The prospects for tobacco packaging remain bright despite stagnating cigarette sales.

By George Gay

A recent Fortune Business Insights report predicted that the turnover of the global tobacco and nicotine packaging business would grow from the $16.15 billion of 2019 to $20.45 billion by 2027. This seems like a healthy increase given what we are often led to believe is the declining state of the business, at least the overwhelmingly dominant part of it that is made up of sales of traditional cigarettes.

Given this, Tobacco Reporter asked Paula Birch, global sales director of Parkside Flexibles, whether she believed the sector of the tobacco and nicotine packaging business that Parkside operated in would grow to this extent, and she kicked off her emailed reply by providing some context to the growth figures.

As was mentioned by Fortune Business Insights, the value of the tobacco packaging market was predicted to grow by about 27 percent during the next six years, she said. Additionally, research by British American Tobacco had found that more than 19 percent of the world’s population comprised smokers who consumed more than 5.3 trillion cigarettes annually across a global cigarette market worth about $700 billion, a figure that rose to $814 billion annually when other tobacco and nicotine products were included. It was also the case, though, that cigarette sales had fallen by 17 percent since 2010, so the high and increasing figures for the value of sales had been down to retail prices, which, at the same time, had increased by 91 percent, according to figures by the U.K. Office for National Statistics.

“As prices have risen, consumers have increasingly demanded value for money and greater premiumization to ensure they are getting what they pay for,” said Birch. “The key to achieving these two aspects is via enhanced barrier performance, which provides improved tobacco quality, freshness and extended shelf life, all of which can be achieved with flexible packaging. By using flexible solutions for inner liners, pack wraps and pouches, brands can provide consumers with the superior quality they are seeking.

“As a result, we are now seeing the emergence of flexible packaging as the solution of choice for tobacco brands in Eastern and Western markets due to its greater ability to protect, preserve and present throughout the supply chain from manufacture to supermarket shelf. For tobacco brands, flexible packaging offers greater flexibility and cost-effectiveness in production when compared to other popular solutions, such as cardboard. At Parkside, we develop flexible packaging solutions that offer superb barrier performance to prevent product deterioration and aroma transmission and inhibit the growth of bacteria within the pack, thus ensuring premium freshness and quality of tobacco products.

“The benefits of flexible packaging for the consumer and brand mean we feel confident that over the next decade, this packaging format for tobacco will grow at a similar double-digit rate in line with the overall tobacco packaging market.”

As prices have risen, consumers have increasingly demanded value for money.

JPaula Birch, global sales director, Parkside Flexibles

Growing populations and hectic lifestyles

One question that arises out of this is whether the growth in tobacco and nicotine packaging turnover will be driven mainly by demand in particular countries and regions or be a worldwide trend. Consumption patterns, at least up until the Covid-19 pandemic struck, would seem to suggest that growth would have to be fueled by developing countries, but is there more to it than volume consumption?

The U.S. Centers for Disease Control and Prevention stated that between 2005 and 2015, the percentage of adults smoking fell worldwide, said Birch. Despite this, the global tobacco packaging market continued to grow because, while the overall percentage of people smoking had reduced, global populations continued to rise, resulting in higher numbers of people consuming the product. And, as mentioned previously, packaging company turnover was increasing as a result of their meeting the rise in consumer expectations about product quality.

“The modern-day lifestyle in many countries—with increased workloads, hectic schedules and, indeed, the Covid-19 pandemic—has led to a significant increase in tobacco consumption among professionals and those with stressful professions,” said Birch. “We expect to see the Asia-Pacific region experience the fastest growth in tobacco packaging turnover due to this combination of population growth and working lifestyle. We also anticipate continued growth across Europe and the U.S. for the same reasons.

“Interestingly, growth in the flexible packaging format does not rely solely on consumption patterns. Due to the versatility of the format across pack wraps, inner liners and pouches to name a few, the substitution of metal, card and paperboard continues to drive market growth.”

