To lower the health and economic burden of smoking, lawmakers should incorporate tobacco harm reduction into their policies.

By Stefanie Rossel

The figures are staggering. Smoking cost the world economy an estimated $1.85 trillion, or about 1.8 percent of global gross domestic product (GDP), in 2012, according to a monograph published by the World Health Organization and the U.S. National Cancer Institute in 2016.

The authors distinguish between direct and indirect costs. Direct costs, which include both healthcare expenses, such as physician fees or medical supplies, and nonhealthcare costs, such as transportation, were approximately $467.3 billion, representing 6.5 percent of global health expenditures, or 0.5 percent of global GDP. Indirect costs, which include the value of productivity and lives lost due to tobacco-related diseases, were an estimated $446.3 billion for disability and $938.6 billion for mortality.

Low-income and middle-income countries (LMICs) account for almost 40 percent of the expenses incurred globally due to tobacco use, with direct costs representing up to 4 percent of total health spending in these countries. The total economic costs of smoking in LMICs ranged from 1.1 percent to 1.7 percent of GDP in the countries investigated in the report compared with an estimated 2.4 percent in the Americas and 2.5 percent in Europe.

Some of the data in the monograph dates back to the late 1990s, and it is likely that costs have increased since its publication. While some research released since the publication of the paper suggested that reductions in smoking prevalence would translate into lower healthcare costs quite quickly, these papers focused primarily on the healthcare systems of large, wealthy and technologically advanced societies rather than LMICs, where 80 percent of the world’s smokers live.

People in LMICs are significantly more likely to die from noncommunicable diseases (NCDs), which include cardiovascular and chronic respiratory diseases, cancer and diabetes, along with mental and neurological conditions. According to the WHO’s website, NCDs account for the deaths of 16 million people prematurely, i.e., before their 70th birthday, worldwide each year.

Tobacco use represents the leading risk factor for NCDs, ahead of other risk factors such as air pollution, excess sodium intake, alcohol abuse or sedentary lifestyles. According to WHO data, tobacco currently accounts for 8.2 million deaths per year, including the effects of exposure to secondhand smoke, a figure that is projected to increase over the coming years.

However, the WHO is far from achieving the U.N. Sustainable Development Goal of reducing premature deaths from NCDs by one-third by 2030. Depending on the source (and even the WHO’s numbers are inconsistent here), there are currently between 1.1 billion and 1.3 billion smokers in the world, and the figure is likely to rise, due in part to population growth.

One of the major weaknesses of prevention is that the benefits take a long time to materialize.

Focus on Prevention

“When governments and government agencies lie about the health costs of vaping relative to smoking, they are betraying the trust of the public.”

According to critics, the WHO’s established tobacco control measures are insufficient to achieve the desired reductions in smoking and the associated burden on healthcare systems. To accelerate progress, policymakers need to fundamentally change their approach, argues Andrzej M. Fal, president of the Polish Society for Public Health, who spoke at the Warsaw Global Forum on Nicotine in June.

“If we enforce policies that reduce the risk of smoking now, there will be a significant reduction in cancer in 15 [years] to 20 years,” Fal pointed out. Because chronic diseases account for 90 percent of premature deaths, he argued, investing in their prevention is more cost-effective than treatment. The WHO itself recommends prevention as a response to noncommunicable diseases. Fal cited calculations from the global health body showing that every dollar invested in smoking prevention saves $7.43 down the road.

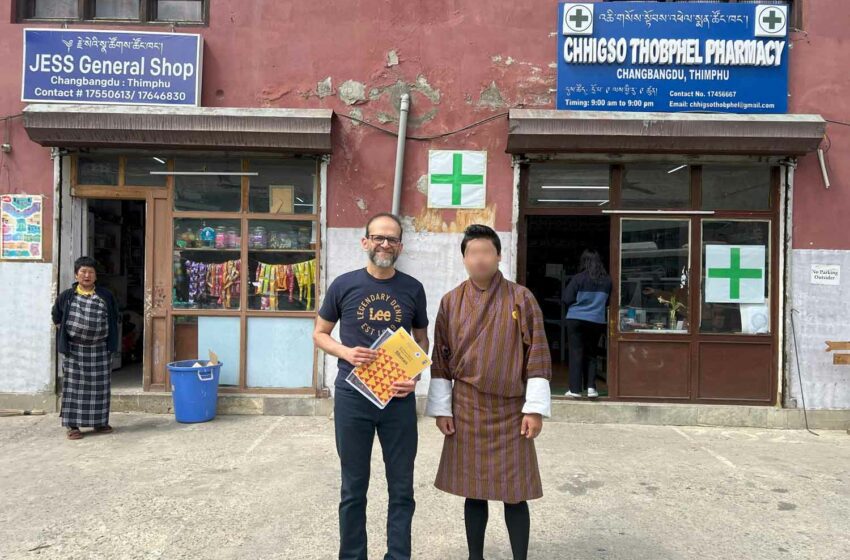

Based on such considerations, Fal urges authorities to place greater emphasis on prevention and tobacco harm reduction. In 2023, the Polish Parliament analysis office asked Fal to prepare an analysis of the state of the tobacco “epidemic” in Poland. Fal and his co-authors concluded that the country lost 250,000 years of life as a result of tobacco consumption.

Education about health, Fal suggested, should begin in kindergarten. People who are already ill and refuse to quit smoking should be incentivized to minimalize their risk using less hazardous nicotine-delivery alternatives. “If someone is already seriously ill,” Fal explained, “they can still achieve a better quality of life, live longer, and cost the system less,” he said.

Fal proposed that each country launch at least one prevention clinic, which should be accessible without referral and would offer access to anti-smoking therapy, nicotine-replacement pharmacotherapy and harm reduction products. The clinics should also be responsible for regional health prevention programs and smoking information campaigns.

