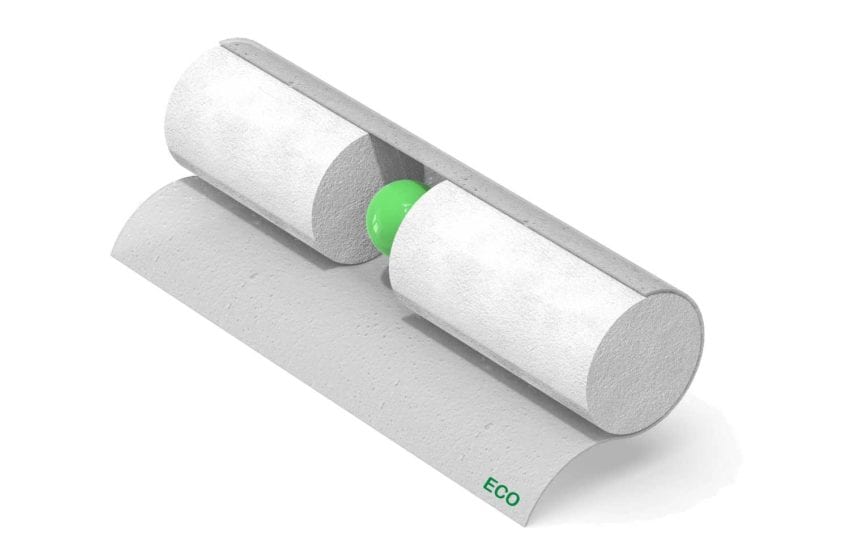

Essentra Filters has launched three new proprietary products—ECO Cavitec, ECO Sensation, and ECO Cavitec Sensation, delivering a plastic-free, 100 percent biodegradable alternative while maintaining the unique sensorial attributes, performance and quality characteristic of Essentra Filters.

“Although recent trends have brought the topics of single-use plastics and sustainability to the forefront of the conversations, Essentra Filters has always been committed towards a sustainable future,” says Seng Keong Low, global marketing manager at Essentra Filters.

“We have continuously been innovating new, high quality, eco-friendly products, with existing offerings such as our paper-cellulose acetate mix Bitech Filter to single-segment paper filters such as Myria and Ochre Filters. In the latest step of our sustainability evolution, our new ECO Cavitec, ECO Sensation and ECO Cavitec Sensation filters offer a plastic-free, 100 percent biodegradable alternative with unique sensorial attributes and quality performance, a true revolution in filters technology.”

The ECO Cavitec Filter is a proprietary, patent-filed, eco-friendly filter with unique sensorial attributes, reducing the efficiency of a typical paper filter to allow for a fuller flavor delivery. Manufactured using Essentra’s market Cavitec technology, the design is customizable and can be combined with any other segments, in addition to customization for the size, cavity length, number of cavities, pressure drop and constructed material, i.e. paper or other nonwoven materials.

The ECO Sensation Filter is a proprietary, eco-friendly filter option to engage the consumer with his or her senses. A capsule is embedded in the paper material during manufacturing and can be crushed at any point, giving consumers control of their taste experience. In addition to customization of capsule type, cavity size, or use of colored plugwraps, ECO Sensation Filter can be manufactured using different paper types, combined with other end segments, or make use of Essentra’s Infused technology to achieve additional sensory benefits.

A proprietary patent filed filter, ECO Cavitec Sensation is an eco-friendly filter with three unique sensorial attributes, combining the properties of non-woven materials with the Essentra’s Cavitec technology. As the capsule is free to move within the cavity, consumers can hear the capsule rattle within the cavity while feeling the vibration through the fingers.

The capsule can be crushed at any time, providing consumers flavor on demand. As with all offerings from Essentra Filters, the design of ECO Cavitec Sensation is customizable and can be manufactured using different paper types, combined with other end segments, or make use of Essentra’s Infused technology, in addition to customisation of capsule type, cavity size, or use of colored plugwraps.

Cerulean has launched a new stand-alone Aerosol Temperature Measurement System (ATMS), the company announced on its

Cerulean has launched a new stand-alone Aerosol Temperature Measurement System (ATMS), the company announced on its