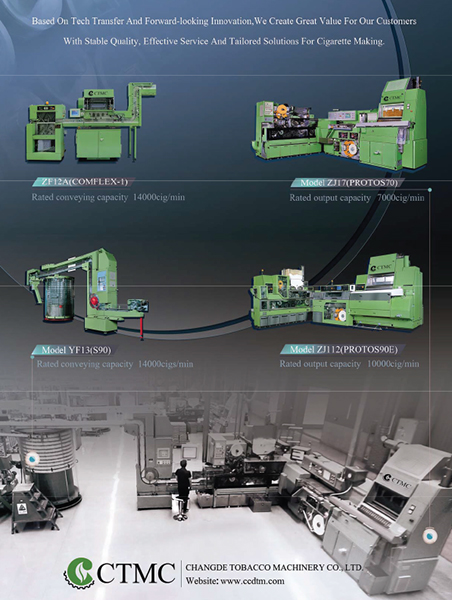

Advertisement

Providing more choice

In March, JTI launched several alternative products with new tobacco blends in the U.K. Its New Dual range, which is available in the Sterling, Benson & Hedges and Sovereign brands, provides smokers with new, distinctive tobacco blends, replacing the company’s former menthol capsule cigarettes. The same blend will also be used for the “green” product variants of the Sterling, Benson & Hedges and Berkeley “New Superkings” ranges. As long as their products do not contain menthol, retailers are still allowed to sell cigarettes with names that were previously used to describe a menthol product, such as “green.”

For all those who can’t do without their hint of mint, JTI in early February introduced a cigarette-sized menthol cigar, the Sterling Dual Capsule cigarillo, in the U.K. The product is marketed under the same name as one of JTI’s cigarette brands but is exempt from the ban because it is wrapped in tobacco leaf rather than paper. As its name implies, its filter contains a mentholated capsule, which smokers can click to release a peppermint flavor. Being a cigarillo, it sells at half the price of regular cigarettes.

The company also broadened its RRP portfolio, introducing a variety of new menthol flavors for its Logic e-cigarette brand and its Ploom tobacco vapor products, and outside of RRP, its Nordic Spirit nicotine pouches.

Philip Morris International (PMI) in March added a menthol kit to its IQOS heat-not-burn product comprising an IQOS 2.4 device and two packs of mentholated heat sticks. According to the company, 51 percent of menthol smokers would switch to IQOS when their preferred menthol smoke was no longer available, betterretailing.com reported.

Despite the long transition period—the ban on menthol was announced in 2016, with the introduction of the TPD2—awareness of the new rules remained remarkably low among retailers and consumers alike as the deadline approached. In another JTI survey, carried out one week before the ban took effect, more than half (52 percent) of participating U.K. retailers said they expected adult smokers to remain brand loyal within the RMC category; 31 percent believed their customers would switch to vaping or other reduced-risk products; 11 percent think they will switch to roll-your-own (RYO); and just 6 percent expect adult smokers to quit the category altogether. The results show a significant shift in thinking compared to JTI’s previous survey, with more retailers now believing that their customers will remain brand loyal within the RMC category and fewer assuming smokers will switch to vaping, RYO or quit.

Days before the ban entered into force, another poll, conducted for smokers advocacy group Forest, found that the lack of awareness of the ban also extended to consumers: Almost 40 percent of the more than 2,000 U.K. smokers surveyed were oblivious to the new rules. Only 16 percent believed that the ban would lead to a reduction in smoking prevalence whereas 46 percent of smokers thought that it would lead to an increase in illicit trade.

To educate stakeholders, leading tobacco companies created dedicated websites, which also included information about alternatives to menthol cigarettes and companies’ buyback schemes for unsold menthol cigarettes.

Unwanted side effects

The justification for banning menthol cigarettes is that the minty taste masks the harshness of the inhaled tobacco smoke, which might make it easier for nonsmokers, including young people, to take up smoking.

The tobacco industry has long disputed that line of reasoning. “Peer pressure and parental influence are the main reasons for starting to smoke, according to studies, not menthol cigarettes,” says Namfua. “Study results do not support the claim that menthol smokers start smoking at a younger age. There is no sufficient evidence to support the claim that a prohibition of menthol tobacco products will affect smoking rates as campaigners suggest. Such a ban is therefore an unjustified restriction on adult consumer choice and sets a dangerous precedent for other products beyond the tobacco category.”

“Young people don’t start smoking because of menthol,” echoes Sensi-Minautier. “We do not believe the available science supports the idea that a menthol ban will reduce youth smoking or address the health impact of smoking more generally. Personally, I don’t believe that it will have more of an impact on smoking rates than plain packaging, which has had no effect.”

Canada, which prohibited menthol cigarettes in October 2017, provides a cautionary tale. Several of the country’s provinces already had menthol bans in place at the time of the nationwide rule. A study published this February by the National Bureau of Economic Research found that the provincial menthol bans simply increased nonmenthol cigarette smoking among youths, leaving overall youth smoking rates unchanged.

While the menthol ban may not achieve the desired reduction in EU youth smoking, it may very well bring about unintended consequences. “We now have to wait and see how smokers will react, but based on previous bans, what we often see is a coinciding increase in illegal trade and a decrease in tax revenues,” Namfua points out. “Government revenues are jeopardized in case of a ban in any market with mentholated tobacco products, especially in places where a large part of existing smokers choose them, like Poland, for example, as they may look to illegal channels to buy their preferred flavors in [the] future. U.S. law enforcement agencies are publicly opposing a menthol ban due to worries of an increase in organized crime, which remains an important concern.”

If smokers of mentholated cigarettes switch to illegal channels, the impact on government revenues would be substantial. “Studies show that up to 25 percent of menthol smokers would buy cigarettes from the illegal market instead, meaning governments would lose millions,” says Namfua.

In Europe, he says, criminal gangs started taking advantage of the menthol ban even before it was implemented. U.K. law enforcement agencies began finding packs of counterfeit menthol cigarettes as early as October 2019—seven months before the ban.

“Any prohibition of a product may be a driver of illicit trade, but the situation might be more complex,” cautions Sensi-Minautier. “We need to be careful because we don’t know yet if current consumers of menthol cigarettes will consider menthol to be so important to them that they find an illicit source. It would also be interesting to see whether the criminal gangs will seize this opportunity to diversify.”