Seke opens a tobacco processing factory in Macedonia.

TR Staff Report

Facing declining cigarette sales and increasing regulatory pressures, tobacco companies around the world have been scaling back their operations and diversifying into other activities. So when a leaf merchant announces a substantial investment in its traditional line of business, the industry sits up and takes notice.

Next month, Seke will open a €6 million ($7.39 million) tobacco processing factory in Macedonia. Located near Prilep, in the heart of Macedonia’s tobacco growing region, the new facility will be able to store and process 4.5 million kg of oriental tobacco per year.

The opening is the latest step in Seke’s ambitious expansion plan in the Balkans.

Created in 1947, Seke is the Greek Cooperative Union of Tobacco Producers. Its headquarters and factories are in Xanthi, in northern Greece, an area known worldwide for its excellent-quality oriental tobacco. Today, Seke is the biggest tobacco company in Greece and the second-largest in the Balkans. It caters to multinationals, independents and local players.

At the turn of the century, Seke was a purely domestic player, according to Alexandros Kontos, the firm’s current general manager, who served as Xanthi factory director at the time. “The company was satisfied with the existing situation,” he says with a shrug. In 2000, Kontos left his position at Seke to run for public office.

Kontos was elected a member of parliament representing Xanthi prefecture. From 2004–2009 he served as minister of rural development. In this position, he looked after the interests of Greek tobacco growers during the EU negotiations on agricultural policy, among other things.

In 2010, Seke hit hard times, and the firm’s president asked Kontos to return and help the company improve its competitiveness. The tobacco industry was under attack on multiple fronts, and Greece had just been struck by the worst economic crisis in living memory. Many companies were having problems accessing finance. “Those were the most difficult years of my professional life,” recalls Kontos.

Despite the challenging economic environment, Seke formulated an ambitious growth plan that started with heavy investment in human resources. In addition to strengthening its leaf and agronomist teams, the company hired professionals in finance, exports and business development. “You need good players to make a good team,” says Kontos, emphasizing the importance of maintaining and enhancing the quality that has always characterized Seke’s work.

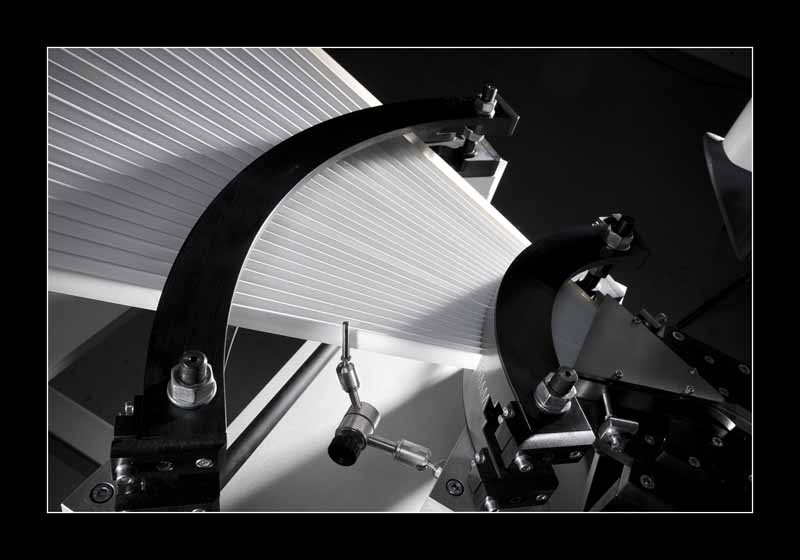

Seke spent €1.9 million ($2.32 million) to upgrade its Xanthi processing facility with the latest equipment, including a state-of-the-art Tomra laser sorter for the removal of nontobacco-related materials.

At the same time, the company decided to expand internationally. Seke’s strategic geographic location facilitated the expansion in the Balkans.

Considering Seke’s intimate knowledge of oriental tobacco, it made sense to enter other countries capable of producing that type of tobacco.

Seke set up operations in Bulgaria and Macedonia, signing contracts with farmers and hiring agronomy experts. Recently, the company started operations in Albania, too.