Platform for promotion

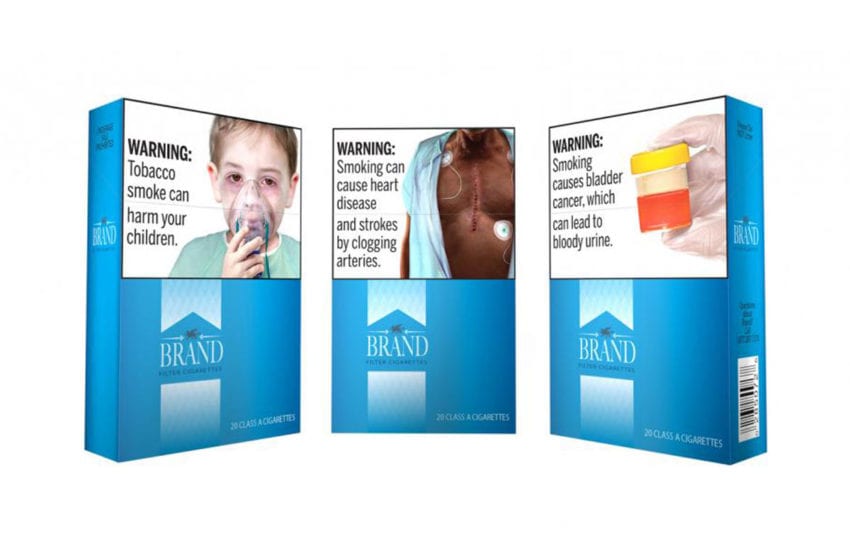

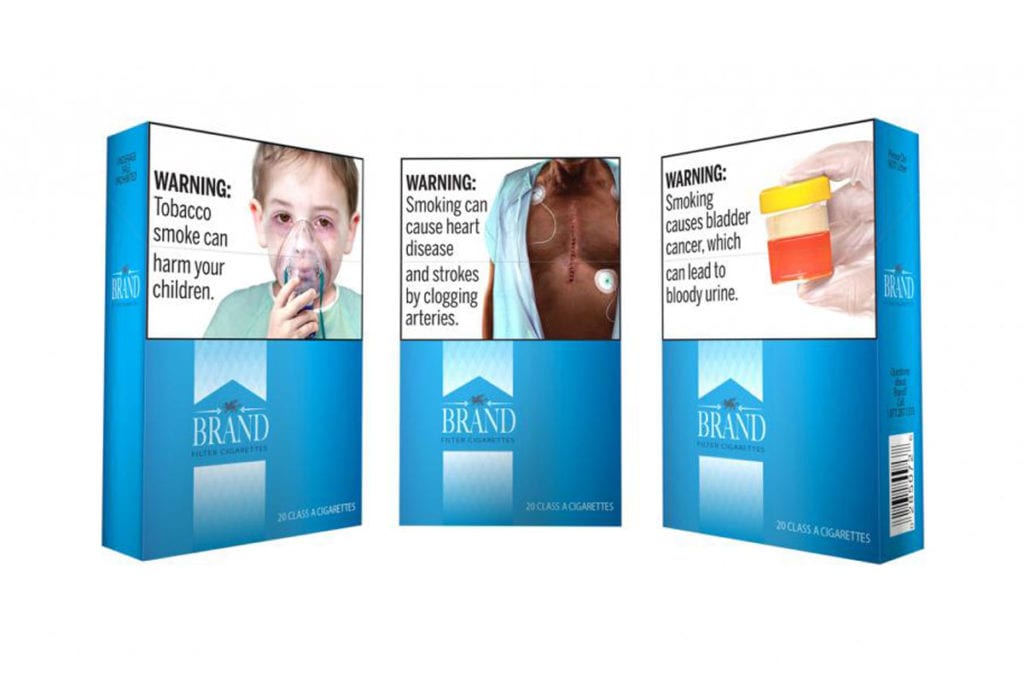

Even with standardized tobacco packaging being introduced in many countries, the authors of the Insights report seem to believe there is still a part that packaging can play in product promotion. So Tobacco Reporter asked whether Birch believed this to be the case.

“Absolutely,” she said. “Although brands must adhere to strict packaging guidelines in terms of packaging standardization in many countries, there are still significant opportunities to utilize the right packaging to promote a particular product. These restrictions can be challenging when competing with lower-risk products like vapes that are not constrained by packaging design laws as stringent as those for standard tobacco packaging.

“It is vital in the modern market space that brands market and communicate their products through unique and innovative promotional methods. In particular, the opening and reclosing feature can be differentiated, the use of tactile or premium finishes on the inside of the pack, and integration of novel communications and graphics within the pack can all be leveraged. Tactile packaging and intricate design work like embossing can help to convey a premium quality. This is often seen in the premium spirits market, where bottles are placed in intricately designed boxes to create a sense of luxury, generating a consumer sensory experience beyond the purely visual.

“Sustainability is also a feature that consumers consider when making their purchases, so brands can use this to stand out from the crowd. Laminate structures of compostable films can be used to produce the pouches widely used by the roll-your-own tobacco consumer, and they comprise a viable, environmentally friendly alternative to other materials. At Parkside, we have created fully accredited flexible packaging pouches that compost both at home and in industrial composting environments. Accredited to EN13432 and Vincotte OK Home Compost regulations, the compostable OTP pouch enables brands to demonstrate their sustainability commitment.”

Finally, Tobacco Reporter asked Birch the question that, currently, no interview can leave out: How has the Covid-19 pandemic affected Parkside’s business?

“The last year has been extremely challenging for all businesses,” she said. “Demand has been volatile, and there have been various supply chain challenges, which we have successfully navigated.

“At Parkside, our primary focus is on the health, safety and well-being of our employees and their families as well as our customers, suppliers and the communities we operate in. We implemented a range of measures in line with current U.K. government and NHS [National Health Service] guidelines to minimize the spread of the virus and ensure that productivity didn’t come at the expense of staff safety.

“Importantly, we have continued to successfully work with tobacco brands around the world and implemented a range of supply chain protocols, which have enabled us to operate at full capacity throughout the pandemic. We have excellent supply and stock management systems in place, and we are continuing to meet the increased demand from our customers across all markets.”

Recently, I had an ice cream bar from a stash in our freezer. I appreciate the own-brand product in question because the supermarket that offers it has gone to the trouble of catering for vegans such as me and is offering a tasty ice cream bar whose production is almost certainly more environmentally friendly than that of the usual animal-products-based ice cream bars. And while the vegan ice cream bars are wrapped in nonrecyclable plastic, the wrapping is thin, and the whole is offered in a recyclable cardboard box.

Recently, I had an ice cream bar from a stash in our freezer. I appreciate the own-brand product in question because the supermarket that offers it has gone to the trouble of catering for vegans such as me and is offering a tasty ice cream bar whose production is almost certainly more environmentally friendly than that of the usual animal-products-based ice cream bars. And while the vegan ice cream bars are wrapped in nonrecyclable plastic, the wrapping is thin, and the whole is offered in a recyclable cardboard box.