Cerulean has expanded its range of next-generation nicotine product testing equipment.

By Stefanie Rossel

As the nicotine industry and its regulators continue to focus on novel nicotine products, it is no surprise that reduced-risk product testing receives a lot of attention in instrumentation suppliers’ R&D departments.

“We are still in many ways ignorant of the impact of the aerosol from vapes and heated-tobacco products (HTPs) on respiratory systems, especially when the aerosols are laced with flavors that are safe for ingestion but not necessarily so when dosed to the lung,” explains Ian Tindall, head of innovation and marketing at Cerulean, a U.K.-based supplier of precision test and measurement equipment that belongs to the Coesia group. “This sort of work is needed for regulatory submissions for sure. It is also prudent to be certain that changes in formulation have no unforeseen consequences.”

Cerulean has been developing testing equipment for HTPs and e-cigarettes, cannabis vaping and modern oral nicotine recently. For HTPs, Cerulean has a comprehensive suite of products that is either already available or will be released this year. Tindall says Cerulean has launched a couple of new machines specifically for toxicological testing of HTPs this year. “One is a budget model—the CETI5 that produces a constant aerosol from HTPs and includes pre-activation options for HTPs plus puff control, angled use, button pressing and so on,” he says. “Unusually it uses a five-puff engine configuration, which removes the necessity for moving valves and items under test. We think of this as an entry model to the world of aerosol generation for toxicology studies.”

“CETI” stands for Cerulean E-Cigarette Testing Instrument and is the name of a whole range of products that can be used not only to test HTPs but also to assess e-cigarettes and cannabis vape products. The CETI5’s continuous exhaust is created by synchronizing the puff engines to sequentially exhaust and generate a constant flow of aerosol—a feature highly desirable for toxicological exposure studies. Users can program a puffing routine to establish deliveries from various e-cigarette, cannabis vape and HTP devices. The angled vaping option is meant to mimic human use. In line with recommended regimes for HTPs and vape products, the CETI5’s regimes can be configured for different puff volumes, puff duration and puff interval.

HTP Assessment

The CETI CF, meanwhile, features a more conventional rotary-type setup with a moving valve. According to Tindall, it is considerably more sophisticated in terms of the analytical options available, including impingers and electrostatic precipitator traps as well as air-liquid interface exposure systems. “The software is more flexible with a full traceability package, which is quite important for regulatory submissions.”

The CETI CF is a continuous-flow, five-channel vaping machine that complies with ISO20768:2018. It is designed to run as a continuous aerosol generation device through the use of the dual piston pump situated at the heart of the machine. The pump, which can pull puff volumes of 35 mL to 150 mL, switches between inlet and outlet, creating a continuous aerosol that can be delivered to any target system required. The glass construction of the dual pump and its ease of removal allows for thorough cleaning, thereby minimizing cross-contamination between runs. The CETI CF comes with a fully capable interface that is simple to use, includes security features and can be interfaced with a laboratory information management system.

In addition to developing new machinery, Cerulean has added to its X-ray measurement a capability that looks inside sticks and measures hidden parameters by offering the facility that the company has on its Quantum Neo test station for 150 mm-long rods X-rayed as part of a suite of measurements. “We have separated this [function] out and come up with a stand-alone X-ray system in the Solo Q device,” says Tindall. “It has all the safety features you would expect as well as a user interface tablet that can be removed from the stack for easier handling.”