But Seke’s biggest splash was reserved for Macedonia, which the company views as the most sustainable source for classical oriental. According to Kontos, the country’s fertile soils, favorable climate and skilled farmers, along with its supportive regulatory environment (see sidebar), make Macedonia an ideal location for oriental tobacco production.

After receiving the applicable licenses and signing farmer contracts, Seke started operations in 2015. The company found warehouses and installed a pre-processing factory in the scenic town of Krushevo.

In 2017, the company contracted with about 3,500 growers, who produced some 2.5 million kg. This season, it expects to contract with 5,000 growers.

Initially, Seke sent the Macedonian tobaccos for final processing to Xanthi, a six-hour drive away. As volumes increased, however, it became economical to build a local factory—a move that also suited the company’s growth strategy.

Covering 11,000 square meters, the new facility is equipped with late-model presses, direct conditioning cylinders and soft dryers, among other pieces of machinery.

It will be fully operational in June and is expected to increase Seke’s local workforce from 250 to 350.

Unsurprisingly, local authorities have been keen to facilitate the company’s investment. Kontos says he has been impressed with the responsiveness of local authorities. Going forward, Seke intends to further promote Macedonian leaf qu

ality, not only by producing tobacco with desirable smoking properties but also by ensuring compliance. The company’s extensive agronomy department helps make certain that farmers use the appropriate fertilizers and crop protection agents, while minimizing environmental damage and ensuring the safety of workers.

According to Kontos, Seke’s customers have strongly supported the expansion in this country, demonstrating the industry’s continued interest in oriental tobacco. The company is eager to meet and exceed their expectations.

A sustainable source of classical oriental

It was standing room only in the theater of Prilep, Macedonia. On a chilly February evening, hundreds of farmers had come to hear agriculture minister Ljupcho Nikolovski clarify the government’s new agricultural policies. Weathered faces protruding from leather jackets took turns shouting questions about price supports, fertilizer supplies and import duties.

A beekeeper demanded protection against Ukrainian honey, which he said sells for less than his cost of production. To enthusiastic applause, another audience member asked the minister to raise crop prices by 30 percent. Tactfully rebuffing the request, Nikolovski pointed out that the government lost its authority to dictate prices years ago, when Macedonia emerged as an independent state from the Socialist Federal Republic of Yugoslavia.

Most questions, however, focused on Macedonia’s new tobacco law, which is set to take effect in the upcoming growing season. Eager to retain farmers and stimulate the production of quality leaf, the government is introducing new subsidies. Instead of receiving a flat mkd60 ($1.21) per kilogram, farmers will from now on be rewarded for higher qualities. Under the new system, grade 1 tobacco will attract mkd80; grade 2, mkd70; while grades 3 through 6 will continue receiving mkd60 per kilogram.

According to Jane Stankoski, acting manager of the State Agricultural Inspectorate, the new law builds upon an already solid legal framework for tobacco. If you want a tobacco trading license, for example, you need not only an agronomist, a processing line and a warehouse, but you must also prove that you have sufficient funds to pay your farmers. Growers, in turn, must substantiate to the government their land holdings; they cannot contract tobacco from land that they do not own. The objective is to guarantee a fair and stable trading environment for all stakeholders.

The rules demonstrate how seriously Macedonia takes its tobacco sector. At a time when most governments are distancing themselves from tobacco—witness, for example, the EU’s “decoupling” of tobacco subsidies—authorities in Skopje are strengthening their commitment to the industry.

Part of that has to do with tradition. Tobacco has a long history in Macedonia, dating to the time of the Ottoman Empire. The country has a near-perfect mix of soils, climate and farming skills for the golden leaf. “There is a true tobacco culture here,” marvels Manolis Kazantzidis, planning and business development director at Seke of Greece. Like their government, farmers in Macedonia are serious about tobacco, he says, noting that this is not always the case in other origins.

During the Yugoslav period, the tobacco industry was run by the state. After the federation collapsed in the early 1990s, the multinationals moved in. Today, Macedonia is home to two cigarette factories—one operated by Philip Morris International and one by Imperial Brands—and a whopping 10 leaf merchants. The renowned Scientific Tobacco Institute of Prilep—the oldest in the Balkans—supplies farmers with certified seeds and researches ways to promote plant health, among other tasks.

