Originally developed to reduce cost, reconstituted tobacco helps tobacco companies custom-design their blends, including for novel nicotine products.

By George Gay

As is my custom, I would like to start off by writing about something of which I know very little: in this case tea. Although I’m English, I’ve never drunk tea, but I have spent years surrounded by people who are steeped in it, and I have noticed that whereas some years ago the people of my acquaintance who drank tea mostly brewed it from leaves, now they mainly use teabags. At first, people tended to look down their noses at teabags because they didn’t contain ‘real tea’, and I often heard people say that teabags contained only tea-dust swept up from the factory floor. I have no idea whether or not this was true, but it is obvious that people came to see the advantages offered by such a product, not least its convenience. It was a product that had been engineered for its time; or perhaps it was a piece of product engineering that allowed cultural shifts that people were ready to embrace.

As is my custom, I would like to start off by writing about something of which I know very little: in this case tea. Although I’m English, I’ve never drunk tea, but I have spent years surrounded by people who are steeped in it, and I have noticed that whereas some years ago the people of my acquaintance who drank tea mostly brewed it from leaves, now they mainly use teabags. At first, people tended to look down their noses at teabags because they didn’t contain ‘real tea’, and I often heard people say that teabags contained only tea-dust swept up from the factory floor. I have no idea whether or not this was true, but it is obvious that people came to see the advantages offered by such a product, not least its convenience. It was a product that had been engineered for its time; or perhaps it was a piece of product engineering that allowed cultural shifts that people were ready to embrace.

Tea can be compared with tobacco in this regard. Once upon a time, tobacco waste was waste; but 40 or so years ago it was found that this “waste” could be swept up and made into reconstituted tobacco, which could be included as a proportion of a tobacco blend. As with tea, at first, reconstituted tobacco was seen very much as the poor relation of the blend, but manufacturers came to realize that this tobacco offered advantages, especially in regard to blend stabilization and, of course, costs.

Across the world, the products that we use are becoming more engineered, and, wherever possible, waste is being eliminated, if not for its own sake, at least in the name of cost savings. Reconstituted tobacco virtually eliminates tobacco waste, and its engineering is becoming ever-more sophisticated—even to the point where the possibility of customized tobacco, and therefore customized tobacco products, is a reality. Reconstituted tobacco might not be the future, as some might imagine it to be, but it has to be a significant player in the future.

Designer tobacco

Most people working within the tobacco industry are probably aware of this direction of travel, but what some probably don’t appreciate is just how far this tobacco engineering can go in helping manufacturers develop their products.

Perhaps the ultimate engineering of a tobacco product to date is to be seen in heat-not-burn vapor devices, which, by including tobacco, have been engineered so as to nudge up close to traditional combustible cigarettes in relation to their taste profiles, but, in not burning that tobacco, have been designed so as to open up a gap in relation to the level of risk that they pose to the consumer.

Reconstituted tobacco, I am told, is a necessary component of heat-not-burn products, because the tobacco they contain has to be closely designed. This, apparently, is not possible to achieve with leaf tobacco even if a manufacturer were willing to use genetically modified leaf, but reconstituted tobacco can deliver, for instance, a single American-blend sheet that includes specified levels of flue-cured, Burley and oriental tobaccos, and that delivers a specified level of nicotine.

Looking at this issue from another direction, Iqbal Lambat, the CEO of Star Tobacco International, said it was clear that the use of reconstituted tobacco in novel nicotine products (NNPs), such as heat-not-burn devices, was logical because it was significantly cheaper than most cheap tobaccos on offer.

But he wasn’t getting over-excited about this development. Reconstituted tobacco’s growth in this category, he said, would be directly proportional to the success of the category, and since most market studies at this stage pointed to a market share for NNPs of 3-5 percent of global consumption by 2030 at the earliest, it was not currently seen as a game changer for reconstituted-tobacco utilization growth.

Asked about the current and future utilization of reconstituted tobacco in all tobacco products, Lambat estimated that demand was currently at the level of about 350,000 tons a year, a figure that he believed would continue to rise given that increasing legislation would favor the development of more low-tar and nicotine products.

Other uses

Some people are slightly less optimistic in this regard. They point to the fact that the worldwide cigarette market is slowly declining and that while it might be the case that reconstituted tobacco will take a larger share of the filler component of cigarettes in the future, that increase will offset rather than compensate for the decline in cigarette sales.

Most reconstituted tobacco is used as a filler in cigarettes, but this is by no means the only use. It is used also as a cigar filler, binder, wrapper and tipping paper. And generally speaking, the demand for reconstituted cigar tobacco is more stable than that for cigarette filler, though that demand has taken a severe hit in recent times and is about to suffer another. The first hit came with the advent of the EU’s revised Tobacco Products Directive, which brought in a minimum weight for cigars that basically wiped out overnight the reconstituted tobacco wrapper business in Europe. From that point, all of the small, reconstituted-tobacco cigars became liable to be taxed as cigarettes, something that took away their main selling point—price.

The second hit to the cigar business is being delivered through the U.S. Food and Drug Administration’s so-called deeming regulations that require cigar manufacturers to undertake a burdensome and expensive approval process in respect of new products, and that are likely to put a brake on product development.