Governments, he suggested, should set tobacco tax rates based on the relative harm of each product category, following the principle of “less harm, less tax.” Taxes on cigarettes—the most harmful tools for tobacco consumption—should rise “radically but progressively,” said Fal, who also called for publicly funded and supervised studies assessing the efficacy, safety and harm reduction in cases where the existing evidence was insufficient.

One of the major weaknesses of prevention, however, is that the benefits take a long time to materialize. In a U.S. study analyzing the relationship between cigarette sales and lung cancer deaths, for example, it took 20 years for the first measures taken to curb tobacco consumption to show up in lower lung cancer death statistics. That time frame is too long for many lawmakers. “Politicians are not interested in investing in prevention as its benefits are seen long after they have left the government,” said Fal.

Progress is also obstructed by conflicts of interest. In 2018, he noted, Poland’s tobacco-related health expenditures plus productivity loss were between PLN7 billion ($1.71 billion) and PLZ8 billion in 2018, whereas excise and VAT income from cigarettes amounted to PLN23.5 billion.

Every dollar invested in smoking prevention saves $7.43 down the road.

Myopic MPs

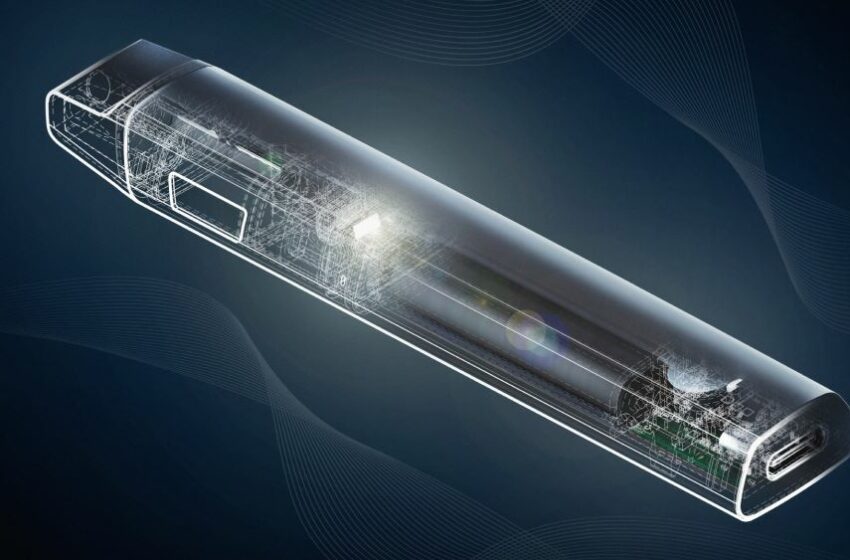

All too often, politicians are uninterested in considering the potential unintended consequences of their decisions. For example, Australia’s rules requiring vapers to get a medical prescription and banning imports of disposable e-cigarettes have caused the illicit market to flourish. Ninety-two percent of Australian vapers currently source their vapes from the black market, exposing them to unrelated products. More than 70 tobacco shops have gone up in flames since Health Minister Mark Butler started his crackdown on vapes. Police suspect some of the attacks are carried out by criminal groups as retaliations against store owners who refuse to stock their black market products.

“Australia tends to pursue harm minimization policies in most areas—except in tobacco and nicotine consumption,” said Sinclair Davidson, professor of institutional economics at RMIT University, Melbourne. “Here, Australia pursues the most socially harmful policies that the so-called public health lobby can dream up. The costs this policy’s short-sightedness imposes on the economy are likely to be large but hidden or indirect. For example, when cigarettes are stolen from convenience stores, this results in insurance costs being increased on those stores and prices being increased for all consumers.

“Similarly, when criminal profits are increased, criminal behavior in the economy increases. When criminal behavior increases, police budgets increase, resulting in higher taxes for all citizens and higher levels of criminal behavior. We are all victims of crime and criminal behavior—except, of course, the public health lobby, who have built careers off their policy work, and politicians and law enforcement agencies who get expanded budgets and powers as a result of poor policy. It is a vicious cycle of ‘Baptists and bootleggers’ who benefit while the rest of society suffers.”

Meanwhile, the decline in tobacco tax revenue even as smoking rates have stabilized suggests that people are still smoking—they’re just not smoking legal cigarettes. “The challenges are twofold,” said Davidson. “Government itself has become addicted to tobacco excise revenue, and that source of revenue has become unreliable. The subsidy from smokers to the rest of the population has been captured by criminals. Criminality imposes huge costs on society. This occurs through the normalization of violence and the misallocation of resources from legal activity to illegal activity. Furthermore, criminality has a corrupting influence on law enforcement activities. Poor policy corrodes civil society by undermining public trust in public institutions. When governments and government agencies lie about the health costs of vaping relative to smoking, they are betraying the trust of the public and undermining their moral worth in society.”

By contrast, Sweden’s success in reducing smoking rates by accommodating snus is a public health success story, according to Davidson. Since 2008, Sweden has slashed its smoking rates from 15 percent to 5.6 percent, according to Smoke Free Sweden. The nation’s smoking prevalence is expected to dip below 5 percent this year, making it the first country to achieve “smoke-free” status as defined by the WHO.

Sweden’s incidence of cancer is 41 percent lower than in the rest of the EU, corresponding to a 38 percent lower level of total cancer deaths. The country has a 39.6 percent lower rate of death of all tobacco-related diseases compared to the EU average. “I don’t know to what extent Australian consumers are familiar with snus and what the uptake would be—but the principle remains. Low(er) risk products on the market result in consumers substituting away from the high(er) risk products,” said Davidson.