The public health and environmental health communities should unite to ban cigarette filters for the benefit of both people and planet, according to the authors of a study from the University of Bath that was published in Tobacco Control.

Introduced in the 1860s to prevent tobacco flakes from entering the smoker’s mouth, cigarette filters were later marketed as tool to reduce the health risks from smoking. Research shows that filters do not reduce those risks, however, and may even increase them by enabling smokers to inhale more deeply, according to the authors.

In addition, filters are an environmental hazard. Every year, an estimated 4.5 trillion cigarette filters are deposited into the environment. Discarded filters are commonly made of cellulose acetate—a plastic losing on average only 38 percent mass in two years of decomposition—and contain toxic substances that may leach into the environment.

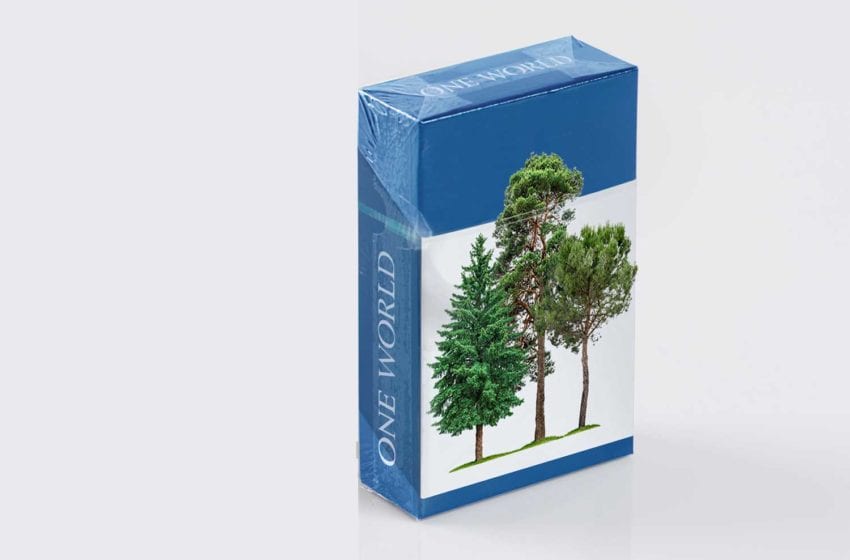

The study’s authors are skeptical about industry efforts to develop biodegradable filters, which they say would still leach harmful chemicals into the environment if discarded improperly.

What’s more, biodegradable filters could be used to promote smoking and improve the tobacco industry’s image. “It is likely that the tobacco industry will use biodegradable filters as both a corporate social responsibility and marketing opportunity,” the authors write.

It is likely that the tobacco industry will use biodegradable filters as both a corporate social responsibility and marketing opportunity.

Study “The Filter Fraud Persists”

The researchers also take issue with innovations such as recessed filters and “crush” filters, which they say are designed to make cigarettes more appealing and help tobacco companies circumvent advertising restrictions.

According to the study’s authors, the EU Single Use Plastics Directive missed a crucial opportunity by excluding cigarette filters from its upcoming ban on single-use plastics. “In the U.K., the tobacco industry’s new responsibility for smoking-related litter clean-up has already been used as an opportunity to have in-person interaction with the government, thereby exploiting this as a loophole in the WHO FCTC treaty,” they write.

This study was carried out by Karen Evans-Reeves, Kathrin Lauber and Rosemary Hiscock and supported by Bloomberg Philanthropies Stopping Tobacco Organizations and Products project funding.

Tobacco Reporter covered filter manufacturers’ efforts to meet new environmental requirements in its March issue (see “Keeping Pace“).