(Photos: Montrade)

Montrade is expanding its portfolio and manufacturing facilities.

By Stefanie Rossel

There are clear signs that Montrade is continuing its remarkable growth: In the corner of the tobacco equipment manufacturer’s bright conference room, there are samples of tiles, wall coverings and other construction materials. The Bologna-based company is about to build new premises. About 200 meters from its current 4,000-square-meter site, it will construct an additional 7,000-square-meter shop floor, which is supposed to be finalized by the beginning of next year.

There are clear signs that Montrade is continuing its remarkable growth: In the corner of the tobacco equipment manufacturer’s bright conference room, there are samples of tiles, wall coverings and other construction materials. The Bologna-based company is about to build new premises. About 200 meters from its current 4,000-square-meter site, it will construct an additional 7,000-square-meter shop floor, which is supposed to be finalized by the beginning of next year.

“It will become our main company building with offices,” explains Alberto Monzoni, Montrade’s managing director. Together with his wife, Antonella Giannini, who serves as the company’s sales director, he founded Montrade in 2004. “The assembly workshop in the new building will have a bigger dimension because we’re growing also in terms of our portfolio as we are adding new machine models, and it will be fully dedicated to the assembly of our machines,” says Monzoni.

The current site, built in 2010 when the company had outgrown its original rented offices, will in the future accommodate a warehouse and tooling capacity. It already hosts the company’s spare parts manufacturing center, which is equipped with a CNC machine and will become a preferred sub-supplier for Montrade machinery after the expansion. The building is also home to a startup company, with a team dedicated to the development of special sensors, mainly for the inline quality control of filters that Montrade installs in its machines or sells as part of retrofit kits for its equipment. “The team will get more space with the option to increase capability. Inline control is important as high speed requires high quality.”

Monzoni says it’s essential that Montrade, which exclusively supplies the tobacco industry, enlarges its footprint. “Multinational companies have become an essential part of our customer base, and they require a certain capacity.”

