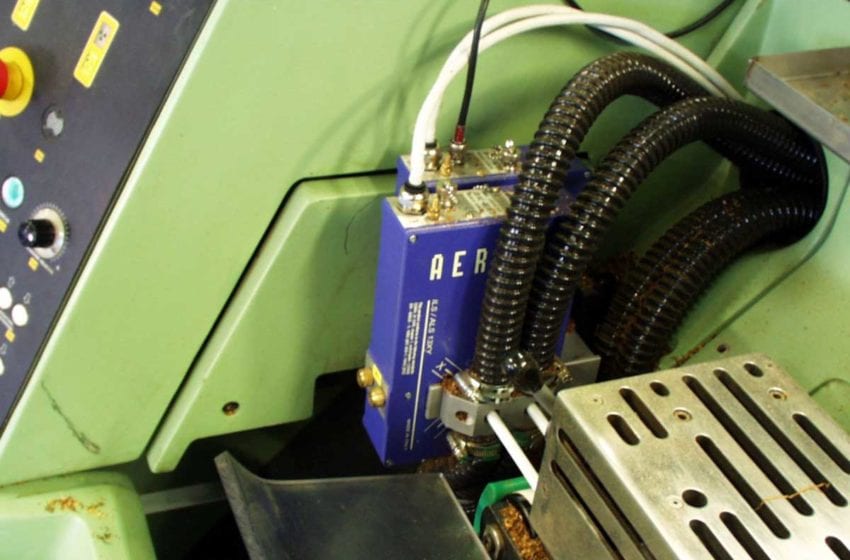

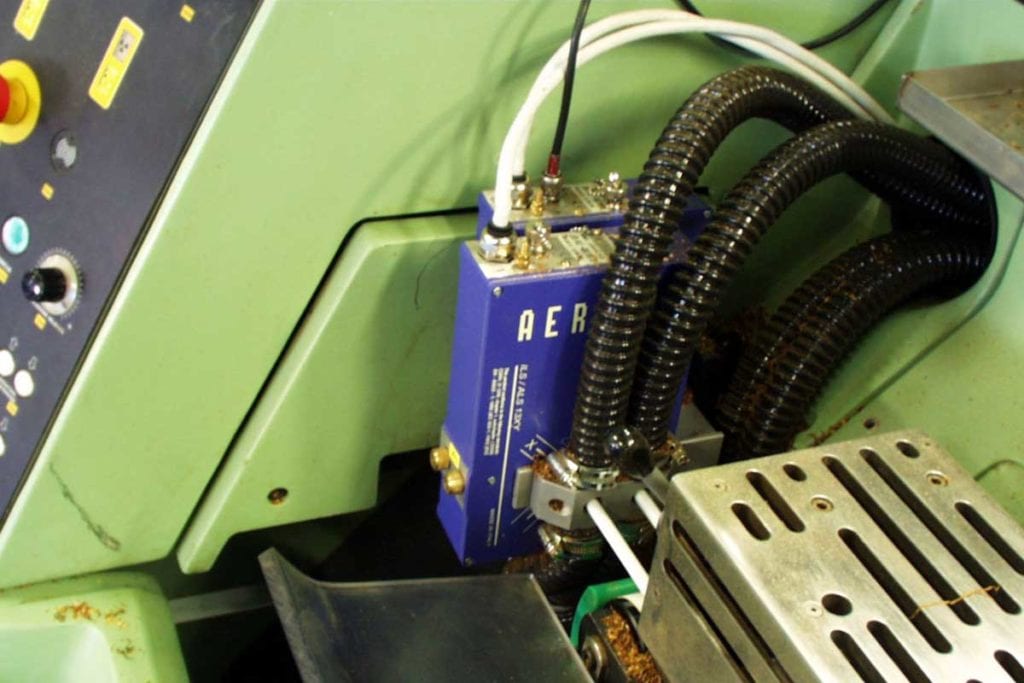

Aeroel by Marposs, a provider of measurement, inspection and test technologies, has launched the Xploreline.XY gauging system for reliable, accurate and contactless diameter gauge control of cigarette or filter-making machines. The Xploreline.XY systems can be installed on-line with either single or double-rod machines and perform continuous diameter monitoring during rod manufacturing to achieve 100 percent inspection of potential dimensional nonconformity.

Each system includes a dual axis Xactum gauge intelligent laser sensor, which provides consistent, accurate measurement of the average rod diameter or rod circumference of fast-moving products. A special patented air-bracket device, specifically suited for on-line applications, is also included, ensuring the gauge self-cleans to protect against tobacco or paper dust.

Diameter measurement data are transmitted to the machine’s numerical control through the serial line, Ethernet or Profibus interface. Using the diameter information, the controller can automatically adjust the machine and keep the rod size within the preset tolerance limits, which improves machine efficiency. Alarm outputs are triggered for any out-of-tolerance part. Off-line applications are also available to check the product size after production.

These compact systems are available in different models and measuring sizes. The Xploreline.XY13 has a measuring field of 13 mm x 13 mm, measurable diameters from 0.1 mm to 10 mm, and a repeatability of ± 0.2 µm and linearity of +/- 0.5 micron. The Xploreline.XY35 has a measuring field of 35 mm x 35 mm, measurable diameters from 0.2 mm to 32 mm, repeatability of ± 0.15 µm and linearity of +/- 1 micron.

Each XLS gauge is programmed with dedicated software along with a display unit and remote control. Overall benefits include:

- Continuous diameter control

- No scrap: real-time inspection allows the system to detect out-of-tolerance trends and return the product back within specification, avoiding any risk of rejects or complaints

- Material savings: keeping the product close to the lowest tolerance limit, considerable savings in materials can be achieved, allowing the cost of the system to be paid back in just a few months

- Process automation: use machines with automatic change of collection reels or systems to coil spools up to a preset weight

- Quality Certification: 100 percent inspection makes random sample checks redundant and allows printing of detailed reports to prove product quality