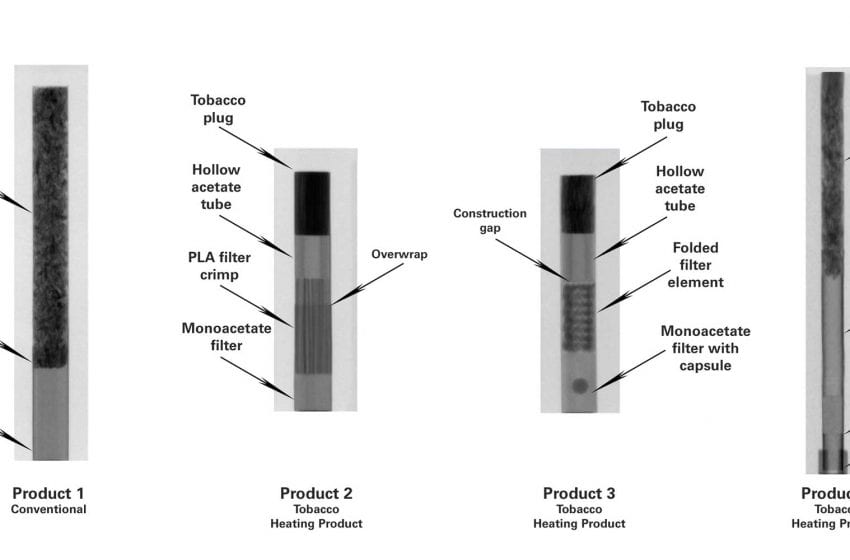

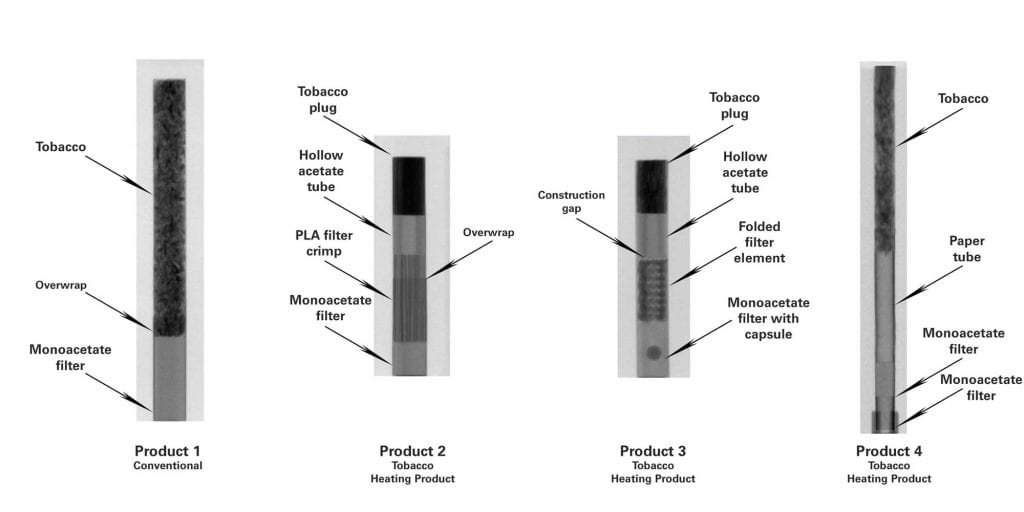

Instrumentation for assessing HTPs is presently most sought after by customers, according to Tindall. “HTPs are simply the big kid on the block,” he says. “The designs are settling down—although if you look at the array of patents being published, you may argue differently. Key quality measurements seem to be those measured after the combiner has done its job. Standard equipment can mostly ensure component manufacture is correct. Hollow acetate tubes have required some different inspection that we introduced last year, but essentially, this is all pretty standard stuff. The combiner is where everything comes together, and here, any defect in construction will impact the consumer experience, so this is where innovation in test equipment is focused. The X-ray system is one example of finding a solution to investigating potential construction faults. Another is the addition of a closed-loop control to the combiner or maker.”

A Rising Star

The up-and-coming field in quality assurance (QA) is modern oral. “The principles look simple, but QA testing is still a bit hit-and-miss,” says Tindall. “As these pouches become more sophisticated with different contents, capsules, formats and colors, this is going to be an expanding market.”

In early 2022, Cerulean launched Orion, the first automated test station for snus, which measures the weight, length and width and the tensile strength of the pouch seams as well as extension against load. “To date, we are very pleased with the impact Orion is making in the marketplace, and we have struggled to get enough machines directly in front of customers,” says Tindall. “One of the bizarre things for us has been [that] when we talk about testing pouched products, we get mixed responses. When we show the equipment, almost universally the interest transforms, and we end up adding a new name to the list of people wanting to trial the equipment.”

Cerulean has further developed Orion by adding a moisture measurement station. “This was specifically designed for pouches with more than 15 percent moisture, as many of the white snus pouches have,” says Tindall. “It is quick and is part of the automation and so complements standalone systems that may be slower or more suitable for dry pouches. We have some further ideas for quality parameter checking and are developing the fundamental technologies, but these will not reach maturity for 18 months.”

Cannabis is Cerulean’s third priority, according to Tindall, but a lack of legislative drivers and a volatile market make it difficult to effectively serve a potential customer base. “We published a suite of white papers, available on our website, with our Denver-based partner Kaycha Laboratory, which were all concerned with THC aerosol generation specifically for capture and subsequent metals analysis, as specified by the Colorado state regulators,” he says. “We showed, with Kaycha, that we needed specific conditions to get high THC content liquids into the aerosol phase, and we developed a specialist heater jacket that we made available in our catalogue that keeps the THC oil liquid warm, allowing a low viscosity for analytical experiments. We then worked with Kaycha on a capture system because electrostatic trapping simply does not work. In the end, we sourced low metal content quartz capture pads for Kaycha, and they can now effectively report the limited selection of metals in aerosol that Colorado requires.”

The company also made improvements to its THP and cannabis testing products. “We have added the heater jacket for cannabis products, which fits on any of our smoking and vaping machines,” says Tindall. “And we have launched the CETI1, a simple single-channel vaping machine for research projects. It retains all the features of more sophisticated machines without the typical high cost.”

Among the innovations was also an enclosure for the CETI8, an eight-channel vaping instrument, to capture any fugitive emissions. The hood covers only the operational portion of the machine, comes with several filters and allows for a complete air exchange within two minutes. According to Cerulean, the enclosure is effective at stopping unwanted odors from reaching users. Furthermore, it mitigates the ingress of contaminants to laboratory surfaces. “It came about after our portfolio manager, Helen Taylor, and I were working in a cannabis lab and realized that at the end of the day, our heads were singing from low-level exposure to cannabis aerosol,” says Tindall with a smile.

Cerulean has two big releases planned for the fourth quarter of this year, but Tindall is quick to stress the company’s continued support for exiting equipment. “It’s always fun to talk of new products and market opportunities, but we must not forget that there is a hell of a lot of equipment still in use from years past, and we make a point of supporting the needs of those customers as well,” he says. “That is why, on top of our service team and technical support team, we are actively ensuring that equipment can be modernized through upgrades so that a machine maybe bought 10 years ago can be updated to a current specification with all that implies for the changing face of our industry.”