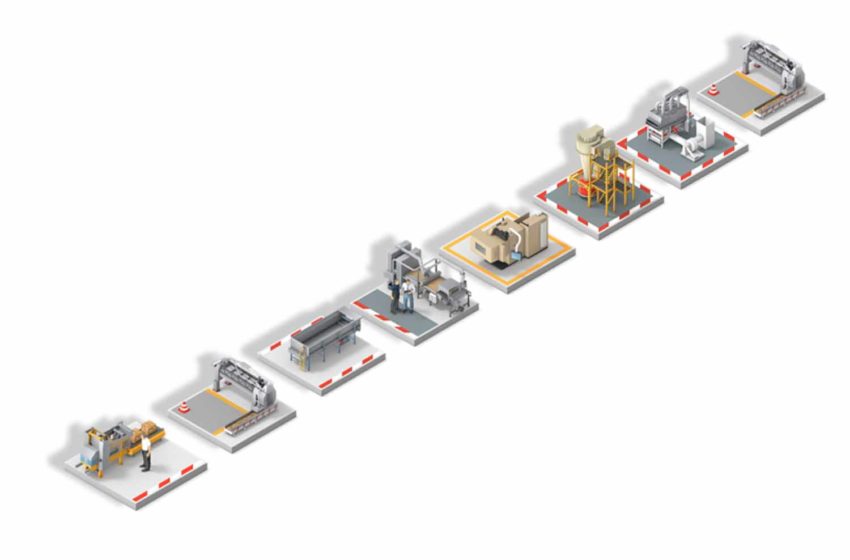

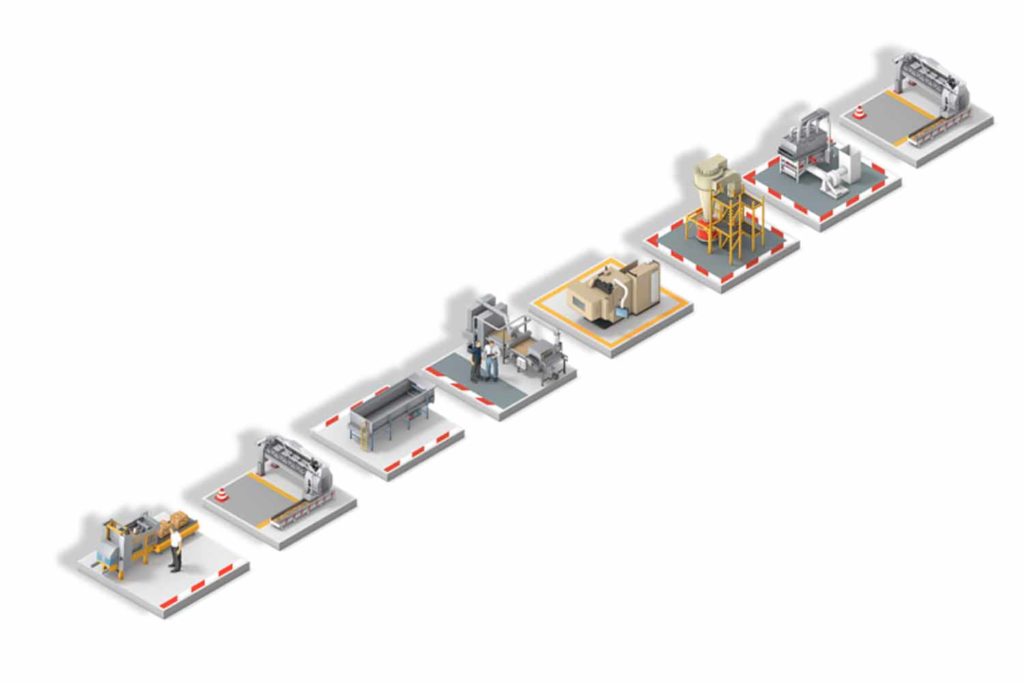

With 120 employees, the company presently manufactures about 30 lines per year. Montrade offers a wide range of equipment ranging from filter-making to packaging for combustible cigarettes and heated-tobacco products (HTPs). “It’s vital for us to meet the new market requirement of flexibility,” says Giannini. “Due to the increasing amount of products, the complexity of the tobacco industry is intensifying. Montrade covers everything from roll-your-own [RYO]/make-your-own [MYO] to packing lines, always with a view to sustainability.”

Environmentally friendly filter solutions, Giannini and Monzoni believe, will be the next big thing in the industry. Discarded cigarette filters, 98 percent of which presently consist of cellulose acetate (CA), a bio-based polymer that takes years to disintegrate, are the world’s most littered items. They pollute the environment with microplastics. In July 2021, the European Union banned plastic items such as plates, cutlery, straws or cotton bud sticks but exempted cigarette filters. Instead, tobacco manufacturers will be required to cover the costs of consumer awareness-raising campaigns and extended producer responsibility schemes starting in December. There are rumors, though, that the EU might ban CA filters in the future. Giannini considers it more likely that the EU will raise taxes on polluting items instead. The tobacco industry is taking the issue seriously by developing paper filters, a trend that Montrade has seen reflected in the demand for corresponding machinery.

Efficient Paper Crimping

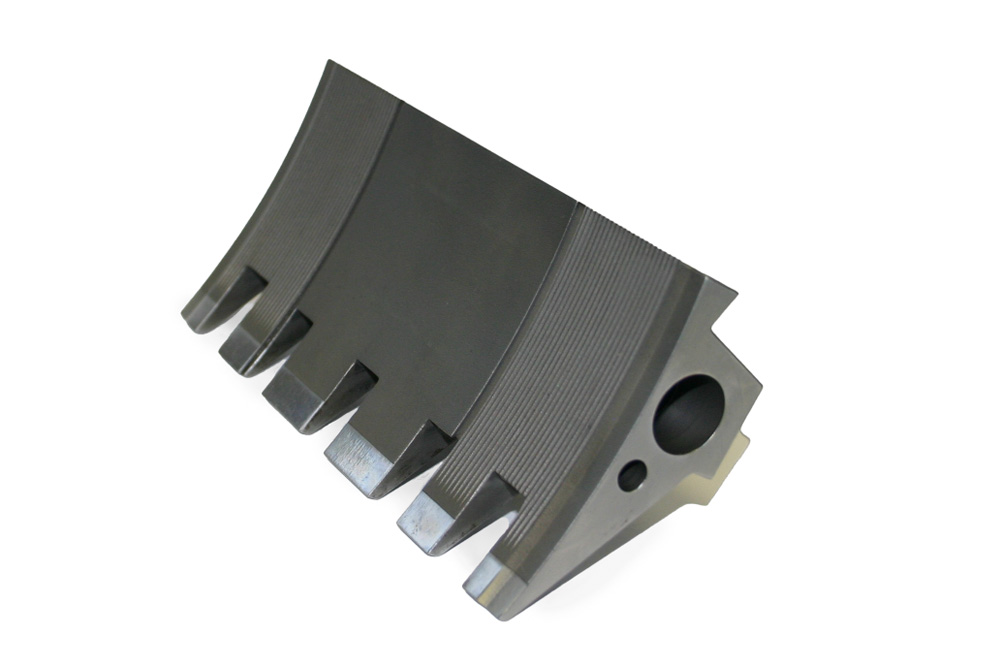

One of Montrade’s bestsellers is a new version of a paper crimper that was originally developed in 2010. Paper is crimped with a pair of rollers that penetrate the paper band without cutting the fibers. The goal of the process is to get the maximum volume so that when the rod is made, the filter doesn’t have any holes; it should look as much as possible like a filter made from CA.

