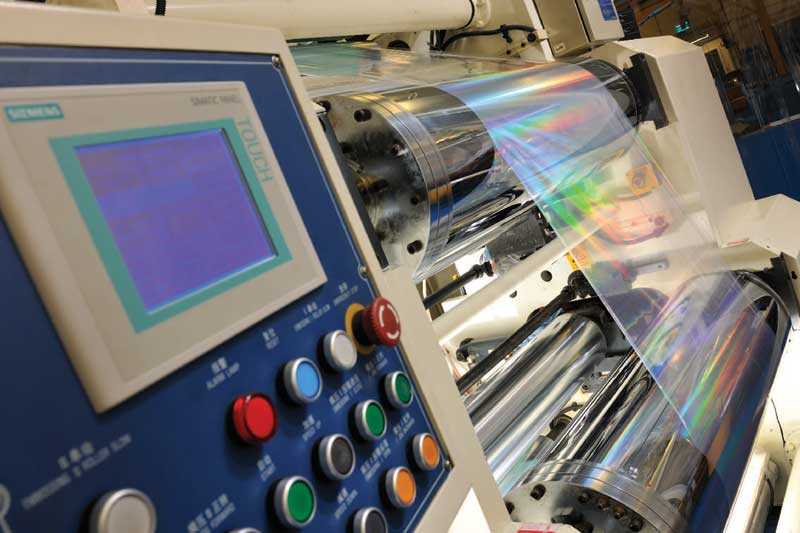

Goebel IMS installed two Monoslit 9000 slitter rewinders on Guangdong Decro’s high-speed BOPP film production lines.

Guangdong Decro Film New Materials Co. is one of the top manufacturers of BOPP film in China, featuring four subsidiaries—including Guangdong Decro Package Films Co.—and three manufacturing facilities that total more than 187,000 square meters. Currently, Decro runs seven international advanced BOPP lines, two functional coating lines and ten twin-screw extruders for functional Masterbatch.

The two Goebel machines have a 1,200 meters per minute speed and the newest design and technologies for processing special kinds of BOPP film.

“As one of the worldwide leading BOPP manufacturers for specialty films, we always require sophisticated high-end equipment to meet our customers’ demand,” said He Wenjun, vice president of Guangdong Decro Package Films Co.

“We are happy to have identified Goebel IMS as a trustworthy partner for our primary slitting and rewinding operations. The performance of the machines exceeds our expectations and especially the second line was installed and operating in record time. We are looking forward to continuing our positive working relationship with Goebel IMS.”

“We would like to thank Guangdong Decro for their trust in Goebel IMS and the good cooperation which enabled the very successful commissioning of the two primary slitters for their two new BOPP lines with a working width of 8.7 meters,” said Tobias Lanksweirt, managing director of Goebel Schneid- und Wickelsysteme.