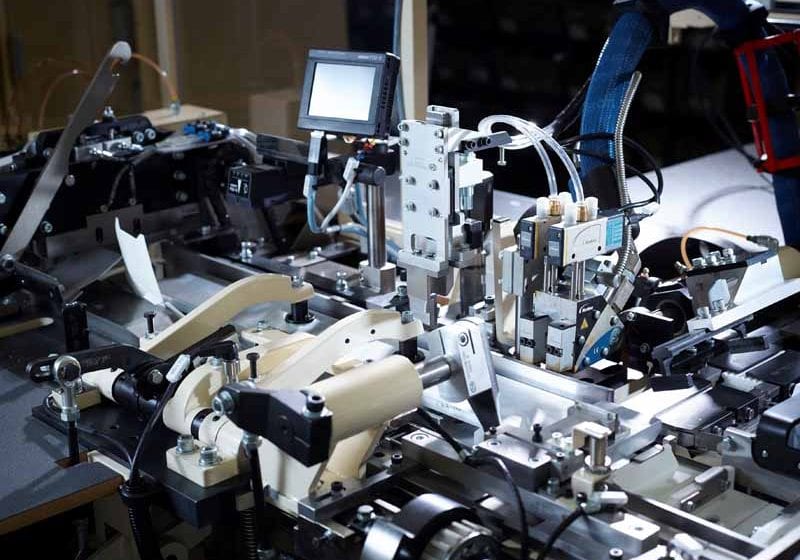

But none of this means that the reconstituted tobacco cigar business is slowing down. Far from it. In recent years the speed of manufacture of cigars has reached the low end of cigarette manufacturing speeds, and the reconstituted tobacco used in these processes has had to be developed to meet the challenges of these new manufacturing capacities. With the increased speeds, the mechanical strength of the reconstituted tobacco used for manufacturing cigars has had to be increased so that it can be used on machines capable of making up to 4,000 pieces a minute.

Something for everybody

But perhaps the real opportunities will arise because of the move to more-customized tobacco products and the ability of reconstituted tobacco to deliver such customization. The demand for increasingly customized products is one that cuts across most types of products, from cars to computers and from bicycles to sandwiches, and so whereas previously a reconstituted-tobacco company might have had one product that fitted all demands, now it has to have many different products to meet the specific needs of individual customers. Customers now want reconstituted products in different sizes with different mechanical properties. Some want these sheets to glue more quickly than run-of-the-mill products, and some want them to be water resistant. And customers now look for different flavors and different colors. In all, there are something like 100 different characteristics that can be specified.

Interestingly, this offer of customization arises at a time when the exact opposite seems to be happening, when brands are being merged; so perhaps the smoker of the future will have more choice than smokers do now. Regulations allowing, manufacturers will have the opportunity of offering cigarettes with specific characteristics to do with deliveries, tastes and smoke profiles.

And even more interesting, perhaps, is the fact that it is possible to incorporate all of the tobaccos needed for a blend into one reconstituted sheet; so, in theory, eventually all tobacco companies could get rid of their blending departments. In fact, the thing that is holding up such a development is perhaps not to do with reconstituted-tobacco technology, but with the fact that tobacco companies are currently focused on meeting other challenges, such as those concerning legislative changes.

Manufacturing technologies

There are a number of different methods for producing reconstituted tobacco from, for instance, stems, scraps, dust and fines, individually or in combination. But as Lambat said, the most common reconstituted tobacco is made using the paper process, which originated in the 1970s with Kimberly Clark USA technology. At that time, reconstituted tobacco was purely a cost-saving technology for using up fines and tobacco waste, he said. But over time, reconstituted tobacco had become a core ingredient in blends and been manufactured as a distinctive type or grade.

Various technologies had been developed during the past 10 to 15 years, notably “slurry technology,” which used a vegetable binder, and “nano fiber technology,” which was a much-improved form of the paper process, delivering reconstituted tobacco with high filling power, high aroma, good burning qualities and taste enhancement. Star offered from Brazil reconstituted tobacco produced using the nano fiber technique, and reconstituted tobacco from China made using the paper-making technique.

Whatever the technique, reconstituted tobacco can offer much. It is a stable product that suffers less from crop variation than does leaf, which is an advantage when the aim is to produce a product with the same taste year after year. It offers manufacturers financial advantages, and control advantages, such as in respect of nicotine and tar levels. It offers advantages when it comes to designing new products or modifying existing ones.

But the main application for reconstituted tobacco, Lambat said, was to develop tobacco blends with reduced tar and nicotine deliveries, and to help smooth and round-up the smoke taste in combustion products such as cigarettes and cigars. And because reconstituted tobacco had a higher filling power than did leaf tobacco, cigarettes made from blends with reconstituted tobacco required up to 10 percent lower tobacco usage. This, he said, went center stage towards cost reduction.

The cost/price argument is compelling. Lambat said that some customers were willing to pay $8-10 for top Zimbabwe flue-cured tobacco grades; so the question arose as to what they would be willing to pay for Zimbabwe reconstituted tobacco that had a similar color line but slightly reduced chemistry. The same question arose in the case of, say, Malawi Burley and Turkey’s Izmir oriental. Izmir leaf, he said, sold for in excess of $10 per kg, but the cost of Izmir scraps and stems would allow reconstituted Izmir to be offered for $4 per kg, which would represent a substantial discount for the buyer while still generating a healthy margin for the reconstituted tobacco manufacturer.

Star, in fact, offers reconstituted oriental tobacco. And it has developed a reconstituted kretek tobacco, which, Lambat said, was being tested by some of the leading Indonesian cigarette manufacturers, “with initial reviews pointing to a successful breakthrough.”

Still with customized products, IOTO International offers reconstituted tobacco out of its Brazil and U.S. (IOTO USA) plants using its patented TREX process to produce a range of reconstituted products, including US blends and single varieties, such as Burley and oriental.

Marcel Astolphe, the general manager of IOTO International, said the TREX process could use all kinds of tobacco by-products, supplied by its customers or sourced by IOTO, to generate reconstituted tobacco as bobbins, square pieces, shredded sheet or cut-filler.

The company has sold machinery and licensed the TREX process to clients in the U.S. and Russia. It is involved also in a joint venture with Alliance one in Purilum, which is specialized in the development of e-liquids and e-liquid flavors.