But the country’s positive attitude toward tobacco is driven also by economic realities. Generating some $124 million per year, tobacco is Macedonia’s leading agricultural export. The crop provides a livelihood to some 30,000 farm families and thousands more in supporting industries. Those are significant numbers in a country with a population of less than 2 million. What’s more, the net returns of tobacco growing are relatively high in Macedonia; according to Stankoski, the gap between earnings from tobacco and earnings from other activities is bigger than it is in competing tobacco growing countries.

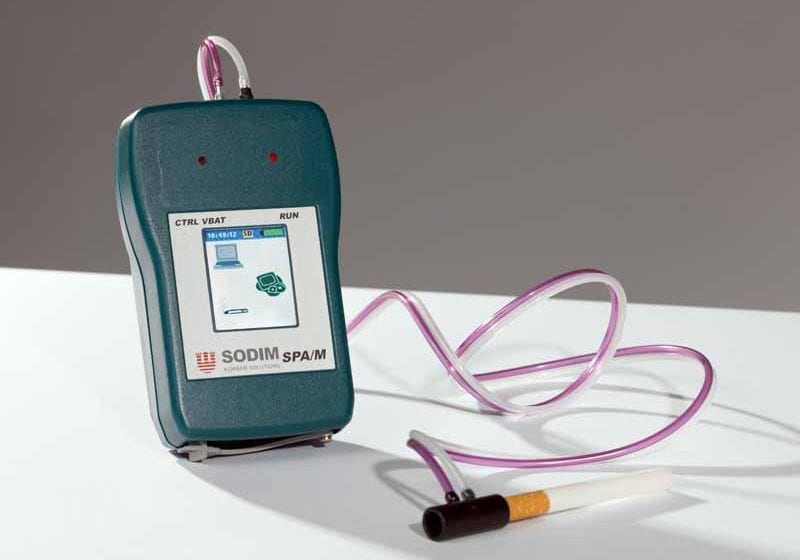

Macedonia is fortunate in that it produces a style—classical oriental—that remains in demand even as global cigarettes sales have slumped. Classical oriental is an essential ingredient in the still popular American-blend cigarettes and the emerging heat-not-burn category. According to local industry representatives, the country’s type of tobacco is used by all major players. Also, as regulators around the world restrict the use of artificial tobacco flavorings, tobacco companies are likely to seek out more tobaccos with strong flavors of their own. Classical oriental fits the bill.

Only a handful of countries—the other ones are Greece, Turkey and Bulgaria—are capable of growing true classical oriental. With annual production averaging around 25 million kg, Macedonia is second to only Turkey in terms of absolute output. When measured against the size of its population and economy, however, the role of tobacco is much greater in Macedonia than it is in neighboring countries. Attempts to produce the leaf outside of the traditional sourcing areas have been unsuccessful. Reflecting the strong demand and limited supply, this year’s green prices were up by 10 percent over those of last year in Macedonia.

For the reasons outlined above, industry representatives view Macedonia as a sustainable source of classical oriental. Nonetheless, even here, there is concern about the future. At 45, the average Macedonian tobacco farmer is younger than his counterparts in Greece or Turkey, but he’s not exactly a spring chicken, either. Many youngsters view farming as unfashionable. They’d rather wait tables in the city than toil in the countryside. At the same time, health advocates are pushing farmers to embrace other crops.

The tobacco scientific community faces a similar problem. One of the Tobacco Institute’s big challenges, according to senior research fellow Biljana Gveroska, is recruiting young scientists.

Stankoski suspects young people would feel differently if they realized how lucrative tobacco farming can be in Macedonia. The combination of good prices and a guaranteed market, he says, is unrivaled. Part of the solution, he believes, lies in better communication. Another part could come from efforts to make tobacco farming easier. Growing oriental is a notoriously laborious undertaking, and leaf merchants have been looking into ways to mechanize the job. The new tobacco law, too, should help—not only by strengthening the legal framework but also by ensuring that good farmers are well-rewarded.—Taco Tuinstra