Innovation, integrity and excellence remain at the core of SWM’s business under the company’s new ownership.

TR Staff Report

In late 2023, a relatively unknown company in the tobacco business, Evergreen Hill Enterprise, purchased the world’s leading supplier of cigarette paper, SWM International, from Mativ Holdings, which had decided that SWM’s tobacco focus would present a more attractive value proposition under new strategic ownership.

Headquartered in Singapore, Evergreen Hill Enterprise is part of an Indonesian-based privately held group of companies serving the tobacco, banking and consumer electronics industries, among other sectors. One of its affiliates is BMJ, a supplier of tobacco packaging and paper with a strong presence in Asia, but the partners made clear that SWM and BMJ would continue to operate independently.

Tobacco Reporter caught up with SWM President and CEO Katrin Hanske to learn what the deal has brought to SWM and its customers.

What have been the biggest changes in SWM’s day-to-day operations since Evergreen Hill Enterprise announced its acquisition in August 2023?

Nothing has changed because they don’t intervene in our day-to-day operations. SWM International is the same company everyone knew before. We still have the same values and culture that our customers, suppliers, partners and employees trust and appreciate. We haven’t changed from a cultural or value perspective, upholding the principles that define how we think, work and interact.

After transitioning from a publicly traded to a privately held company, we relocated our headquarters from Alpharetta to Luxembourg. This shift has granted us greater flexibility to pursue key market opportunities and streamline our strategic decision-making process.

Our priorities remain focused on our customers, unwavering commitment to innovating the industry, empowering our employees, maintaining integrity and striving for excellence in everything we do.

What steps have been taken thus far to integrate SWM into Evergreen Hill Enterprise’s operations?

The acquisition was not focused on integrating SWM but on strengthening Evergreen’s presence in the tobacco market. As a result, we do not have synergies or shared resources with Evergreen or BMJ.

Have there been any senior personnel changes in the wake of the acquisition?

The answer is no. In fact, we have retained our leadership team to ensure continuity, stability and expertise. This stability and accumulated generational knowledge allow us to create high-performance products and tailored solutions.

What advantages has the acquisition brought to SWM customers thus far? What additional benefits do you expect them to receive from the deal in the future?

