Ronald Woodthorpe passed away on March 26, 2024, at age 86 after a three-year fight with dementia. He is missed by his surviving family and friends, but his legacy remains at the heart of Hampshire Tobacco Machinery Services (HTMS).

Born in London in 1938, Woodthorpe was always a hard worker, training as a toolmaker after finishing secondary school. He took a job with Robert Legg in 1964 as a toolmaker—the company manufactured tobacco machinery and domestic appliances at the time. The next year, Robert Legg was acquired by American Machine Foundry Co. and renamed AMF-Legg, specializing in machinery for preliminary leaf processing and the processing and manufacture of cigarette and pipe tobacco. During this time, Woodthorpe developed a love for the industry that would span decades.

In 1974, Woodthorpe was approached by John Payne, a director from AMF-Legg, with the idea to start a new business reengineering and upgrading machines for the tobacco industry. Thus, John Payne Engineering was born, and Woodthorpe was named technical director. The company quickly grew, supporting larger manufacturers like Imperial and BAT. Woodthorpe was involved with developing an upgraded, faster hinge-lid packer based on the Molins HLP 2 during his time at the company, and he inspired a technology transfer with Bulgartabac in the 1970s.

John Payne Engineering was eventually sold in 1986 to Evered Holdings and later became part of GBE International. This didn’t sit well with Woodthorpe, who decided to start his own business: HTMS.

HTMS began as a supply company in 1987, supplying spare parts for Molins and Sasib/AMF machinery from a small office and store in Southampton. Woodthorpe’s contacts in the industry supported him, and the business developed well. In 1988, Woodthorpe’s daughter, Gillian, was hired to assist with business administration. Two engineers were then hired to facilitate workshop activity.

Three years later, the company moved to a larger office with stores beneath and a separate workshop facility. There, they began rebuilding Sasib/AMF soft packing machinery lines. Within the next five years, Woodthorpe’s daughter-in-law, Sara Fielder, and his youngest son, Peter, joined the company. By 1998, HTMS moved again to a larger space across the road, which is where it currently resides.

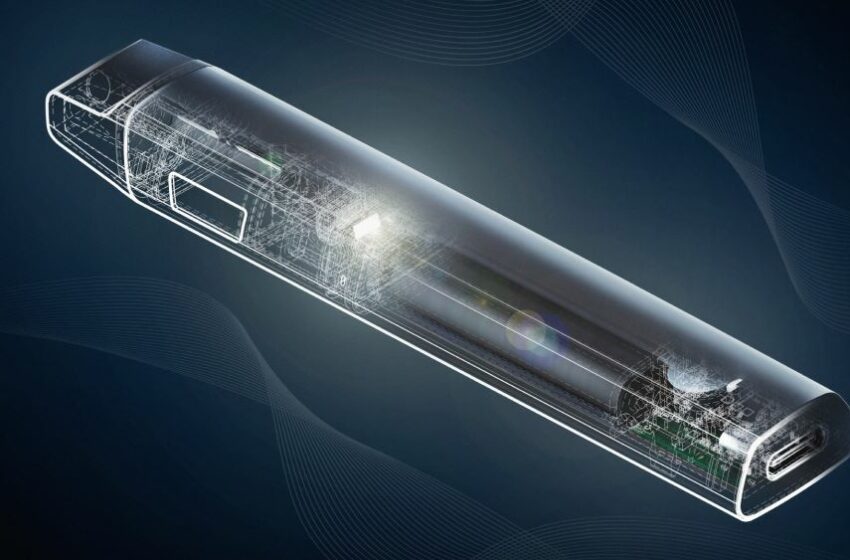

Over the next couple years, HTMS bought the rights, technical drawings and casting patterns for the high-speed XL Hinge Lid Packer from John Payne Engineering and GBE making and packing, and Robert Brown, a Molins packing expert who worked with Woodthorpe at John Payne Engineering, was hired. The hinge-lid packer became HTMS’ flagship machine, and Brown’s addition to the team allowed Woodthorpe to further develop the high-speed hinge-lid packer and its associated downstream machinery.

Woodthorpe was determined, a hard worker, a hard taskmaster and a man who generally would not take no for an answer. The tough standards he placed on himself were reflected in his work ethic and care—he tried every day to do the best he could for his business and his family. Those who knew him felt he was a very fair man who would always get you where you wanted to be and would support you in a time of need.

“Ron always saw the best in people and encouraged those to find it in themselves,” said Brown. “In that way, he inspired others to achieve levels that they never thought possible, and I was certainly one of those. As long as you tried your best, you were never a failure in Ron’s eyes.”

HTMS continues Woodthorpe’s ethos of service—the ability to supply immediately and support in times of need. HTMS understands that off-the-shelf supply is paramount to the business and its customers, thanks to Woodthorpe’s dedication and care over the years. Today, the company’s main focus is cigarette and cigar packaging, but it still provides primary equipment in the form of tobacco-cutting machinery and cigarette/cigar making machinery and spares.

“People talk about a work-life balance—well, Ron was one of the only people I’ve ever known who loved to ‘live to work’ as much as he did ‘work to live,’ simply because he had an equal amount of love and passion for work as he did his family,” said Sara. “Ron worked longer and harder than most because he wanted to make sure his family were taken care of but also because he loved the job and everything that it encompassed.

“Ron’s dedication to taking care of ‘all of us’ over the years gave us, the HTMS team, the drive to continue in succeeding where he left off after his retirement, even more so now to continue further to honor his memory,” she said.

Dedication is a clear theme of Woodthorpe’s life. He retired in 2020 at age 83 after a full life and career, leaving his company under the care of Peter, Sara and Jeff Perress. Even when he retired, it was less from a desire to retire and more from Covid-19 pandemic concerns, according to his son.

In 2021, Woodthorpe was diagnosed with vascular dementia. Despite the struggles that caring for a loved one with dementia brings, Peter remembers his dad’s lessons of “Never put off till tomorrow what you can achieve today” and “If it’s not fun, don’t do it.”

HTMS carries Woodthorpe’s core beliefs in quality, value and service at the heart of the business. And though he will be missed, his legacy will live on. “Ron’s enthusiasm, dedication and enjoyment for the job was passed on to all who worked for him,” said Howard Rich, a former colleague.