U.S. Tobacco Cooperative (USTC) has begun planning an exit from Chapter 11 bankruptcy later this summer. The cooperative originally filed for protection in July 2021 to meet contractual obligations to its member growers while the company faced uncertainty presented by an ongoing class-action lawsuit.

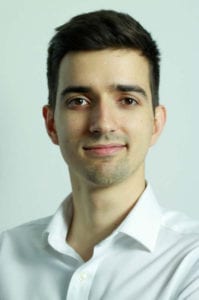

“On February 2, after 17 years of litigation, we were able to reach economic terms of a settlement with the Lewis Class,” said USTC CEO Oscar J. House. “As we await final approval from the court this summer, we are beginning to prepare our exit from bankruptcy and continue providing the exceptional service and quality products our organization is known for across the globe.”

USTC originally filed for protection in federal bankruptcy court to satisfy obligations to its 550-plus member-growers, 200-plus employees, suppliers and customers. The settlement and plan of reorganization will allow the cooperative to honor its commitments worldwide and emerge from bankruptcy well positioned to serve its member-growers. Details of the agreement will be provided in the ordinary course of obtaining formal court approval of the settlement and USTC’s plan of reorganization.

“USTC is healthy and set for a sustainable, successful future,” continued House. “Throughout the bankruptcy process we have fulfilled all obligations to all stakeholders: our customers, grower-members, vendors and employees. Going forward we will continue to do so, stronger than ever.”