One of Montrade’s bestsellers is a new version of a paper crimper that was originally developed in 2010. Paper is crimped with a pair of rollers that penetrate the paper band without cutting the fibers. The goal of the process is to get the maximum volume so that when the rod is made, the filter doesn’t have any holes; it should look as much as possible like a filter made from CA.

Driven by customer requests, Montrade recently redesigned the crimping head of its machine to enable the manufacture of paper filters with similar properties to CA filters. “With our new technology, we have achieved excellent results,” Monzoni says. “We save 15 [percent] to 20 percent of paper compared to traditional crimpers, which means that we create a very homogeneous and stable filter with no variation in pressure drop and superb quality. Not only does this reduce cost; there is also an advantage for taste. The retention of paper is much higher than that of CA, which means that tar and nicotine will be reduced. If you use less paper, you will get less of the typical taste of a paper filter. For better machinability in the downstream process, we have increased the hardness.”

Importantly, Montrade’s machine works at the same speed as filter makers for acetate tow, splicing automatically and never reducing the speed of production, according to Giannini.

As an alternative to the paper crimper, the company offers the standalone crimping module as a retrofit package. Within 15 minutes, it turns a conventional CA filter maker into a paper filter maker. “If CA filters get banned, it doesn’t make sense economically to waste so many machines and replace them with new ones as the rod forming basically does the same job no matter whether there’s CA tow or crimped paper at the backend,” says Giannini. “The crimping module breathes new life into the existing rod forming, just giving it a new material feeding. We are getting a lot of positive response from our customers; you can see that this is the direction they will go. Many brands are making trials and have set up smoking panels with this new material.”

While demand for paper filter makers is increasing, Monzoni emphasizes that the trend is still at an early stage. “Paper filters are currently used for brand variants that appeal to consumers with a more ecological orientation,” he says. “The big brands are not ready yet. One [company] is prepared to start with one brand; others are still studying the subject.”

The situation is different in the smaller RYO/MYO category, which has become a forerunner in paper filter tips. “Sustainable filters are common, and the consumer likes them,” says Giannini. “In cigarettes, we’re still a bit behind. But the few brands with sustainable filters presently available are growing.”

Sustainable Solutions

Montrade’s portfolio reflects the tobacco industry’s current transformation that not only involves reduced-risk products but also non-nicotine offerings. For the rapidly growing cannabis market, Montrade is developing several products, including a cone-making machine.

Montrade’s portfolio reflects the tobacco industry’s current transformation that not only involves reduced-risk products but also non-nicotine offerings. For the rapidly growing cannabis market, Montrade is developing several products, including a cone-making machine.

The company is also exploring the potential of paper beyond common solid filter plug production. In partnership with a big tobacco firm, the machinery manufacturer has created a new packaging line capable of producing soft packs without plastic film. The humidity in the pack is preserved through an innovative seaming technology that reduced both cost and environmental impact.

Furthermore, the company uses the crimped paper to manufacture a hollow tube that is equivalent to hollow acetate filters. “Turning crimped paper into a hollow tube filter has long been the dream of filter designers,” notes Giannini. “Our customer wanted to change from CA filters to paper to have a full sustainable portfolio of paper filters. We have made it possible by offering paper tubes and hard paper filters. Our hollow paper tubes have a wall thickness of 0.6 mm to 1.5 mm, and they are very similar to CA filter tubes.” Montrade also has a machine that allows it to produce charcoal paper filters, which are also known as Dalmatians.

Used in combustible cigarettes, hollow filters make elegant mouthpieces. In HTPs, they are highly functional, serving as either a flow restrictor or an expansion chamber and playing a fundamental role in aerosol cooling and accelerating. “The performance of HTPs is driven by tubes,” Giannini says.

Drawing from its experience with crimped paper filter rod manufacture, Montrade has developed a rod-forming machine for the tobacco element in HTP consumables. The cast leaf that is used in the sticks presents a challenge in processing, says Monzoni. “It’s fragile and tends to be sticky, so it needs to be treated in a special way,” he says. The underlying concept of our rod maker, however, works for all bobbins or webs—you just need to adapt the technology to treat different materials.”

More design possibilities for HTPs arise with Montrade’s coaxial flexible platform, which represents a new way of making filters. “Instead of a single process, our machine has two garnitures and is capable of making one filter or tube inside of the other,” says Giannini. “It’s highly performing and super flexible, allowing for a continuous process or a combination of individual filter segments inside and a wrapping with a continuous material, such as paper or CA, outside, in one go.”

Customers’ biggest investments these days are in HTPs, according to Giannini. “There is still a lot to be discovered on the production side of HTPs. Coaxial technology is one opportunity to open the scenario to different production designs. HTPs are the future. We strongly believe that they will make up the majority of nicotine consumption in the future.”