Next year, Hauni plans to launch Prolab, a cigarette making line designed for the tobacco industry’s R&D departments.

Tobacco companies spend considerable amounts of time and money on developing new products. Sooner or later developers need to find out how a new idea performs in a manufacturing context. What do their new products look, feel and taste like? Does the material process well? This is the point when quality parameters need to be defined and preparations must be made for the future manufacturing process.

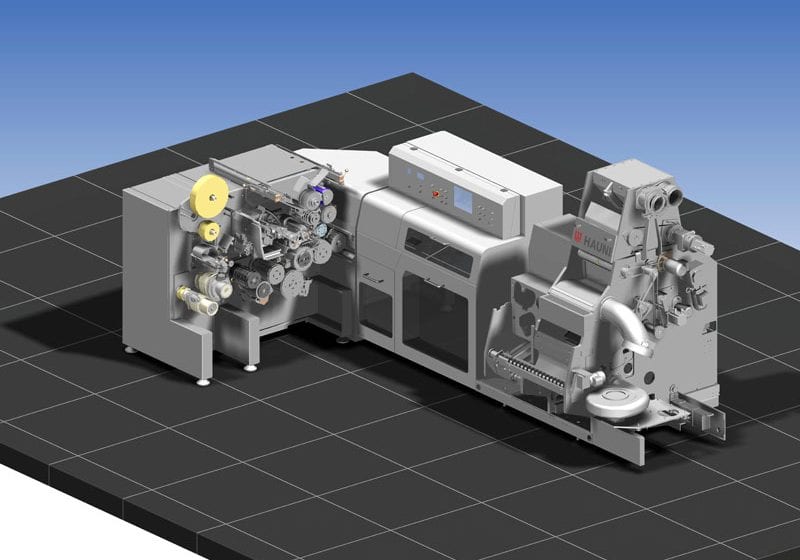

The new easy-to-handle maker line consists of two units, a tobacco rod maker (Prolab-P) and a filter assembler (Prolab-F), which can be used either separately or linked together. At outputs ranging from 100 to 2,000 cpm, Prolab can make cigarettes with diameters from 4.5 to 9 mm and lengths from 60 to 120 mm. Tobacco rods can be cut in lengths from 45 to 105 mm.

The maker lets product developers try out different types of materials and substances. Prolab is also suitable for producing the small volumes for test markets.

Based on Hauni’s venerable Protos line, Prolab includes familiar elements plus the latest features. Any manufacturing process developed on Prolab is directly transferable to industrial-scale production on Hauni cigarette makers.

The machine can also be fitted with a variety of optional Hauni systems, such as NTRM detection, laser perforation and quick size changes.

Prolab replaces the Pilot Maker/Lab-Max linkup that was developed in the 1980s.