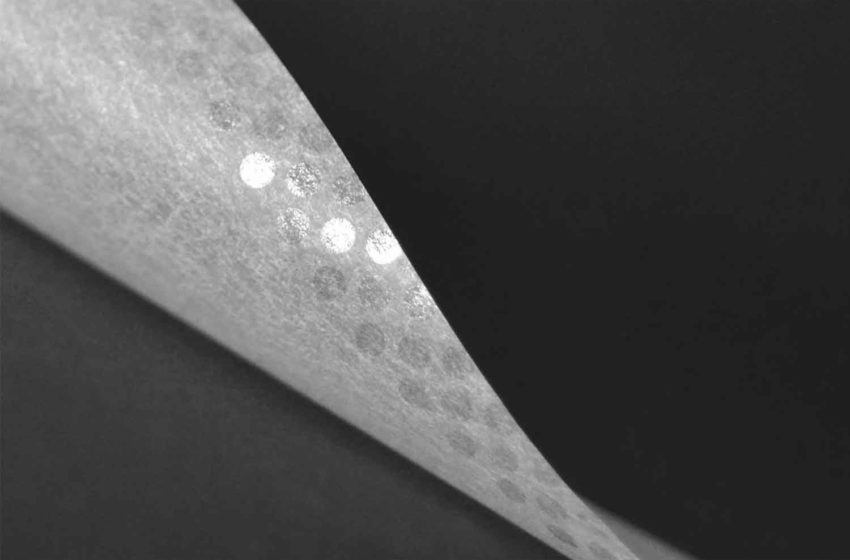

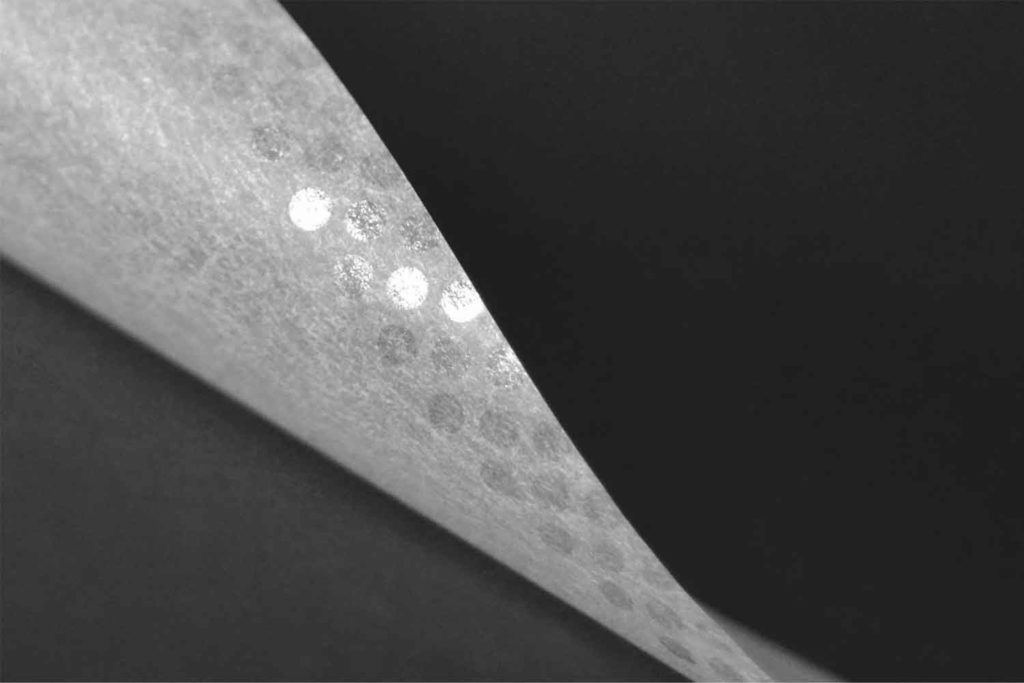

Our focus is accelerating innovation to support our customers’ journey toward reduced-risk products and sustainability. We do this by optimizing the properties of botanicals, natural fibers and lightweight paper solutions. We continue to invest in innovative products and sustainability efforts along the supply chain. This directly benefits our customers, as they can expect us to remain at the forefront of innovation, committed to sustainability and with a strong presence in all geographies.

Does the backing of Evergreen Hill Enterprise enable SWM to pursue projects that it wasn’t able to pursue before? Please explain.

Clearly, we see a significant benefit now of aligned interest in being successful in the tobacco market, allowing us to pursue projects faster than before but also being strategically aligned with the agenda/requirements of our customer base. This includes our recent commitment to the SBTI [Science-Based Targets Initiative] decarbonization program,* which aims to significantly reduce the environmental impact of our operations.

Evergreen Hill Enterprise is also affiliated with BMJ in Indonesia. What do you consider to be the respective strengths of SWM and BMJ? In what respects do they complement one another? What will be the relationship between SWM and BMJ under the Evergreen Hill umbrella?

SWM International and BMJ continue to compete in the marketplace. SWM International is well positioned to support the industry’s shift to reduced-risk products, with a strong presence in the Americas and Europe. BMJ, on the other hand, has a significant foothold in Asia. As a result, looking from the outside, we complement each other with respect to our geographical presence and our product portfolio.

How have customers responded to the acquisition?

The transition to private ownership has been well received by our customers. They see the benefits of our increased focus on meeting their needs within the nicotine and tobacco industry.

What segments of the tobacco paper market will SWM prioritize going forward? Please explain.

SWM International prioritizes customer needs and aligns with their goals. In the traditional/legacy combustible segments, we emphasize performance, high quality and competitive pricing. Our innovation efforts focus on next-generation products as well as offering more sustainable solutions for our existing portfolio.

Are you considering diversification into adjacent categories, given the long-term outlook for tobacco consumption—or is the acquisition an opportunity to double down on your tobacco focus? Please elaborate.

Our company’s proficiency in developing light[weight] and ultra-lightweight papers with specific functionalities extends our reach beyond the tobacco industry. We offer intelligent, sustainable, flexible packaging solutions that are free from plastic and provide barrier effects, heat-seal capability and customizable features. Additionally, our expertise in filtration characteristics presents further opportunities for innovation.

What is next for SWM in terms of manufacturing, product innovation and sustainability?

Our commitment to science-based innovation, manufacturing excellence and the ingenuity of our people drives us to continually develop more sustainable filters that meet taste and sensory expectations. Our scientists and research and development teams collaborate closely with customers to design products with reduced health and environmental impacts. Simultaneously, our operations focus on decarbonizing manufacturing, improving asset efficiency and expanding capabilities to accelerate innovation.

The industry can rely on our dedication to delivering sustainable solutions while maintaining high product quality.