The U.S. International Trade Commission (ITC) has opened a probe into vapor products imported by cigarette giant Philip Morris USA (PM) after R.J. Reynolds complained that PM’s tobacco-heating system infringes Reynolds’ patents, according to a report by Law360.

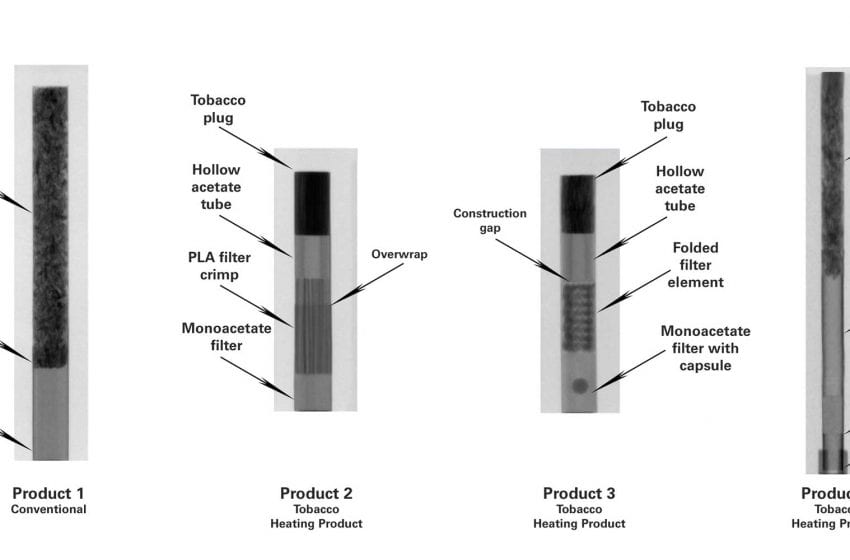

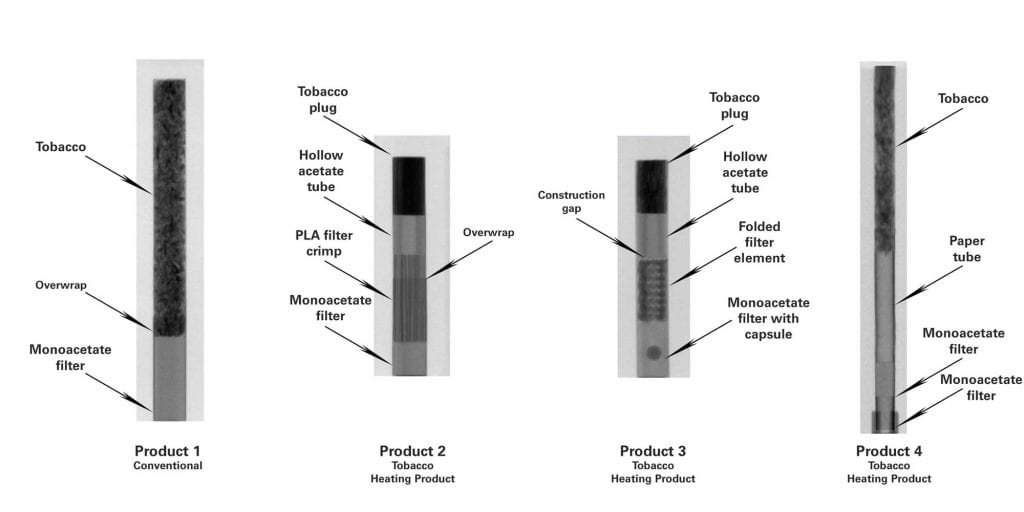

The investigation will determine whether the IQOS tobacco vaporizers marketed by Philip Morris and parent company Altria use tobacco-heating systems and sticks that violate patents for R.J. Reynolds’ Vuse vaping system. R.J. Reynolds seeks cease-and-desist orders barring imports of the allegedly infringing products.

The patents describe a device that heats tobacco held in a removable cartridge to 350 degrees when vapors containing nicotine are released without producing smoke, according to R.J. Reynolds’ April 9 complaint to the ITC.

R.J. Reynolds, which is owned by British American Tobacco, said Philip Morris has sold the alleged copycat IQOS system in the U.S. since October 2019 and has imported the product from manufacturers in Italy, Switzerland and Malaysia for years to use in clinical testing.

“We believe the allegations are without merit, and we are fully prepared to defend ourselves,” Philip Morris spokesman Corey Henry told Law360 in a statement Wednesday, noting the company has spent $7 billion developing its smoke-free tobacco products over the past two decades.

R.J. Reynolds filed a suit accusing Altria and Phillip Morris of six counts of trademark infringement in Virginia federal court the same day R.J. Reynolds filed its ITC petition. In that case, the company seeks treble damages and court declarations that Altria and Philip Morris have infringed its intellectual property.